Production method of dry-spun acrylic fiber 1.11dtex staple

A 1.11dtex, production method technology, applied in the direction of dry spinning, fiber chemical characteristics, stretch spinning, etc., can solve the problems of no batch production, unstable equipment operation, high production cost, etc., and achieve stable product quality, yarn The effect of normal coloring and increasing the number of fiber crimps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

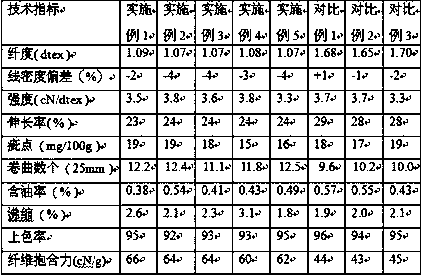

Embodiment 1

[0019] 1) The mass percentage of acrylonitrile is 93.5%, the mass percentage of methyl acrylate is 6%, and the mass percentage of sodium styrene sulfonate is 0.5% to prepare monomer materials and carry out polymerization reaction;

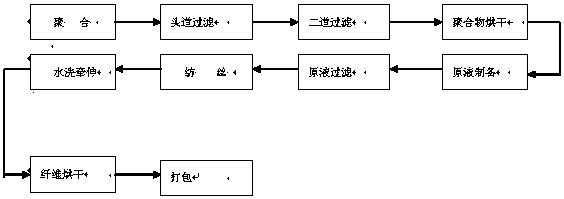

[0020] 2) Carry out the following steps in sequence: primary filtration - secondary filtration - polymer drying - stock solution preparation - stock solution filtration;

[0021] 3) In the spinning step, the temperature of the spinning tunnel is controlled at: the temperature of the air chamber is 330°C, the temperature of the cone body is 205°C, the upper part of the upper tunnel is 170°C, and the lower part of the upper tunnel is 150°C;

[0022] 4) In the water washing and drawing step, the temperature of the first washing tank is 93°C, the second washing tank is 96°C, the fifth washing tank is 98°C, and the eighth washing tank is 99°C. Steam injection pipeline, the outlet steam pressure of the steam injection pipeline is 0.43MPa; the water washi...

Embodiment 2

[0025] 1) The mass percentage of acrylonitrile is 93.6%, the mass percentage of methyl acrylate is 5.0%, and the mass percentage of sodium styrene sulfonate is 0.4%. The monomer material is prepared for polymerization;

[0026] 2) Carry out the following steps in sequence: primary filtration - secondary filtration - polymer drying - stock solution preparation - stock solution filtration;

[0027] 3) In the spinning step, the temperature of the spinning tunnel is controlled at: the temperature of the air chamber is 329°C, the temperature of the cone body is 204°C, the upper part of the upper tunnel is 169°C, and the lower part of the upper tunnel is 148°C;

[0028] 4) In the water washing and drawing step, the temperature of the first washing tank is 92°C, the second washing tank is 95°C, the fifth washing tank is 99°C, and the eighth washing tank is 99°C. Steam injection pipeline, the outlet steam pressure of the steam injection pipeline is 0.46MPa; the water washing and drawi...

Embodiment 3

[0031] 1) The mass percentage of acrylonitrile is 93%, the mass percentage of methyl acrylate is 6.3%, and the mass percentage of sodium styrene sulfonate is 0.7%. The monomer material is prepared for polymerization;

[0032] 2) Carry out the following steps in sequence: primary filtration - secondary filtration - polymer drying - stock solution preparation - stock solution filtration;

[0033] 3) In the spinning step, the temperature of the spinning tunnel is controlled at: the temperature of the air chamber is 331°C, the temperature of the cone body is 206°C, the upper part of the upper tunnel is 172°C, and the lower part of the upper tunnel is 149°C;

[0034] 4) In the water washing and drawing step, the temperature of the first washing tank is 96°C, the second washing tank is 97°C, the fifth washing tank is 98°C, and the tenth washing tank is 99°C. Steam injection pipeline, the outlet steam pressure of the steam injection pipeline is 0.48MPa; the water washing and drawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com