Method for preparing polysaccharide modified nanometer selenium on large scale and application

A large-scale preparation, nano-selenium technology, applied in the field of selenium resource utilization, can solve the problems of environmental pollution, complicated process, high cost of nano-selenium, etc., and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

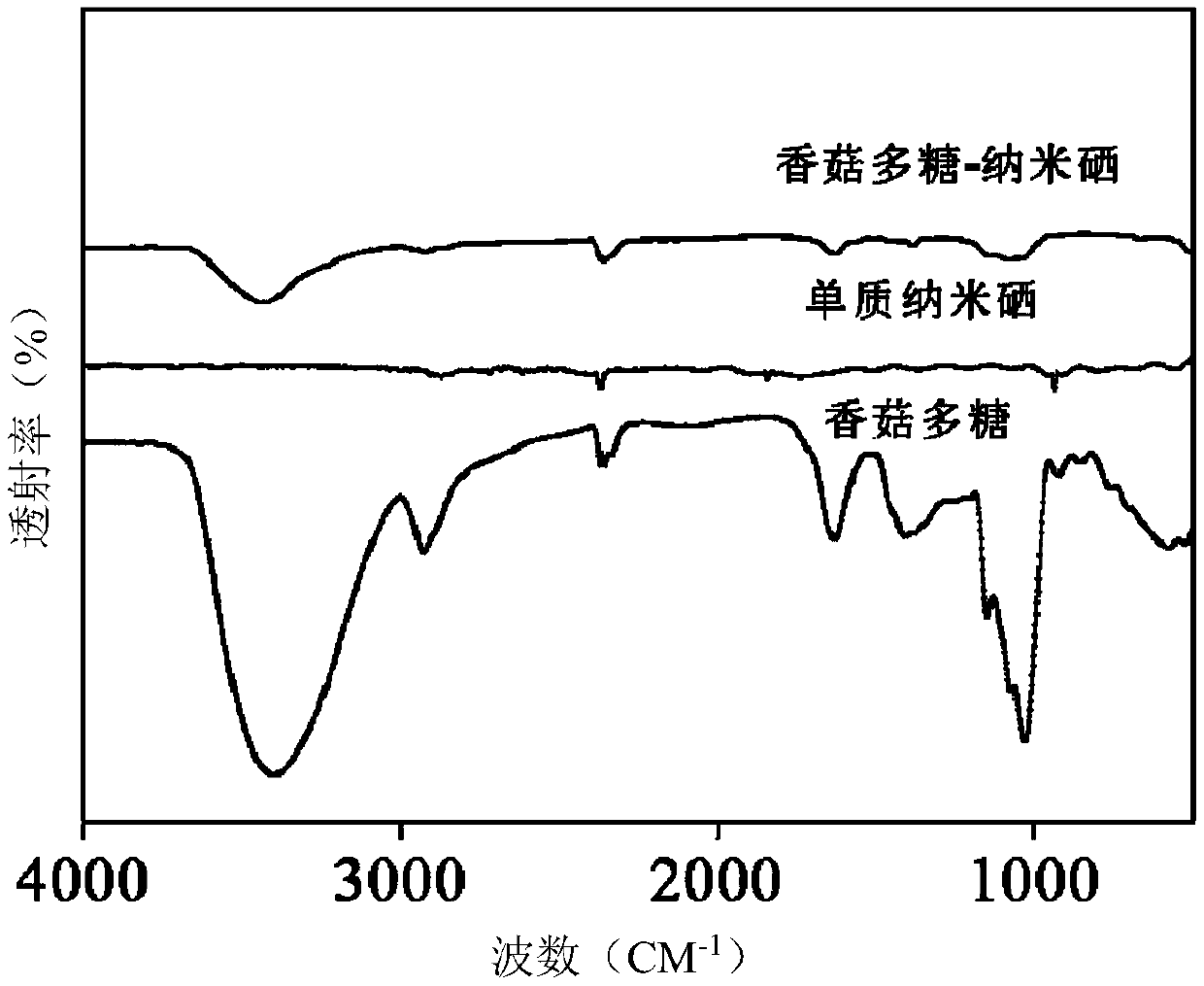

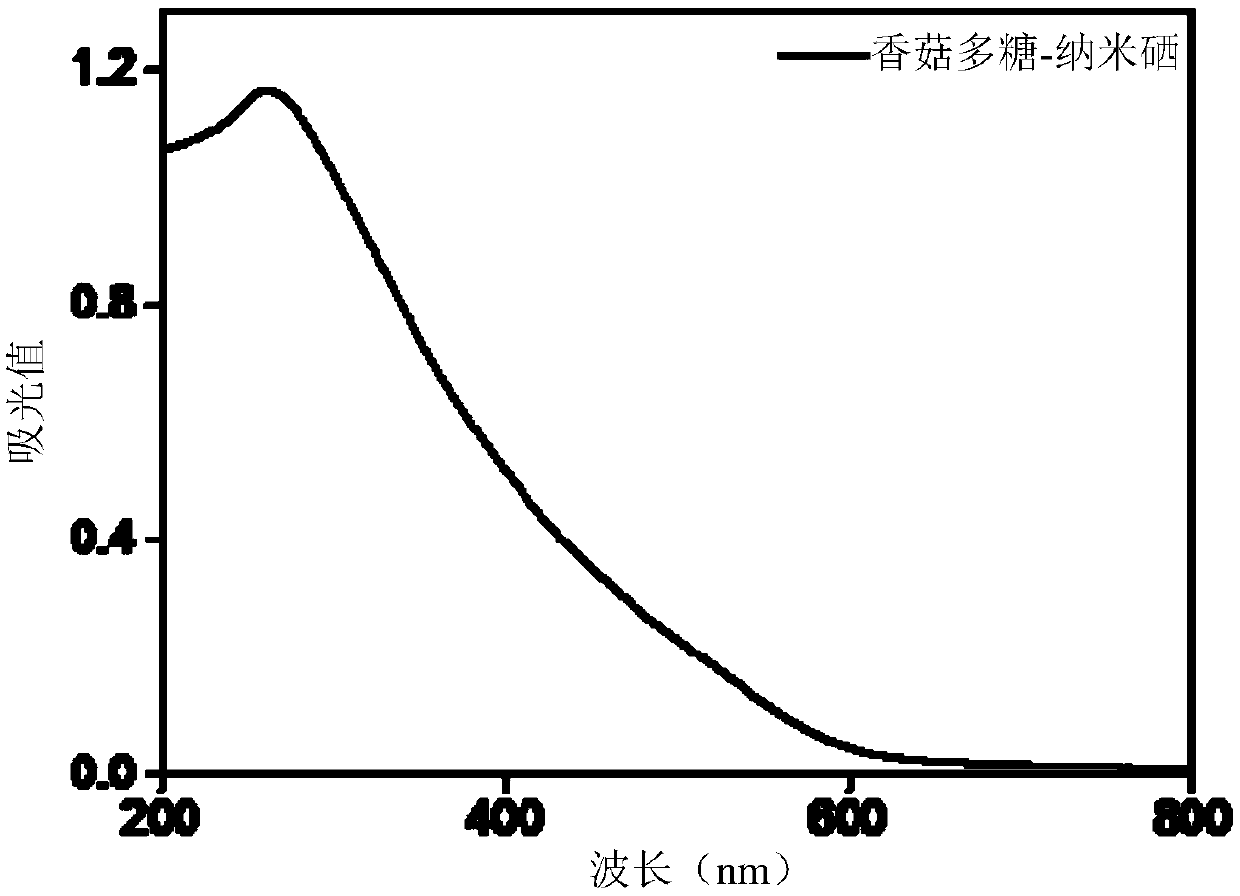

Method used

Image

Examples

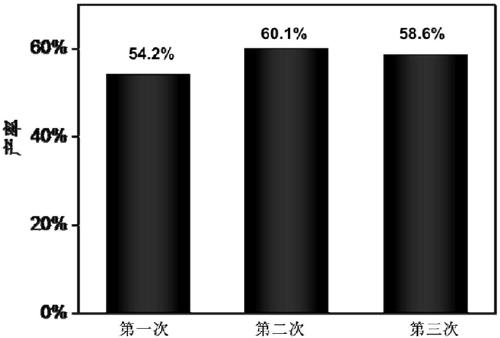

Embodiment 1

[0044]In 500 liters of reactors, the lentinan (Shaanxi Senfu Natural Products Co., Ltd., 1kg / bag 50%, CAS No. 37339-90-5) aqueous solution and 100L concentration of 10g / L lentinan (Shaanxi Senfu Natural Products Co., Ltd., CAS No. 37339-90-5) and 100L concentration are mixed in the 80mM Vc aqueous solution uniform. Then pump the mixed solution into a 500L fermenter, add water to 450L, start the fermenter, maintain the stirring speed at 90 rpm and stir for 5min, and continue to mix the lentinan aqueous solution and the Vc aqueous solution. Then slowly add 30 L of sodium selenite aqueous solution containing 700 g with a low-pressure water pump. Close the fermenter, set the number of revolutions to 70 revolutions / min, and react for 8 hours under the conditions of a pressure of 0.1 MPa and a reaction temperature of 50°C. After the reaction is completed, the prepared lentinan-modified nano-water selenium solution is exported through the outlet of the fermenter and placed in a clea...

Embodiment 2

[0049] In a 25 ml reactor, nano-selenium was prepared with chitosan (Sinopharm Chemical Reagent Co., Ltd., biochemical reagent, batch number 20160525, 100 g / bottle) as a modifier. First, mix 0.05g chitosan with 5mL 80mM Vc aqueous solution, add 0.2mL 1% (v / v) acetic acid to dissolve, then add 5mL water, and stir for 5min at 90 rpm. Then add 5 mL of sodium selenite aqueous solution with a concentration of 23.3 g / L, set the rotation speed to 70 rpm, and react for 8 hours under the conditions of 0.1 MPa and 50° C., and the obtained solution is a transparent orange solution. Finally, the chitosan-modified nano-selenium aqueous solution is filtered through a filter membrane (molecular weight cut-off: 10KD) to obtain the purified chitosan-modified nano-selenium aqueous solution, which is orange in appearance and stored at 4°C.

[0050] After the obtained orange solution was placed for 120 hours, a large amount of gray-red flocculent precipitates appeared, which could not be disperse...

Embodiment 3

[0052] In a 25 ml reactor, carboxymethyl chitosan (substitution degree greater than 80%, Mackin) was used to replace the acid-soluble chitosan in Example 2 to prepare nano-selenium. First, mix 0.05 g of carboxymethyl chitosan with 5 mL of 80 mM Vc aqueous solution, then add 5 mL of water, and stir at 90 rpm for 5 min. Then add 5 mL of sodium selenite aqueous solution with a concentration of 23.3 g / L, set the rotation speed to 70 rpm, and react at 0.1 MPa and 50° C. for 8 h. Finally, the carboxymethyl chitosan-modified nano-selenium water solution was filtered through a filter membrane (molecular weight cut-off: 10KD) to obtain the purified carboxymethyl chitosan-modified nano-selenium water solution, which was stored at 4°C.

[0053] The experimental results show that although carboxymethyl chitosan is easy to dissolve in water, when the Vc aqueous solution is added dropwise to the mixed solution of carboxymethyl chitosan and sodium selenite, nano-selenium quickly coagulates, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com