Quasi-solid electrolyte for protecting lithium negative electrode and preparation method thereof

A liquid electrolyte and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as unfavorable large-scale production, thin alumina coating, liquid electrolyte leakage, etc., and achieve good thermal stability and chemical stability. Stability, inhibition of lithium dendrite generation, effect of wide electrochemical stability window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) In a glove box filled with a protective gas with a purity greater than or equal to 99% argon and a moisture content of less than 1ppm, add 0.41g of lithium bistrifluoromethanesulfonimide to 2.00g of N-methyl, propylpyrrolidine Stir in the bistrifluoromethanesulfonimide salt for 24 hours to obtain a uniform and transparent liquid electrolyte; add 2.00ml of aluminum sec-butoxide to the liquid electrolyte and stir for 3 minutes to obtain a milky white uniform thick liquid; finally add 2.00ml of formic acid and stir to make Mix them evenly to obtain a reaction system;

[0036] (2) Allow the reaction system to stand in the glove box for 48 hours, then remove it and place it in a vacuum drying oven with a relative vacuum of -80KPa, and dry it at 80°C for 5 days to obtain a reaction system according to the present invention. Quasi-solid electrolytes for lithium anode protection.

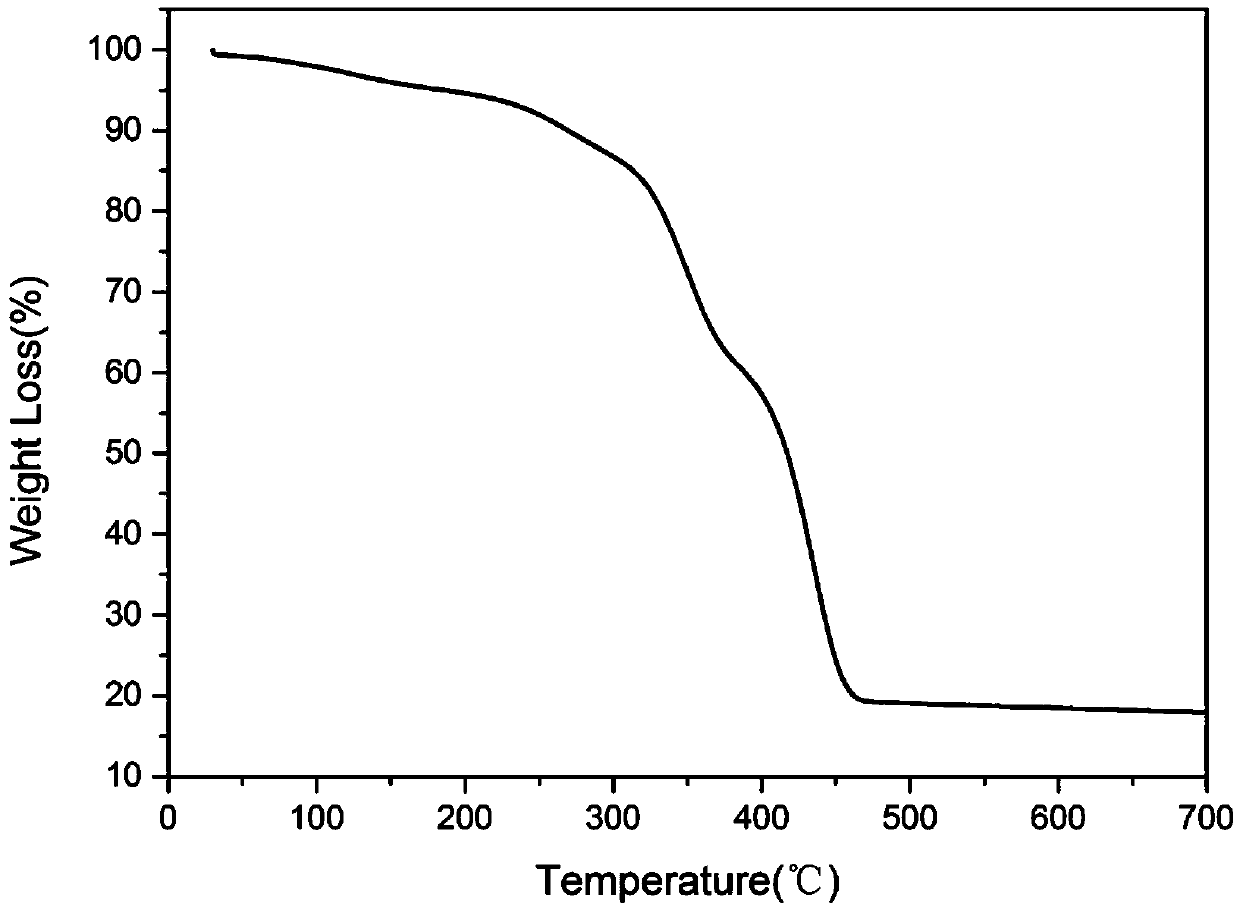

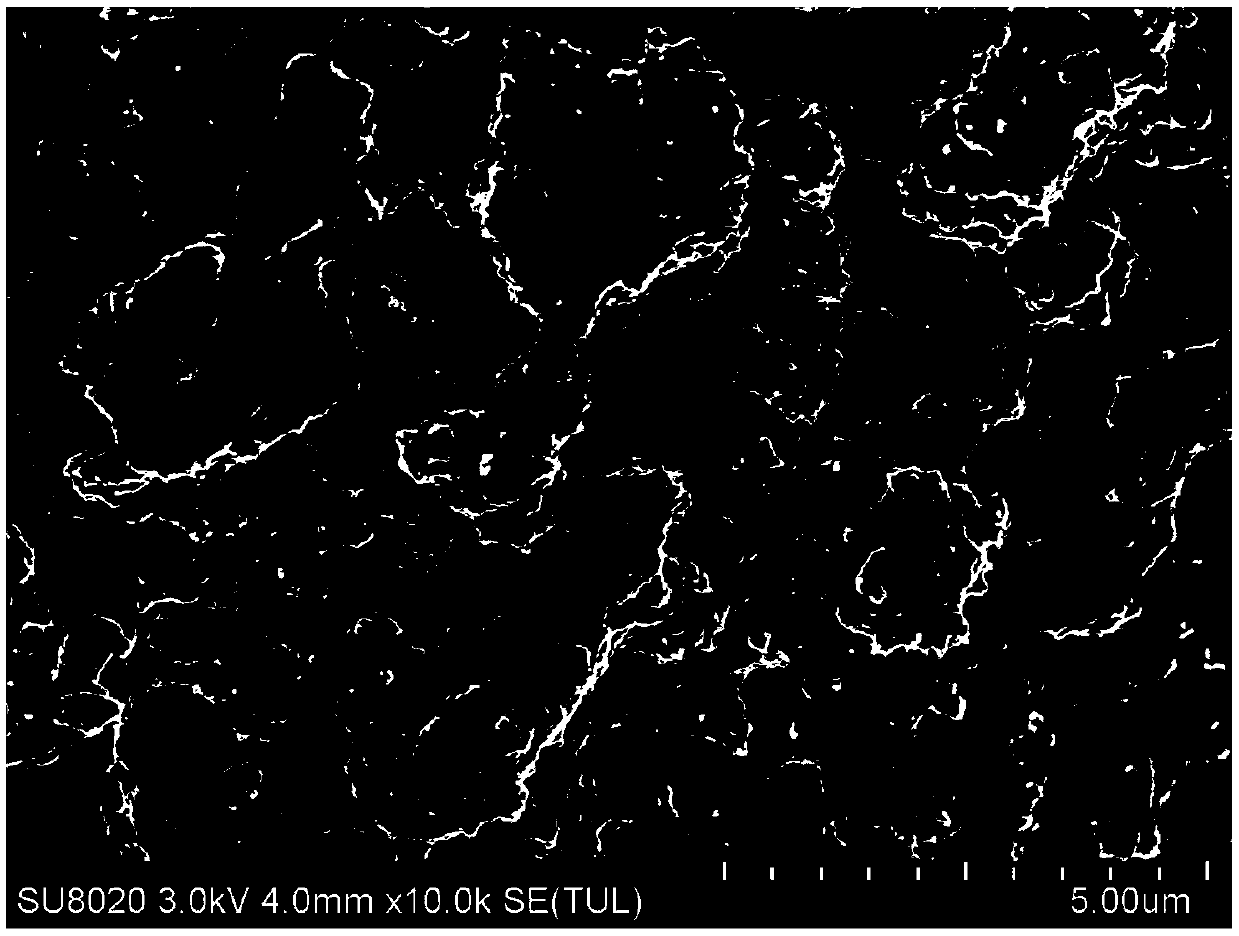

[0037] A kind of quasi-solid electrolyte used for lithium negative electrode protection prep...

Embodiment 2

[0043] (1) In a glove box filled with a protective gas with a purity greater than or equal to 99% argon and a moisture content of less than 1ppm, add 0.41g of lithium bistrifluoromethanesulfonimide to 2.00g of N-methyl, propylpyrrolidine Stir in the bistrifluoromethanesulfonimide salt for 24 hours to obtain a uniform and transparent liquid electrolyte; add 2.50ml of aluminum sec-butoxide to the liquid electrolyte and stir for 3 minutes to obtain a milky white uniform thick liquid; finally add 2.85ml of formic acid and stir to make Mix them evenly to obtain a reaction system;

[0044] (2) Allow the reaction system to stand in the glove box for 48 hours, then remove it and place it in a vacuum drying oven with a relative vacuum of -80KPa, and dry it at 80°C for 5 days to obtain a reaction system according to the present invention. Quasi-solid electrolytes for lithium anode protection.

[0045] A kind of quasi-solid electrolyte used for lithium negative electrode protection prep...

Embodiment 3

[0051] (1) In a glove box filled with a protective gas with a purity greater than or equal to 99% argon and a moisture content of less than 1ppm, add 0.41g of lithium bistrifluoromethanesulfonimide to 2.00g of N-methyl, propylpyrrolidine Stir in the bistrifluoromethanesulfonimide salt for 24 hours to obtain a uniform and transparent liquid electrolyte; add 3.00ml aluminum sec-butoxide to the liquid electrolyte and stir for 3 minutes to obtain a milky white uniform thick liquid; finally add 3.50ml formic acid and stir to make Mix them evenly to obtain a reaction system;

[0052] (2) Let the reaction system stand still in the glove box for 48h, then remove it and place it in a vacuum oven with a relative vacuum of -80KPa, and dry it at 80°C for 5d to obtain a compound for use in the present invention. A quasi-solid electrolyte for lithium anode protection.

[0053] A kind of quasi-solid electrolyte used for lithium negative electrode protection prepared in this example is teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com