Wet-dry process compounded technology for regenerating and recovering waste and old copper-bismuth catalyst

A copper-bismuth catalyst, composite regeneration technology, applied in catalyst regeneration/reactivation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as environmental pollution, activity reduction, difficulty, etc. , to achieve the effect of reducing production cost, high regeneration efficiency and improving recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

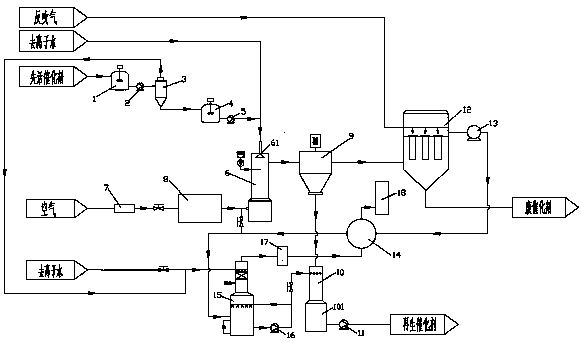

[0019] Such as figure 1 As shown, the invention discloses a dry-wet composite regeneration process for recovering waste copper-bismuth catalyst, comprising the following steps:

[0020] Step 1): Slurry delivery: unload the catalyst slurry from the production equipment into the first stirring buffer tank 1 at a flow rate of 20kg / h, and control the concentration of the slurry to 1%, and then transport the slurry to the hydrocyclone through the first delivery pump 2 In the hydrocyclone 3, the catalyst slurry in the lower layer treated by the hydrocyclone 3 is concentrated to 10% and enters the second stirring buffer tank 4, and the supernatant of the hydrocyclone 3 is transported to the water replenishment port of the scrubber 15 through a pipeline.

[0021] Step 2): Activation treatment: the catalyst slurry in the lower layer is transported to the top feed port of the activation furnace 6 through the second delivery pump 5 and atomized. The top of the activation furnace 6 is pro...

Embodiment 2

[0026] Such as figure 1 As shown, the invention discloses a dry-wet composite regeneration process for recovering waste copper-bismuth catalyst, comprising the following steps:

[0027] Step 1): Slurry delivery: Unload the catalyst slurry from the production equipment into the first stirring buffer tank 1 at a flow rate of 60kg / h, and control the concentration of the slurry to 20%, and then transport the slurry to the hydrocyclone through the first delivery pump 2 In the hydrocyclone 3, the lower catalyst slurry treated by the hydrocyclone 3 is concentrated to 40% and enters the second stirring buffer tank 4, and the supernatant of the hydrocyclone 3 is transported to the water replenishment port of the scrubber 15 through a pipeline.

[0028]Step 2): Activation treatment: The catalyst slurry in the lower layer is transported to the feed inlet at the top of the activation furnace 6 through the second delivery pump 5 and atomized. The top of the activation furnace 6 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com