Technology for bonding water-soluble film and water-soluble nonwoven fabric

A water-soluble film and non-woven fabric technology, applied in textiles and papermaking, lamination, layered products, etc., can solve problems such as the difficulty of glue decomposition, and achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] The first preferred embodiment:

[0032] A bonding process for a water-soluble film and a water-soluble non-woven fabric, comprising the following steps:

[0033] (1) Prepare water-soluble film and water-soluble non-woven fabric. Among them, the dissolution temperature of the finished water-soluble film is 20°C to 100°C. Water-soluble non-woven fabric can be selected from a variety of water-soluble fabrics.

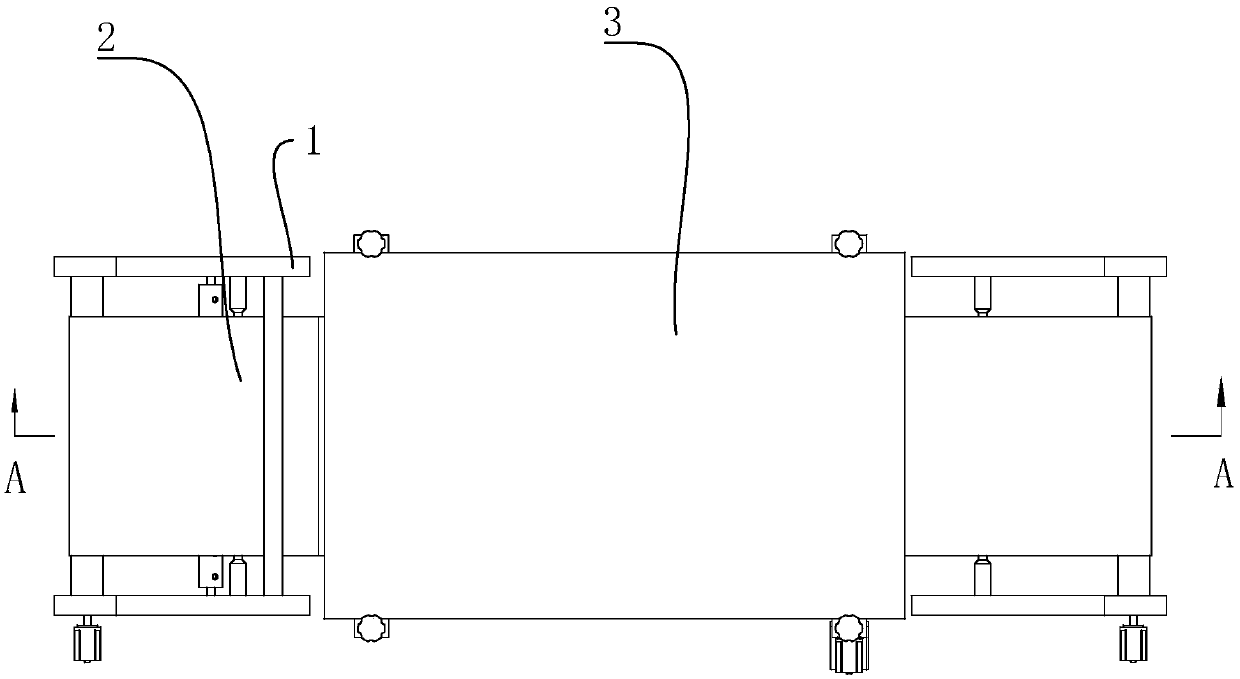

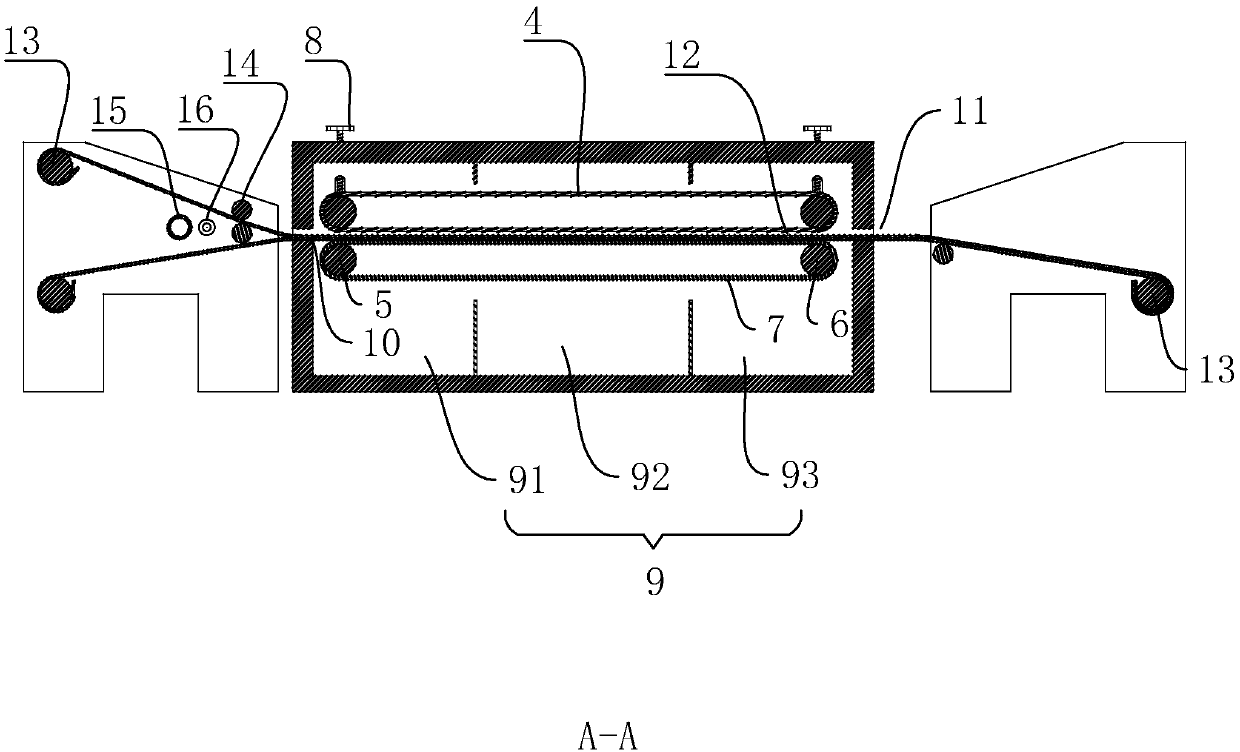

[0034] (2) The fusible interlining machine is selected as the bonding equipment, and the fusible interlining machine includes at least:

[0035] Conveying device 2, conveying device 2 has at least two groups of conveyor belts 4 that conflict up and down and form conveying channel 12;

[0036] Heating device 3, the heating device 3 is an oven 9 for heating the transmission channel 12;

[0037] The guide roller assembly 13 is arranged on the fron...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap