phase boundary area regulation and control model modeling method under an MIHA pure pneumatic operation condition

A technology with purely pneumatic conditions and operating conditions, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of difficult removal of sulfur and limited desulfurization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] S100. Analyze the bubble generation process under pure aerodynamic conditions, and establish an energy conversion model in the bubble breaker;

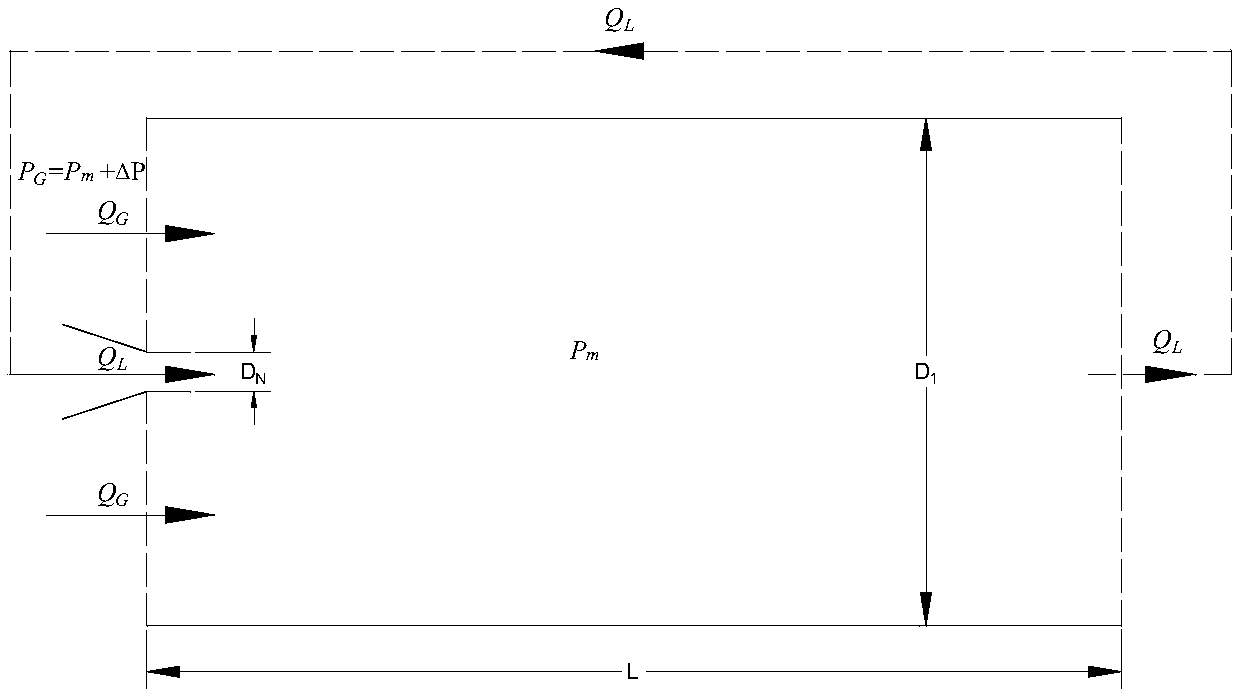

[0090] Before the gas is introduced, the bubble breaker is filled with static reaction solution. When the gas starts to flow in, due to the gas pressure P G and system operating pressure P m There is a pressure difference ΔP between them, the static pressure energy of the gas will be transferred to the liquid, and the liquid will be turbulent, and the pressure of the gas itself will be rapidly reduced to the operating pressure in the MIHA. Due to the flow of the gas-liquid two-phase, the gas-liquid flows out from the bubble breaker. For pneumatic operating conditions, the liquid flow Q L Much smaller than gas flow Q G , the energy required for the operation of the system is almost entirely provided by the gas pressure energy.

[0091] established as figure 1 A simplified diagram of the physical model is shown:

[0092] A...

Embodiment 2

[0165] This example specifically illustrates the phase boundary area control model constructed based on the method of Example 1.

[0166] Based on the modeling method of embodiment 1, the control model of phase boundary area is obtained as follows:

[0167]

[0168]

[0169]

[0170]

[0171] d max =0.75(σ L / ρ L ) 0.6 ε mix -0.4 (89)

[0172] d min =11.4(μ L / ρ L ) 0.75 ε mix -0.25 (90)

[0173]

[0174]

Embodiment 3

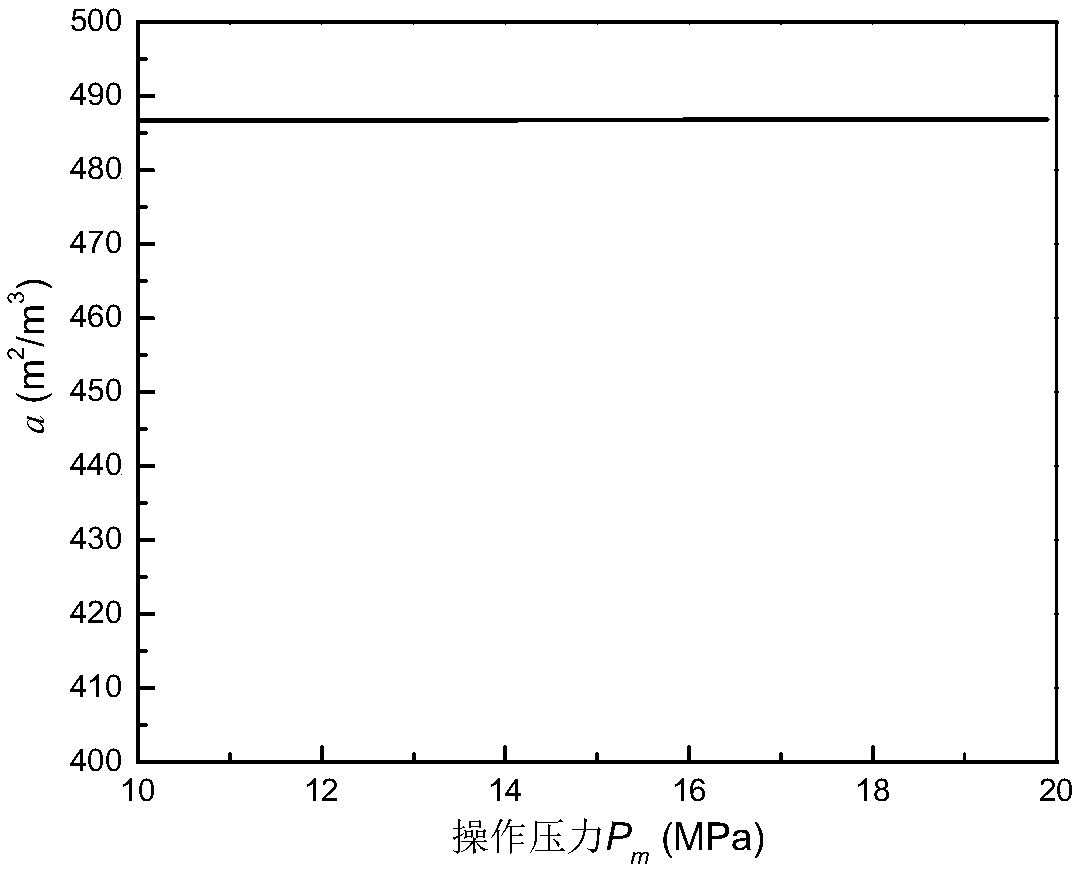

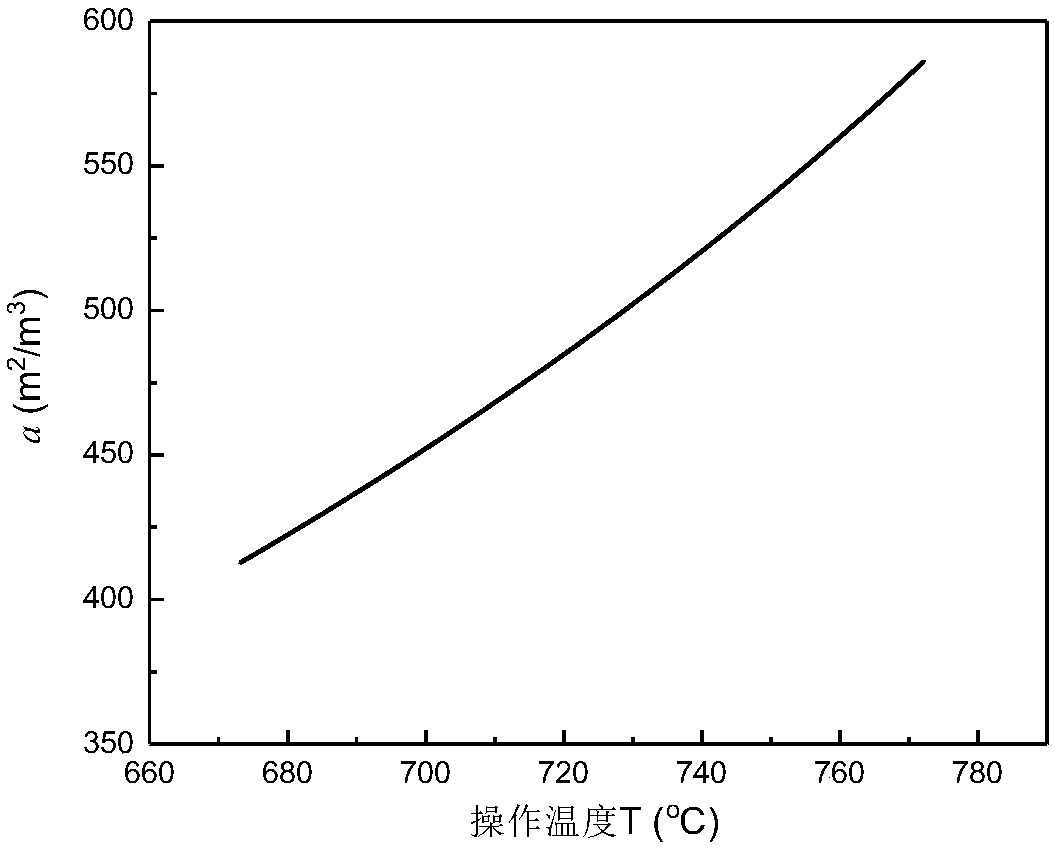

[0176] This example is based on the modeling method of Example 1, and studies the operating pressure, operating temperature, supply pressure difference ΔP and ventilation volume Q for the specific reactor structure and reaction system G Influence on the phase boundary area.

[0177] The general calculation conditions are as follows:

[0178] Crusher diameter D 1 =0.02m; The ratio of the diameter of the bubble breaker nozzle to the diameter of the breaker K 1 = 0.5;

[0179] Residue density ρ L =800Kg / m 3 ;

[0180] Residuum interfacial tension σ L The fitting formula is as follows:

[0181] σ L =[31.74-0.04775(T+273.15)]×10 -3 (N / m);

[0182] Kinetic viscosity of residual oil μ L The fitting formula is as follows;

[0183]

[0184] (1) The effect of operating pressure on the phase boundary area a;

[0185] The calculation conditions are as follows:

[0186] Ventilation Q G =80L / h; operating pressure P m =10~20MPa; supply pressure difference ΔP=6MPa; gas temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com