Lanthanum-doped silver niobate lead-free anti-ferroelectric energy storage ceramic material and preparation method thereof

A ceramic material, silver niobate technology, applied in the field of functional ceramic materials, can solve the problems of low turning electric field and breakdown field strength, affecting energy storage performance, etc., achieve good application prospects, high energy storage performance, promote application and The effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The energy storage ceramic material is composed of: Ag 0.97 La 0.01 NbO 3 (x=0.01)

[0061] (1) repeat the preparation method of comparative example 1 by above-mentioned formula;

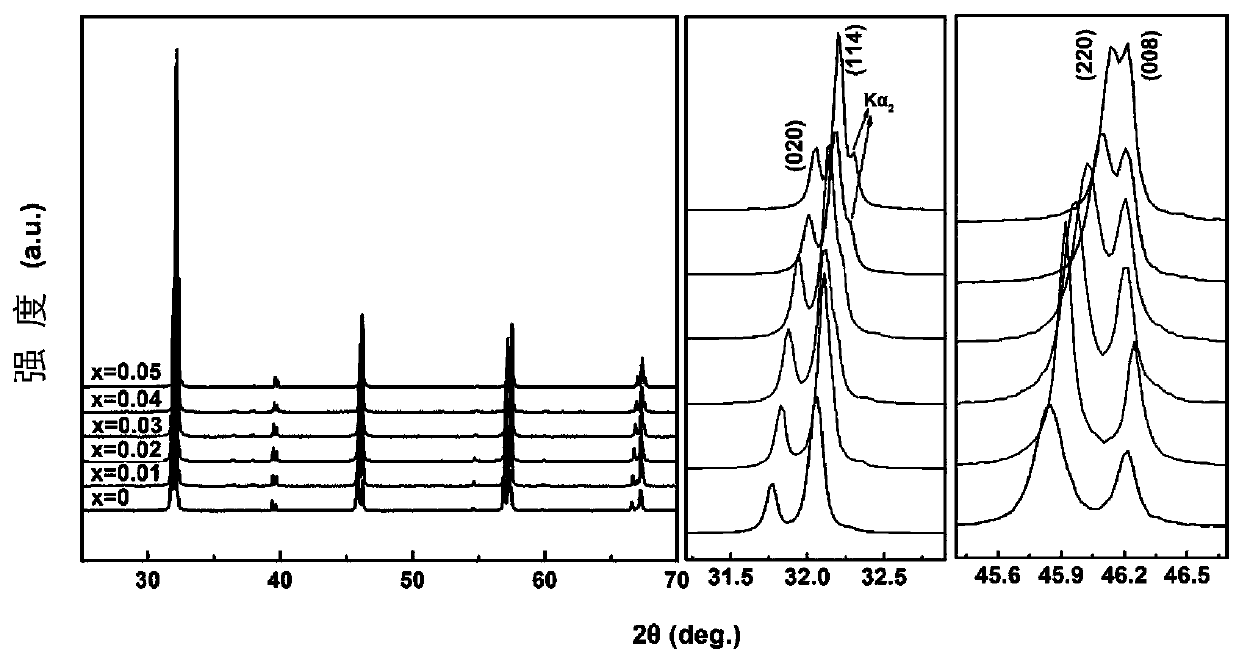

[0062] (2) Carry out XRD test to present embodiment, test result sees figure 1 ;

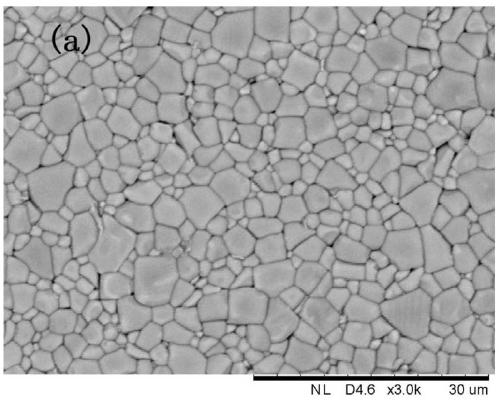

[0063] (3) carry out surface SEM test to present embodiment, image 3 The surface topography structure diagram of the ceramic sample of the present embodiment is provided;

[0064] (4) Calculate and plot the average grain size of the ceramic sample to obtain Figure 8 ;

[0065] (5) The ceramic samples were tested for dielectric thermogram and dielectric spectrum, and their phase transition temperature diagram was obtained. The test results are shown in Figure 9 ;

[0066] (6) Carry out the hysteresis loop measurement, the calculation of turning electric field and energy storage performance under room temperature to the ceramic sample of present embodiment, the result sees Figure 10-12 .

Embodiment 2

[0068] The energy storage ceramic material is composed of: Ag 0.94 La 0.02 NbO 3 (x=0.02)

[0069] (1) repeat the preparation method of comparative example 1 by above-mentioned formula;

[0070] (2) Carry out XRD test to present embodiment, test result sees figure 1 ;

[0071] (3) carry out surface SEM test to present embodiment, Figure 4 The surface topography structure diagram of the ceramic sample of the present embodiment is provided;

[0072] (4) Calculate and plot the average grain size of the ceramic sample to obtain Figure 8 ;

[0073] (5) The ceramic samples were tested for dielectric thermogram and dielectric spectrum, and their phase transition temperature diagram was obtained. The test results are shown in Figure 9 ;

[0074] (6) Carry out the hysteresis loop measurement, the calculation of turning electric field and energy storage performance under room temperature to the ceramic sample of present embodiment, the result sees Figure 10-12 .

Embodiment 3

[0076] The energy storage ceramic material is composed of: Ag 0.91 La 0.03 NbO 3 (x=0.03)

[0077] (1) repeat the preparation method of comparative example 1 by above-mentioned formula;

[0078] (2) Carry out XRD test to present embodiment, test result sees figure 1 ;

[0079] (3) carry out surface SEM test to present embodiment, Figure 5 The surface topography structure diagram of the ceramic sample of the present embodiment is provided;

[0080] (4) Calculate and plot the average grain size of the ceramic sample to obtain Figure 8 ;

[0081] (5) The ceramic samples were tested for dielectric thermogram and dielectric spectrum, and their phase transition temperature diagram was obtained. The test results are shown in Figure 9 ;

[0082] (6) Carry out the hysteresis loop measurement, the calculation of turning electric field and energy storage performance under room temperature to the ceramic sample of present embodiment, the result sees Figure 10-12 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com