Iron cycle drive based device and method for ammonia nitrogen anaerobic in-situ treatment

A technology of in-situ treatment and iron recycling, which can be used in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., and can solve problems such as inadvisability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principle of the invention is based on the principle of NDFO coupling Feammox, adding nitrate to Feammox system regularly, and using nitrate as the final electron acceptor of anaerobic ammonia oxidation to remove high-concentration ammonia nitrogen.

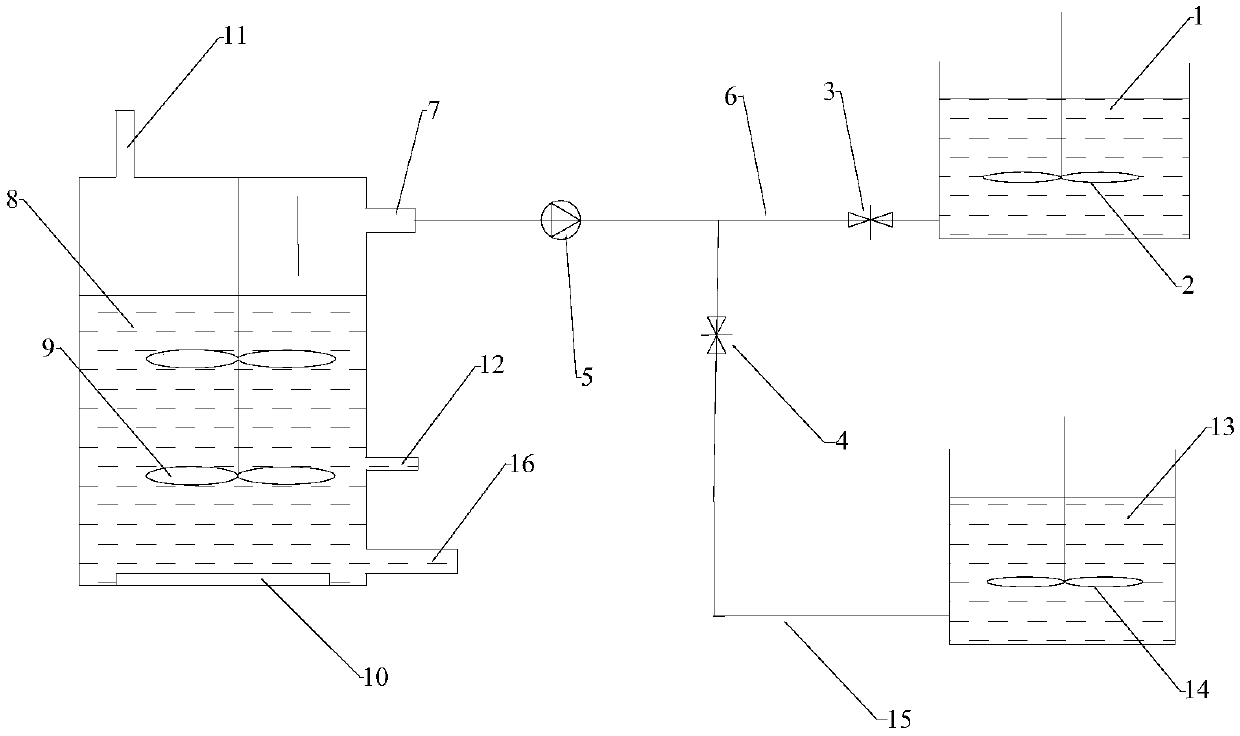

[0019] The experimental device used in the present invention is as follows figure 1 Shown: There is a sample injection cell 1 with a stirrer i-2 fixed above. One end of the pipeline i-6 equipped with the valve i-3 and the peristaltic pump 5 is connected to the lower side of the sampling tank 1 and the other end is connected to the feed port 7 above the fermentor 8 . The upper cover of the fermentation tank 8 is provided with an air outlet pipe 11 upward and a stirrer ii-9 is fixed downward. An aeration device 10 is fixed to the bottom of the fermentation tank 8 . The lower side of the fermentation tank 8 is provided with a sludge discharge valve 16 and the middle and lower side is provided with a drain valve 12 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com