A kind of preparation method of high strength and high crimp viscose fiber

A technology of viscose fiber and crimp, which is applied in the field of high-strength and high-crimp viscose fiber, which can solve the limitation of the development and application of functional viscose fiber, the influence of downstream yarn development, and the slow development of crimp viscose fiber and high-strength viscose fiber And other problems, to achieve the effect of improving curling effect, consolidating effect, improving fiber strength and curling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

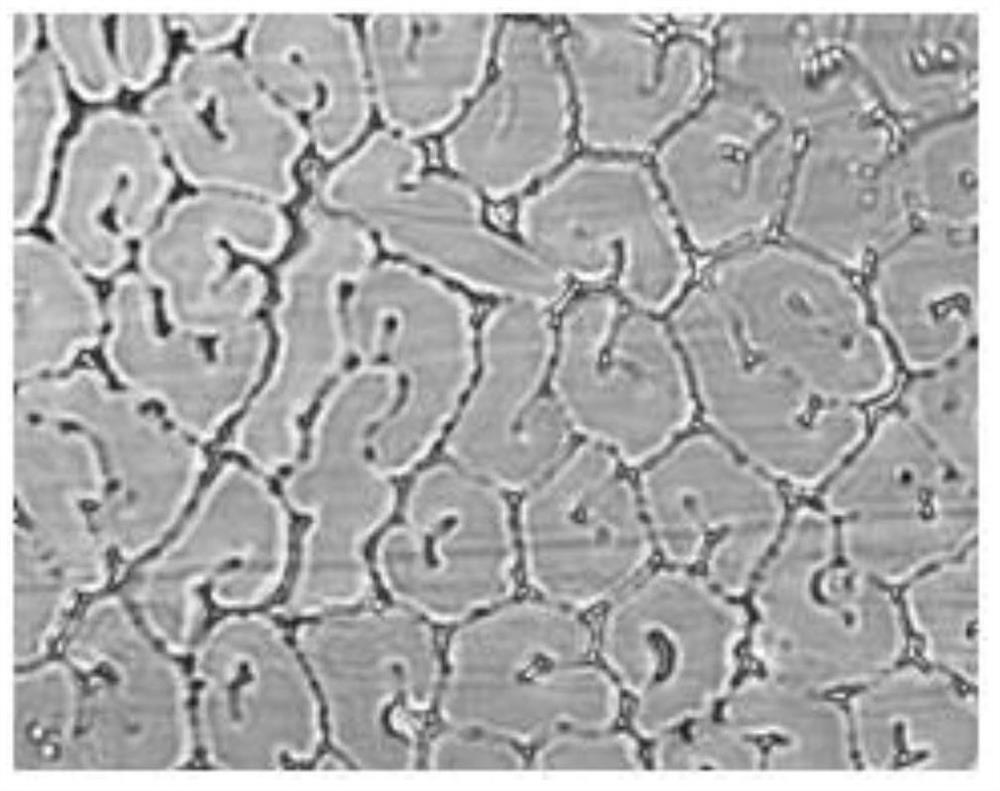

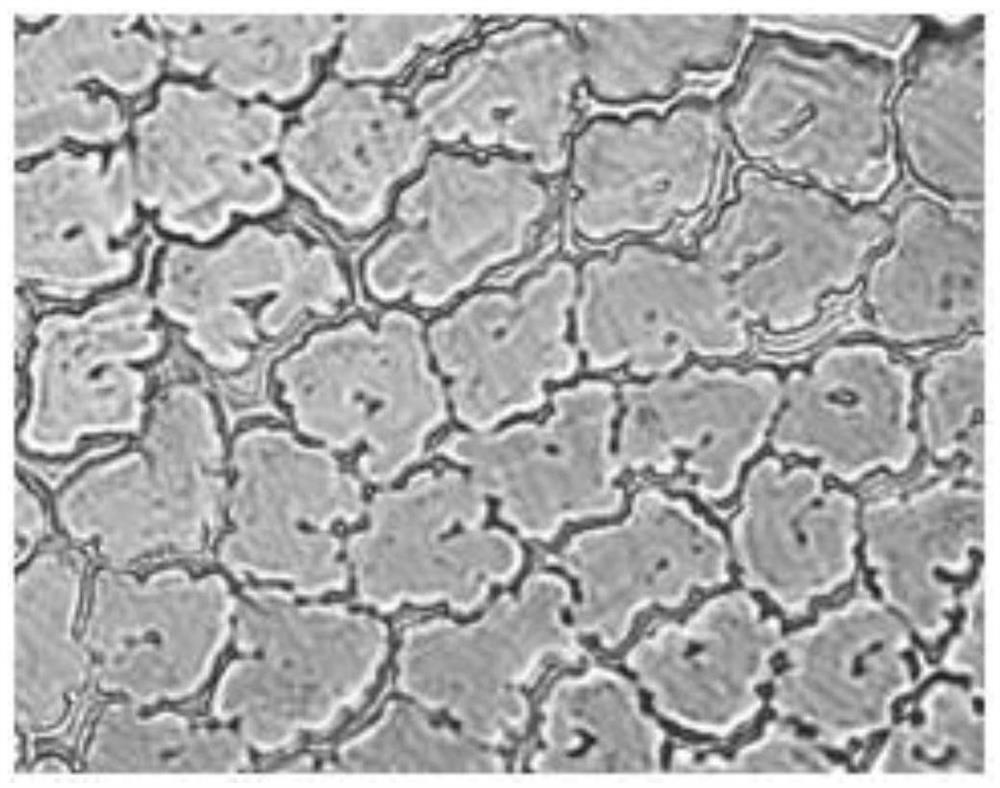

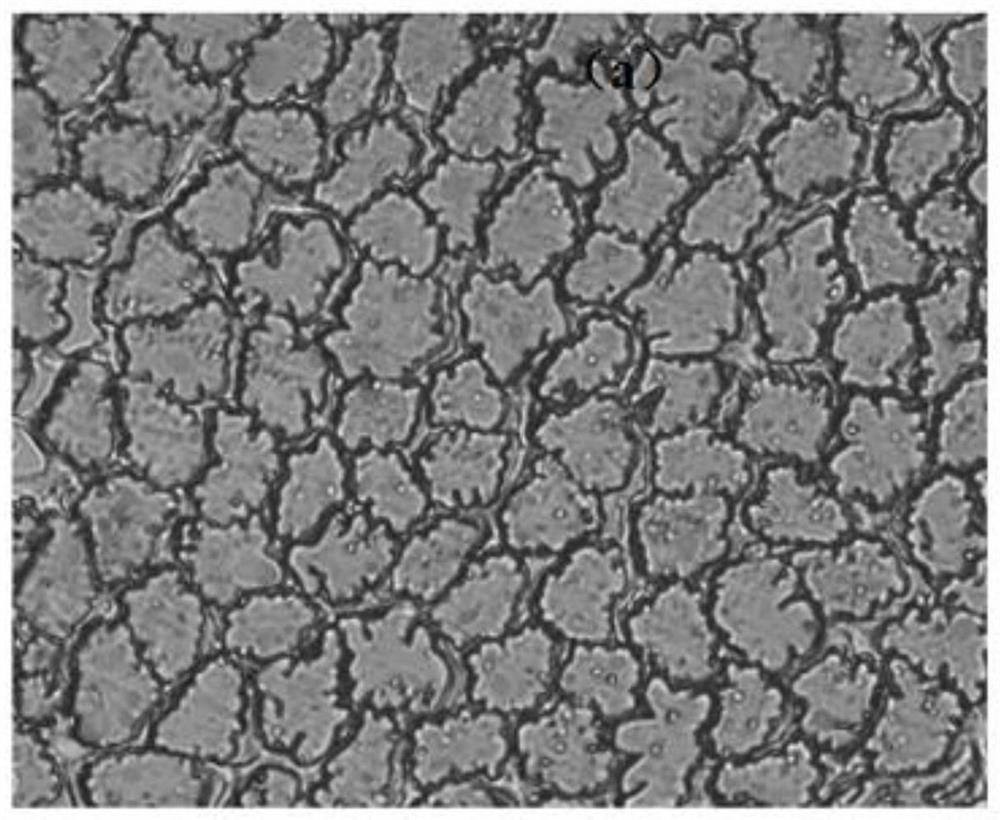

Image

Examples

Embodiment 1

[0043] (1) Preparation of viscose initial solution: the cellulose pulp is prepared through the steps of dipping, pressing, crushing, aging, yellowing, grinding, filtering and degassing to obtain a spinning solution; the index of the spinning solution is: α- Cellulose 8.5wt%, alkali-containing 7.5wt%, viscosity 130s (falling ball method), maturity 12.5ml (ammonium chloride method).

[0044] (2) Preparation of denatured spinning solution: using pre-spinning injection, injecting the denaturant solution into the spinning solution, and mixing uniformly to obtain the denatured spinning solution; the denaturant solution is a melamine solution; The added amount of the denaturant is 5.5wt% relative to the dry basis weight of α-cellulose in the spinning solution.

[0045] (3) Spinning forming: the denatured spinning solution is entered into the spinning bath, and the low spinning speed spinning is formed to obtain the as-spun fiber tow; the spinning bath contains H 2 SO 4 55g / L, ZnSO ...

Embodiment 2

[0049] (1) Preparation of viscose initial liquid: select wood pulp or cotton linter pulp, the degree of polymerization of the cellulose pulp is 750, iron 120ppm, ash content 0.02%; the cellulose pulp is soaked, squeezed, pulverized, aged , yellowing, grinding, filtering, and degassing steps to prepare the spinning solution; the concentration of the lye used for the impregnation is 250g / L, and the temperature of the lye is 25°C; the pressing ratio of the pressing is 1:3.1; The yellowing time, CS 2 The addition amount is 35wt% of the α-cellulose in the alkali cellulose obtained by aging, the yellowing temperature is 25° C., and the yellowing time is 55 minutes. The specifications of the spinning solution are: α-cellulose 8wt%, alkali 7.0wt%, viscosity 125s (falling ball method), maturity 12ml (ammonium chloride method).

[0050] (2) Preparation of denatured spinning solution: Inject the denaturant into the prepared spinning solution through a plunger metering pump by means of p...

Embodiment 3

[0055] (1) Preparation of viscose initial liquid: select wood pulp or cotton linter pulp, the degree of polymerization of the cellulose pulp is 800, iron 110ppm, ash content 0.05%; the cellulose pulp is soaked, squeezed, pulverized, aged , yellowing, grinding, filtering, and degassing steps to prepare the spinning solution; the concentration of the lye used for impregnation is 255g / L, and the temperature of the lye is 22°C; the squeezing ratio of the pressing is 1:3.0; The yellowing time, CS 2 The addition amount is 33wt% of the amount of α-cellulose in the alkali cellulose obtained by aging, the yellowing temperature is 23° C., and the yellowing time is 56 minutes. The indicators of the spinning solution are: α-cellulose 7.8wt%, containing 7.2wt% alkali, viscosity 130s (falling ball method), maturity 13ml (ammonium chloride method).

[0056] (2) Preparation of denatured spinning solution: Inject the denaturant into the prepared spinning solution through a plunger metering pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| number of curls | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com