Comprehensive treatment method and apparatus for exhaust gas pollutants of marine diesel engine

A marine diesel engine and comprehensive treatment technology, which is applied in the direction of combined devices, gas treatment, separation methods, etc., can solve the problems of increased cylinder wear, inability to remove, easy poisoning and failure of catalysts, etc., to improve the reaction rate, reduce fresh water consumption, and gas The effect of sufficient liquid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

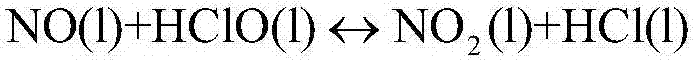

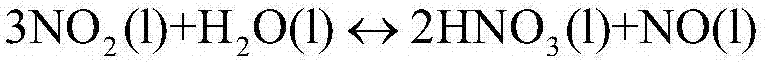

[0030] A comprehensive treatment method for marine diesel engine exhaust gas pollutants, which realizes the treatment of SO in marine diesel engine exhaust x , NO x The removal of various pollutants such as , PM, etc. has the following steps:

[0031] S1. The marine diesel exhaust gas that has been cooled down enters the supergravity reactor, and the sulfur oxides and particulate matter in the marine diesel engine exhaust gas are removed by wet washing. The washing liquid in the supergravity reactor is sodium hydroxide, sodium carbonate, carbonic acid An aqueous solution of one or several alkaline compounds in sodium hydrogen, magnesium hydroxide, calcium hydroxide, the water in the aqueous solution is fresh water or seawater, and the involved chemical reaction process is as follows:

[0032] SO 2 (g)→SO 2 (l)

[0033] SO 2 (l)+2OH - (l)→SO 3 2- (l)+H 2 O(l)

[0034] SO 3 2- (l)+2OH - (l)→SO 4 2- (l)+H 2 O(l);

[0035] S2. The exhaust gas obtained by the high-gr...

Embodiment 2

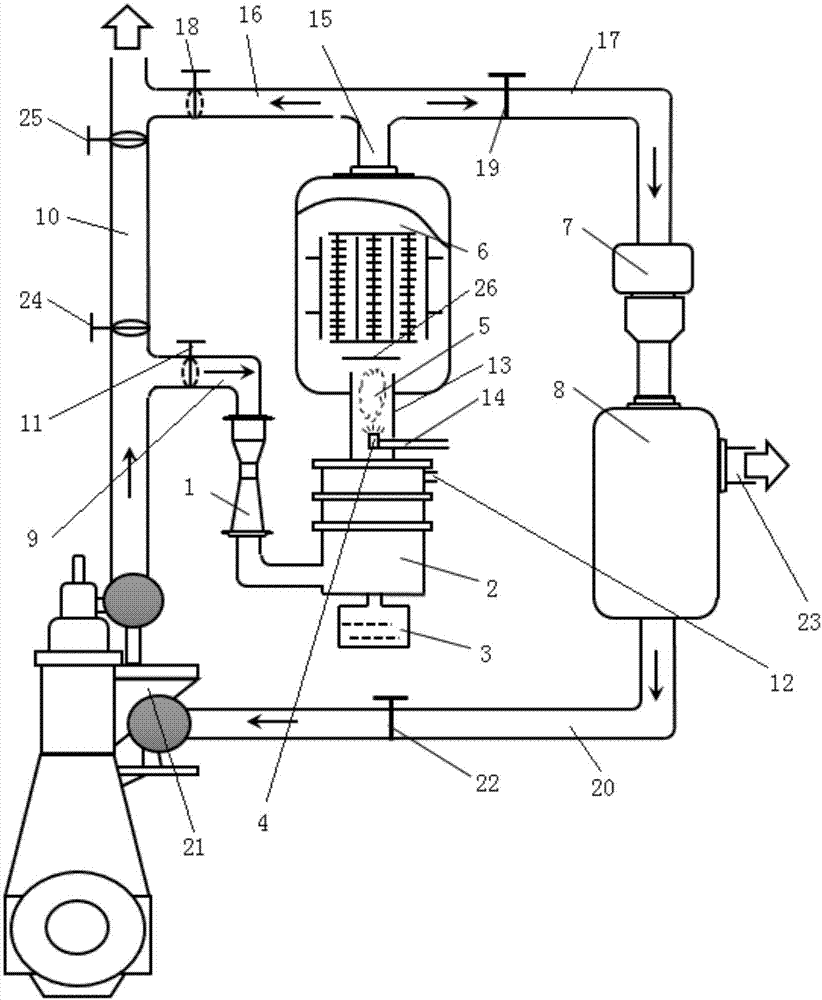

[0051] like figure 1 As shown, a comprehensive treatment device for marine diesel engine exhaust gas pollutants, including a Venturi tube washing device 1, a supergravity reactor 2, a waste liquid tank 3, an oxidant aerosol generating device 4, an aerosol reaction zone 5, and an electrostatic demisting device 6. Air compressor 7 and waste gas storage tank 8;

[0052] The lower part of the side wall of the supergravity reactor 2 communicates with the hole I on the side wall of the diesel engine exhaust pipe 10 through the pipe I9, and the side wall of the diesel engine exhaust pipe 10 is also provided with a hole II, and the hole II is located at Between the hole I and the exhaust port of the diesel engine exhaust pipe 10, the pipe I9 is provided with the Venturi tube cleaning device 1, located between the hole I and the Venturi tube cleaning device 1 The pipe section of the pipe I9 is provided with a one-way valve I11, the upper part of the side wall of the supergravity r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com