Bearing life test and control software system based on LabVIEW

A software system, bearing life technology, applied in general control systems, mechanical bearing testing, control/adjustment systems, etc., can solve problems such as low accuracy of bearing life test results, improve flexibility and scalability, and facilitate comprehensive The effect of mastering and improving operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

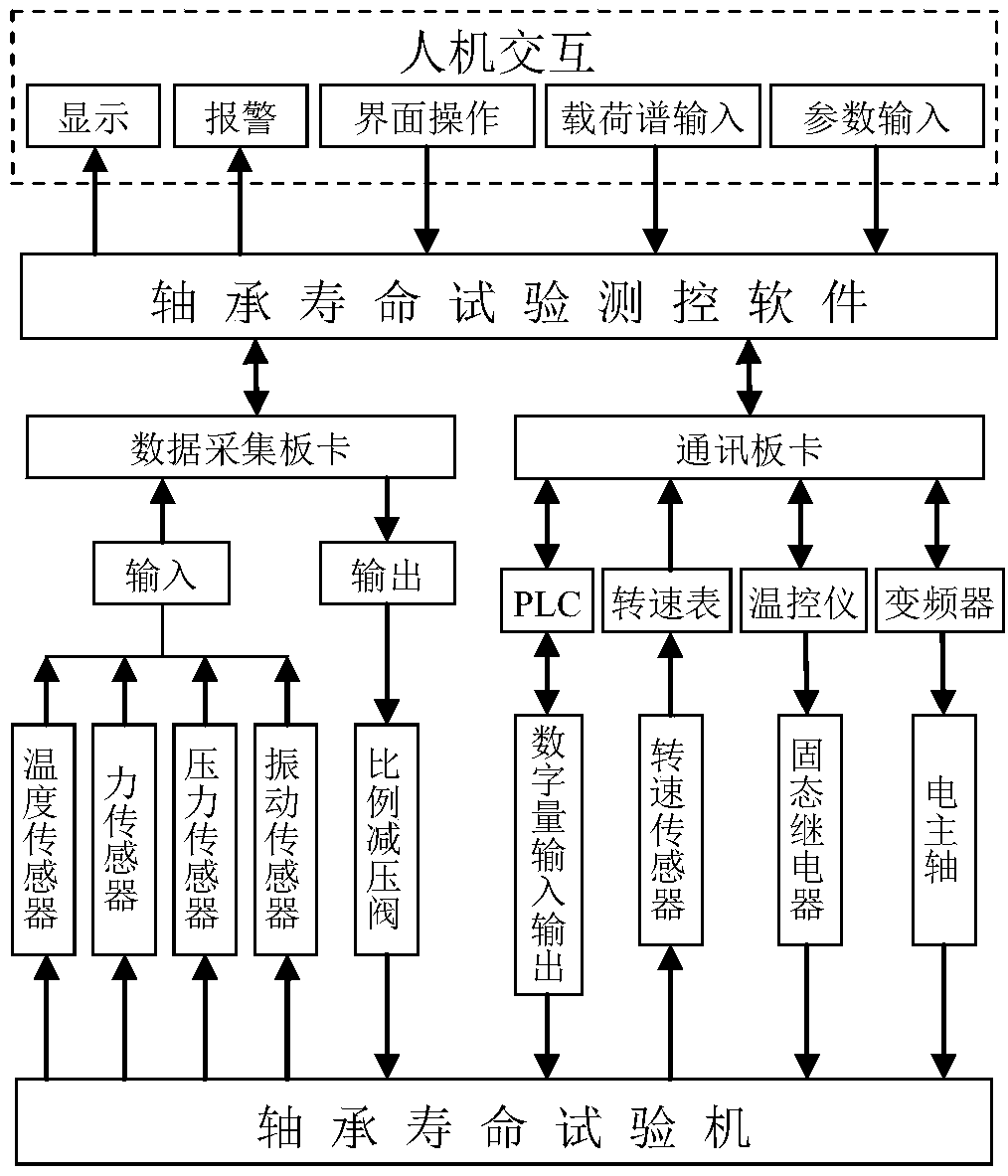

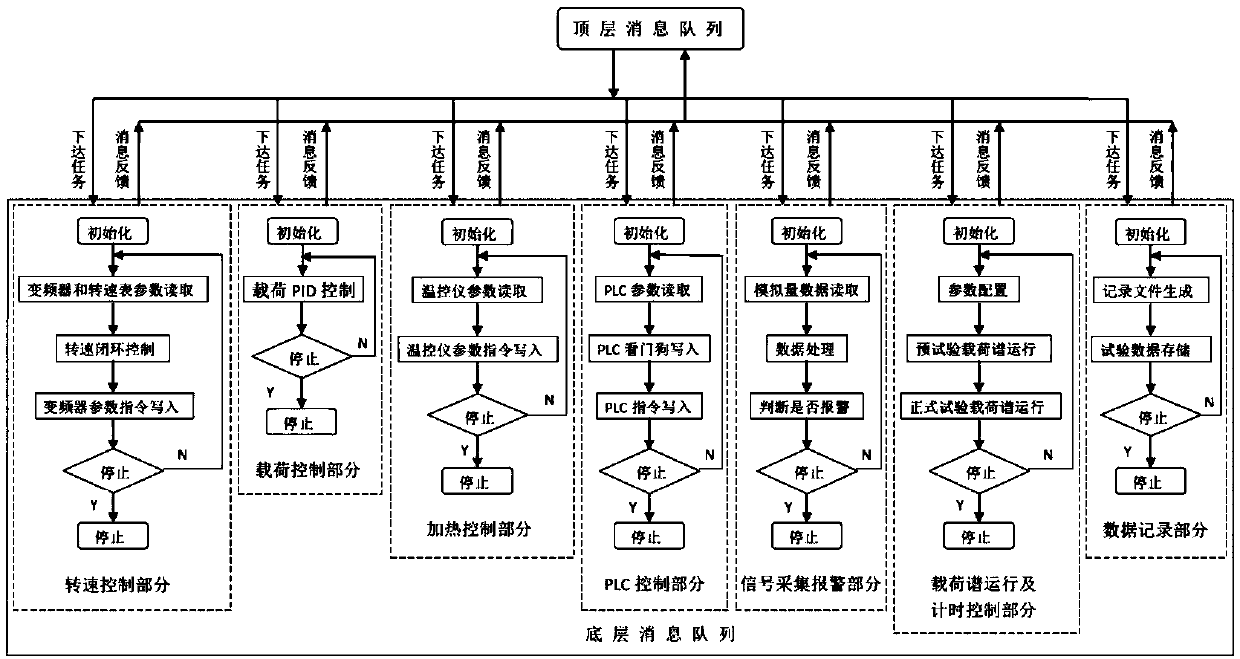

[0017] Such as figure 1 As shown, the hardware structure of the measurement and control system of the present invention includes hardware such as a bearing life tester, a sensor, a temperature controller, a frequency converter, and a communication board, and also includes a human-computer interaction interface, and each hardware part is realized by a measurement and control software system based on LabVIEW. Testing of bearing life. The LabVIEW-based bearing life test measurement and control software system of the present invention includes a top-level message queue and a bottom-level message queue. As the core control unit of the entire measurement and control software, the top-level message queue is not only used for the event response generated by the corresponding software interface, but also used for triggering Other underlying message queues...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com