Poly(2-aminothiazole)/graphene-epoxy composite paint, and preparation method and applications thereof

A technology of aminothiazole and composite coatings, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as poor dispersion, corrosive medium shielding effect, and accelerated water molecule diffusion rate, so as to improve lubrication and anti-wear performance , reduce agglomeration, and improve the penetration performance of corrosion-resistant media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The poly(2-aminothiazole) / graphene-epoxy composite coating was quickly coated on the surface of the Q235 steel block, and dried at room temperature for 24 hours to obtain a poly(2-aminothiazole)-modified graphene-epoxy coating ,Specific steps are as follows:

[0047] (1) Using benzoyl peroxide and 1,4-dioxane as initiators, and 2-aminothiazole as polymerization monomers, uniformly mixing the initiators, monomers, solvents and catalysts to obtain by in-situ polymerization Poly(2-aminothiazole); The catalyst used therein is a catalyst known to those skilled in the art, which can be obtained commercially;

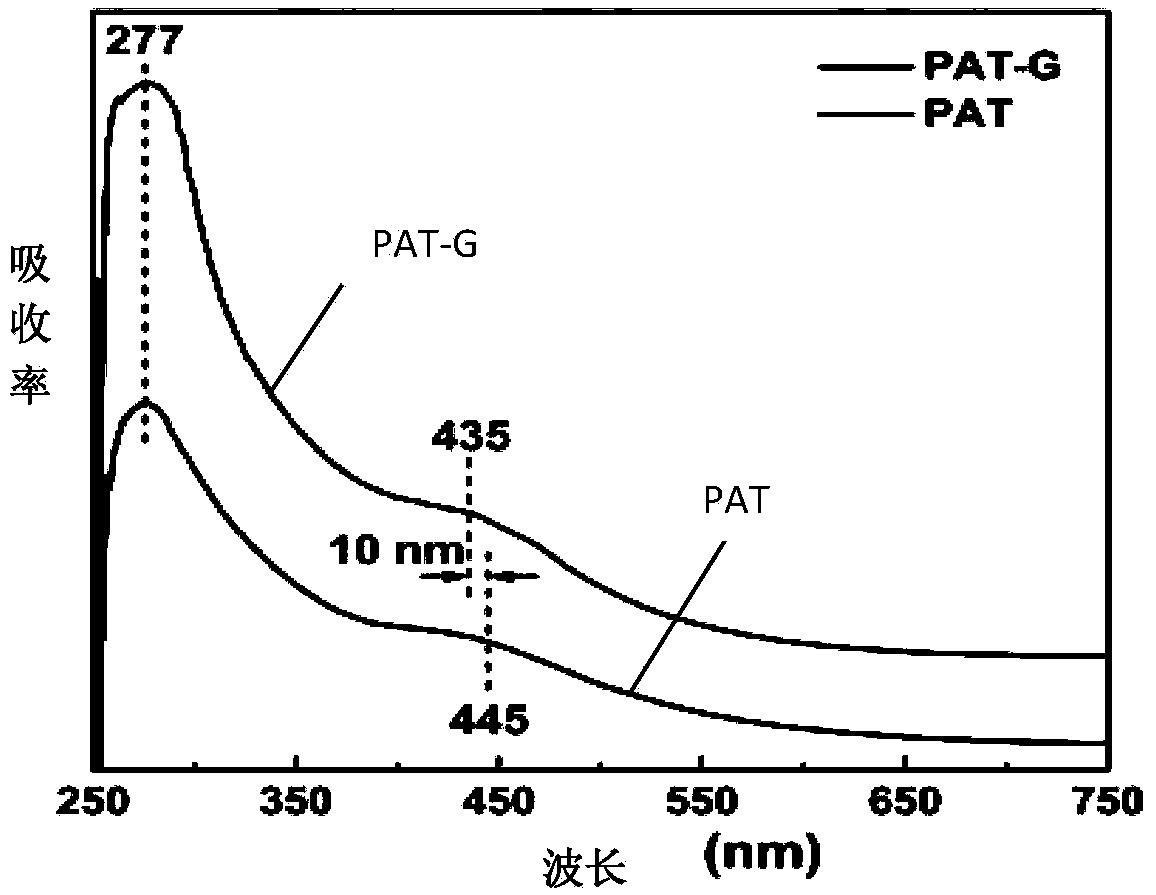

[0048] (2) Mixing and dispersing poly(2-aminothiazole) and graphene with a mass ratio of 1:4 in an organic solvent by physical ultrasonic vibration method, and exfoliating graphene to obtain poly(2-aminothiazole)-modified graphene Filler; the obtained poly(2-aminothiazole) modified graphene filler, organic solvent and epoxy resin are uniformly mixed under the condition...

Embodiment 2

[0059] The poly(2-aminothiazole) / graphene-epoxy composite coating was quickly coated on the surface of the Q235 steel block, and dried at room temperature for 24 hours to obtain a poly(2-aminothiazole)-modified graphene-epoxy coating ,Specific steps are as follows:

[0060] (1) Using benzoyl peroxide and 1,4-dioxane as initiators, and 2-aminothiazole as polymerization monomers, uniformly mixing the initiators, monomers, solvents and catalysts to obtain by in-situ polymerization Poly(2-aminothiazole); The catalyst used therein is a catalyst known to those skilled in the art, which can be obtained commercially;

[0061] (2) Mixing and dispersing poly(2-aminothiazole) and graphene with a mass ratio of 1.5:6 in an organic solvent by physical ultrasonic vibration method, and exfoliating graphene to obtain poly(2-aminothiazole)-modified graphene Filler; the poly(2-aminothiazole) modified graphene filler, organic solvent and epoxy resin are uniformly mixed at 25°C to obtain poly(2-a...

Embodiment 3

[0070] The poly(2-aminothiazole) / graphene-epoxy composite coating was quickly coated on the surface of the Q235 steel block, and dried at room temperature for 24 hours to obtain a poly(2-aminothiazole)-modified graphene-epoxy coating ,Specific steps are as follows:

[0071] (1) Using benzoyl peroxide and 1,4-dioxane as initiators, and 2-aminothiazole as polymerization monomers, uniformly mixing the initiators, monomers, solvents and catalysts to obtain by in-situ polymerization Poly(2-aminothiazole); The catalyst used therein is a catalyst known to those skilled in the art, which can be obtained commercially;

[0072] (2) Mixing and dispersing poly(2-aminothiazole) and graphene with a mass ratio of 1:6 in an organic solvent by physical ultrasonic vibration method, and exfoliating graphene to obtain poly(2-aminothiazole)-modified graphene Filler; the poly(2-aminothiazole) modified graphene filler, organic solvent and epoxy resin are uniformly mixed at 35°C to obtain poly(2-ami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com