Process for preparing xanthones under a catalyst-free condition

A technology of xanthone and a process method is applied in the field of preparation of chemical raw materials, can solve problems such as environmental pollution, increase production cost and the like, and achieve the effects of reducing production cost, reducing production cost and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] As a further optimization of the preparation method of xanthone in the present invention: the organic solvent is n-hexane, n-heptane, n-octane or cyclohexane.

[0021] As a further optimization of the preparation method of xanthone in the present invention: the amount of oxygen introduced is such that the pressure of oxygen in the reactor is 0.5-3 MPa.

[0022] As a further optimization of the preparation method of a xanthone of the present invention: the temperature during the reaction is 140-160°C.

[0023] As a further optimization of the preparation method of a xanthone of the present invention: the reaction time is 15-40h.

Embodiment 1

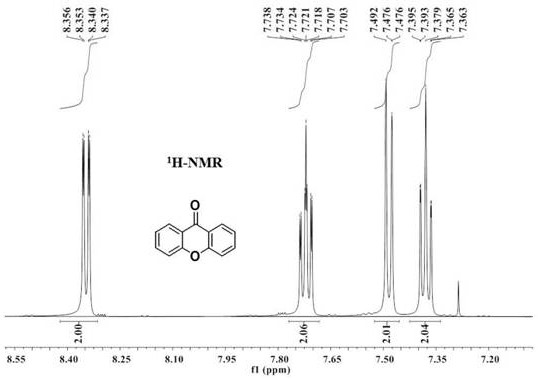

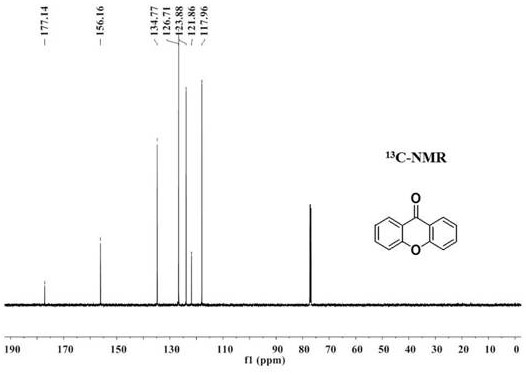

[0025] Take 2 mL of cyclohexane, 0.5 mmol of xanthene, and magnetons into a high-pressure reactor with a polytetrafluoroethylene liner, and then pass oxygen into the reactor until the pressure of oxygen in the reactor is 0.5 MPa , Then, seal the reaction kettle, put it into a heating tank with a temperature of 140° C., and carry out the reaction under magnetic stirring conditions for 20 h. After the reaction was completed, it was naturally cooled to room temperature. Afterwards, the internal standard quantitative analysis of the obtained product was carried out by using a gas chromatograph, and the yield of the xanthone product was measured to be 81%. Afterwards, the product is separated and purified by column chromatography to obtain the finished product of xanthone. use 1 H-NMR, 13 C-NMR confirms the structure of the product in the appendix figure 1 And attached figure 2 .

Embodiment 2

[0027] Take 2 mL of n-hexane, 0.5 mmol of xanthene, and magnetons into a high-pressure reactor with a polytetrafluoroethylene liner, and then pass oxygen into the reactor until the pressure of oxygen in the reactor is 0.5 MPa. Then, the reaction kettle was sealed and put into a heating tank with a temperature of 140° C., and reacted for 20 h under magnetic stirring conditions. After the reaction was completed, it was naturally cooled to room temperature, and then, the internal standard quantitative analysis of the obtained product was carried out by using a gas chromatograph, and the yield of the xanthone product was measured to be 73%. Afterwards, the product is separated and purified by column chromatography to obtain the finished product of xanthone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com