Decentralized type sewage and sludge biochemical treatment system

A biochemical treatment, decentralized technology, applied in biological sludge treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of insufficient sewage filtration, clogging and hardening of the filter layer, and high cost. Achieve good hydraulic conductivity and microbial habitat, prevent filter bed hardening, and facilitate long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

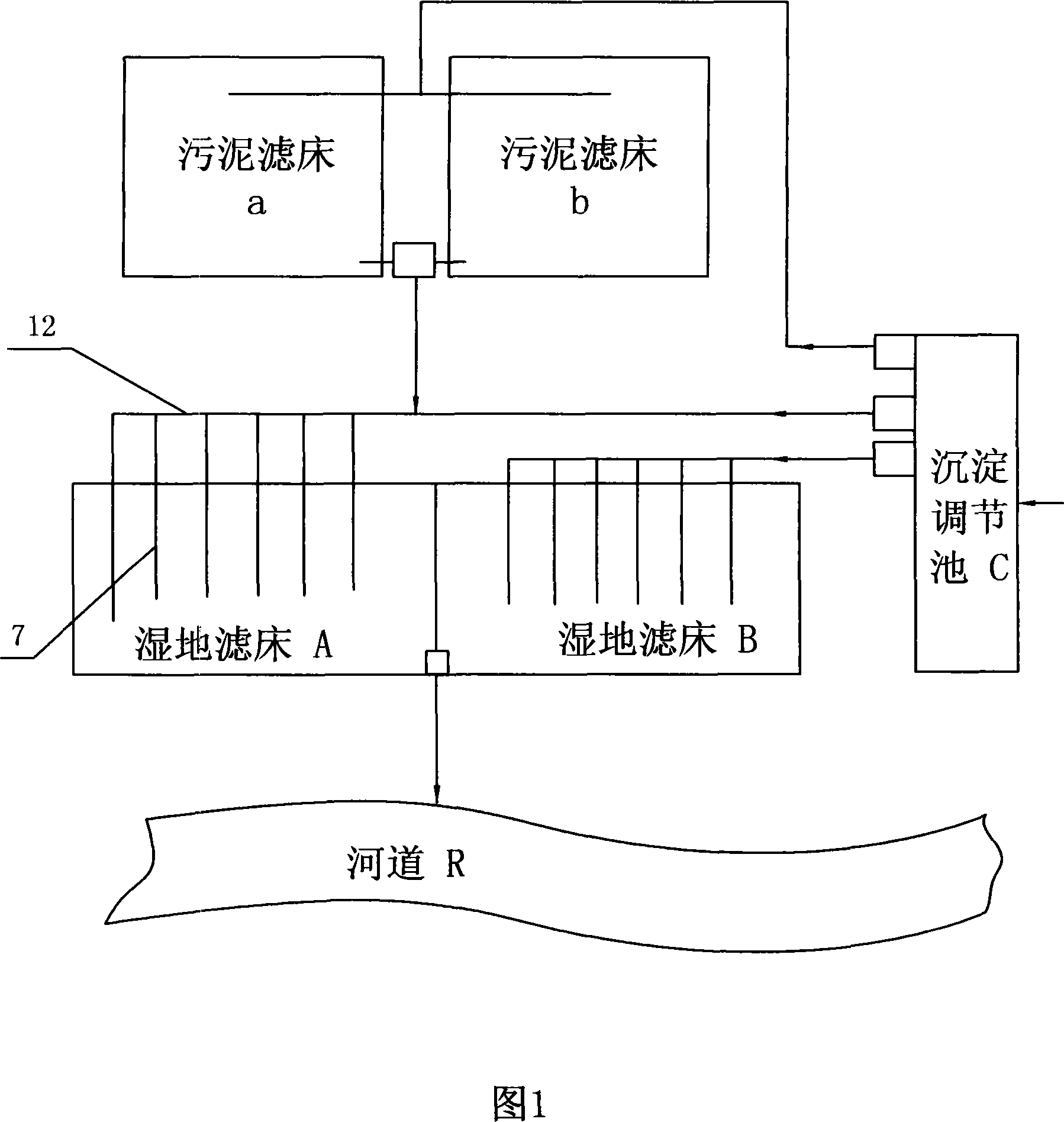

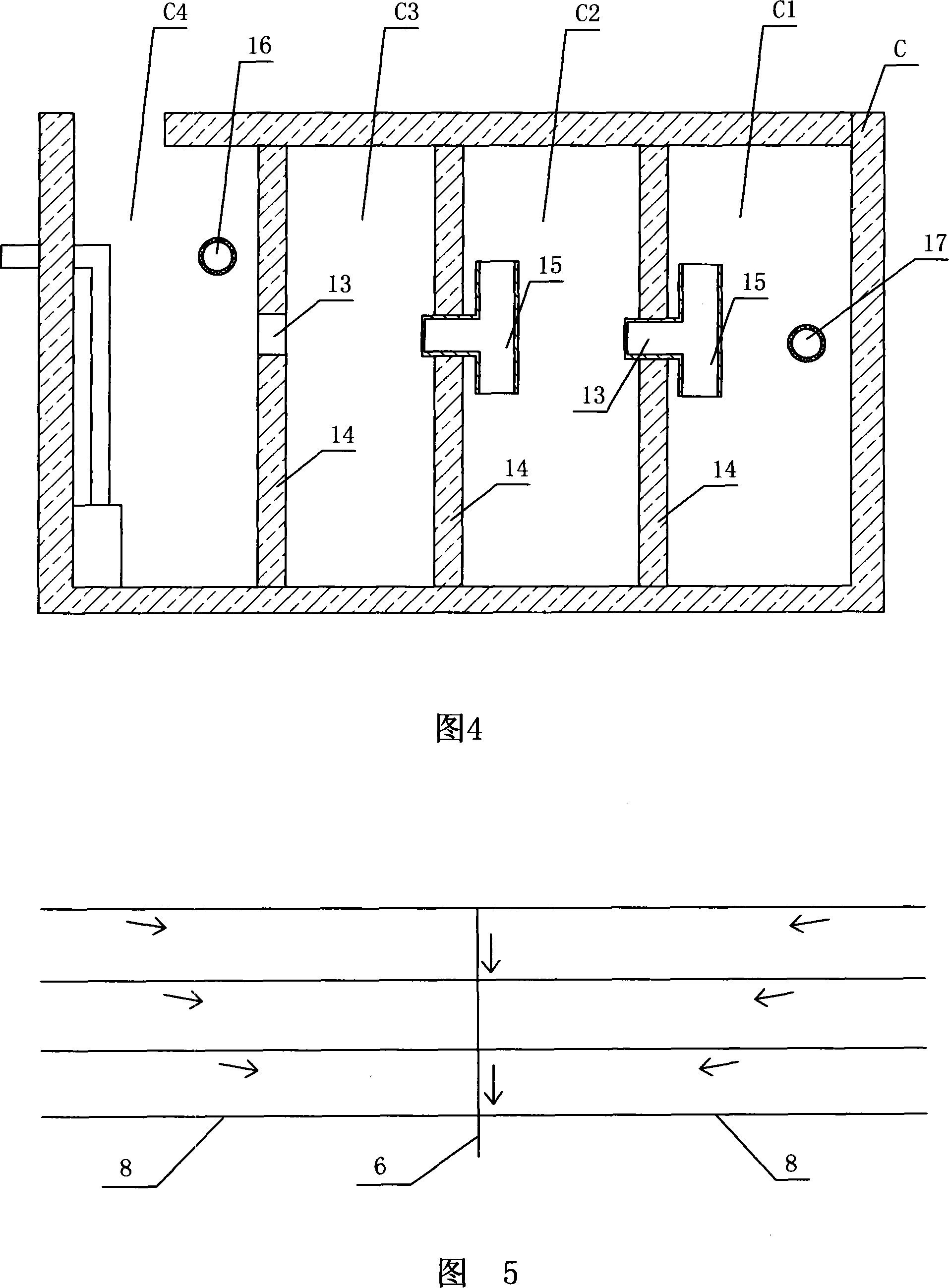

[0027] As shown in Figure 1, the distributed sewage and sludge biochemical treatment system of this embodiment includes: a biochemical filter bed A for biochemical treatment of sewage and a sedimentation adjustment tank C connected to the sewage water source adjacent to the biochemical filter bed A The surface of the biochemical filter bed A is provided with a water distribution pipe 7, and the water distribution pipe 7 is connected to the water pump in the sedimentation adjustment tank C through the water distribution main pipe 12; A sludge pump is arranged inside, and the sludge pump is connected with the sludge filter bed a through a pipeline.

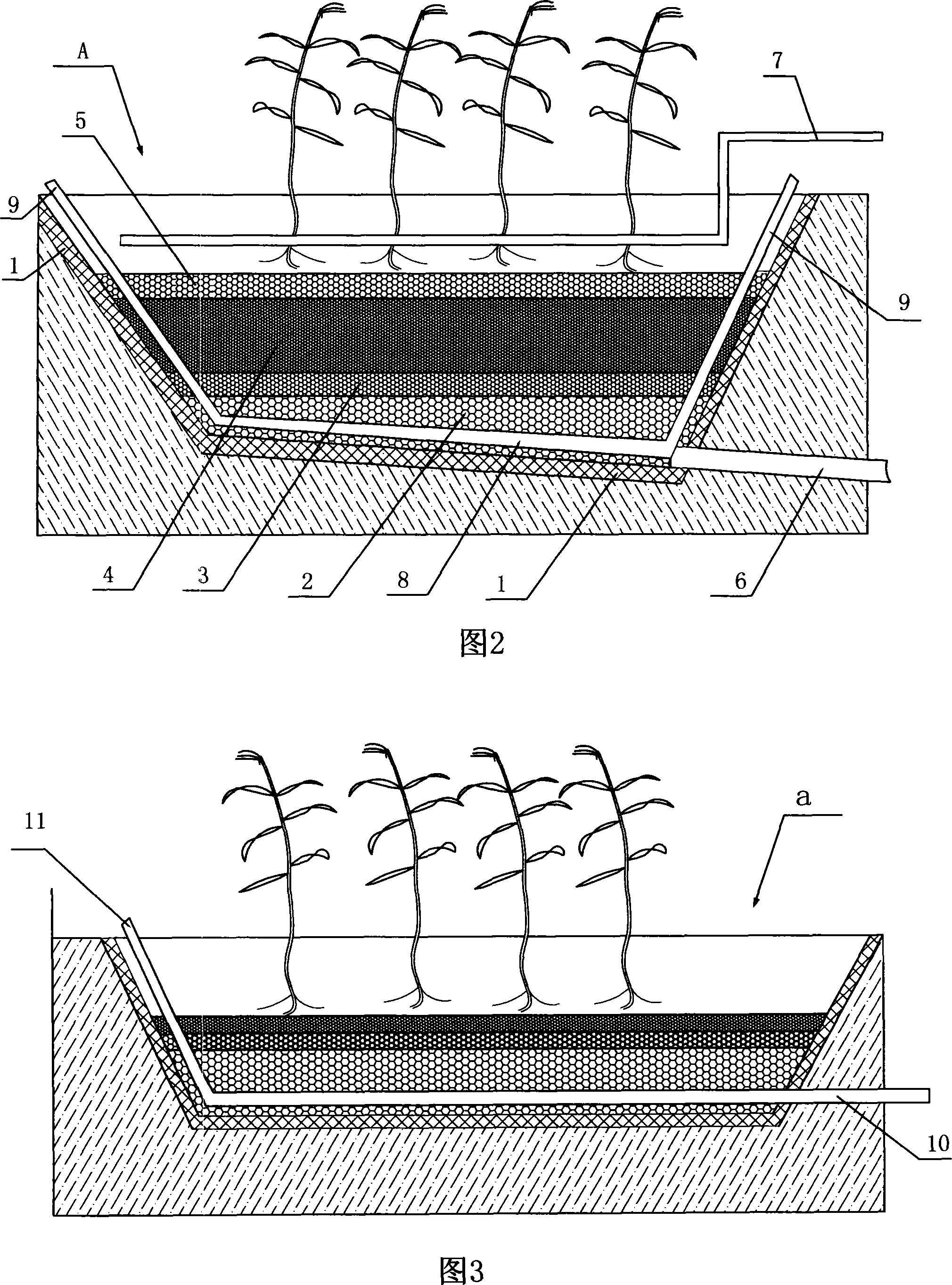

[0028]As shown in Fig. 2, biochemical filter bed A comprises the depth of digging on the surface at the biochemical filter bed pit of 80cm (other embodiments are 70cm or 90cm), and the surface of biochemical filter bed pit is laid with anti-seepage layer 1, from biochemical filter bed pit The bottom surface of the bottom surface is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com