A steel mill gas sulfur content soft measurement method

A technology of sulfur content and soft measurement, which is applied in special data processing applications, instruments, electrical digital data processing, etc. The effect of value, simplification of the solution process, and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will now be described in further detail.

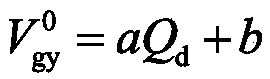

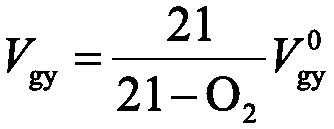

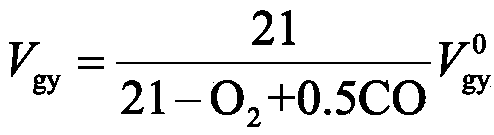

[0032] A soft measuring method for the sulfur content of steel plant gas, characterized in that: by obtaining raw data, and calculating and processing the data, the sulfur content of the gas is obtained by solving, and the specific steps are as follows:

[0033] Step 1, obtain the raw data required for soft measurement; the obtained raw data include but not limited to: SO in flue gas 2 Emission concentration, flue gas oxygen content, gas calorific value.

[0034] In this example, the SO in the flue gas 2 Emission concentration is SO in dry flue gas 2 Emission concentration, flue gas oxygen content is the oxygen content in dry flue gas.

[0035] In this embodiment, the gas calorific value is the lower calorific value of the gas dry basis.

[0036] In this example, the flue gas oxygen content and SO 2 The emission concentration shares the measuring point, or its measuring point is located close to the S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com