Water base glass cutting fluid

A cutting fluid and glass technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of reduced glass strength, difficult cutting and processing of strengthened glass, easy to produce edge chipping, etc., and achieves good rust resistance and corrosion resistance, Improve processing efficiency and surface finish, good self-sharpening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

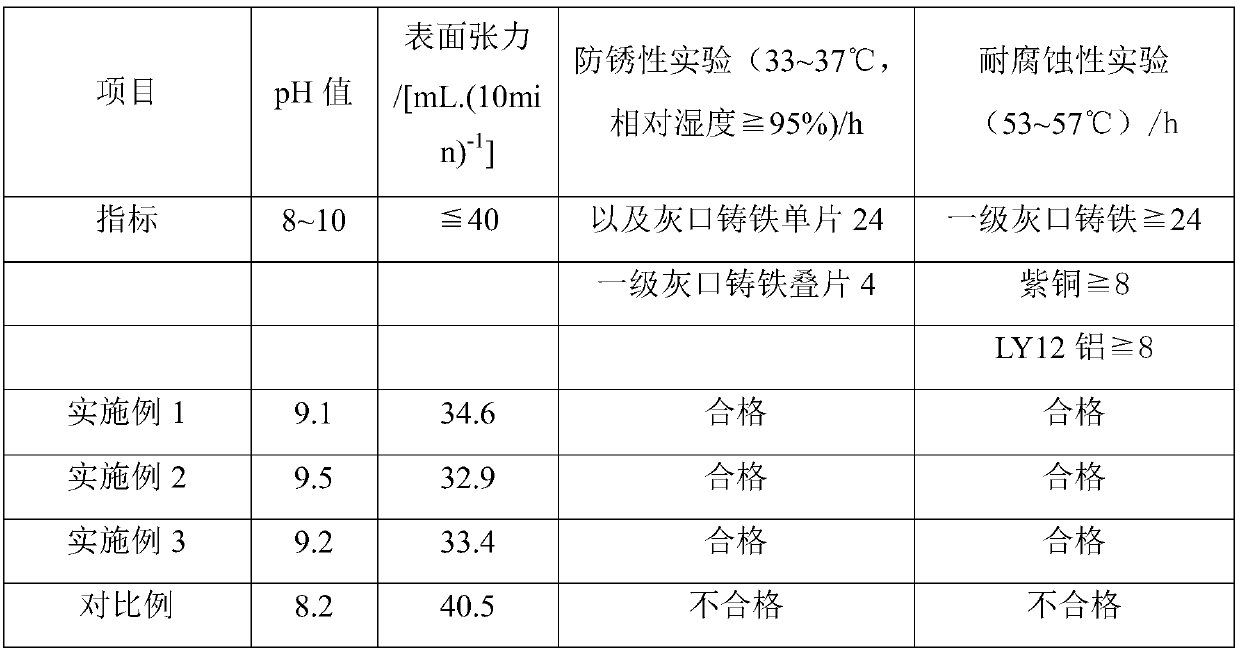

Examples

Embodiment 1

[0023] The water-based glass cutting fluid provided in this embodiment includes the following components by mass percentage: triethanolamine borate 8%, triethanolamine 12%; sodium dodecylbenzenesulfonate 6%; fatty alcohol polyoxyethylene 6% ether; 3% EDTA; 15% propylene glycol; 0.2% silicone defoamer, 49.8% deionized water.

Embodiment 2

[0025] The water-based glass cutting fluid provided in this embodiment includes the following components by mass percentage: 10% of sorbitol monooleate, 12% of triethanolamine; 8% of sodium dodecylbenzenesulfonate; fatty alcohol polymer Oxyethylene ether 6%; ethylenediamine succinic acid 3%; propylene glycol 15%; silicone defoamer 0.2%, deionized water 45.8%.

Embodiment 3

[0027] The water-based glass cutting fluid provided in this embodiment includes the following components by mass percentage: triethanolamine borate 10%, triethanolamine 12%; sodium dodecylbenzenesulfonate 6%; fatty alcohol polyoxyethylene 8% ether; 3% EDTA; 18% propylene glycol; 0.2% silicone defoamer, 42.8% deionized water.

[0028] In the above embodiment, the components are directly mixed and stirred to obtain the water-based glass cutting fluid.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap