Modeling method for reaction rate and conversion rate regulation and control model under MIHA pure pneumatic operation condition

A technology of reaction rate and operating conditions, which is applied in the modeling field of reaction rate and conversion rate regulation model under MIHA pure pneumatic operating conditions, which can solve the problems of difficult removal of sulfur and limited desulfurization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051]It is generally believed that the basic structural unit of asphaltene is a fused aromatic ring system as the core and incorporates several naphthenic rings, with several alkyl side chains of different sizes on the aromatic ring and naphthenic ring, among which There are various heteroatom groups such as sulfur, oxygen, nitrogen, etc., and metals such as vanadium, nickel, and iron are complexed. The asphaltene molecule is composed of several (generally 4 to 6) structural units (or unit flakes) with the core of the fused aromatic ring system, and the structural units are generally separated by alkyl groups of different lengths. Bridges or sulfur bridges are connected. Microstructure studies have shown that asphaltene is usually a single particle of a semi-ordered graphite unit cell formed by stacking large molecular weight sheet-like condensed aromatic hydrocarbons, and also contains a small amount of metal porphyrin structure through π electrons The interaction of asphal...

Embodiment 2

[0195] This example specifically illustrates the reaction rate and conversion regulation model constructed based on the method in Example 1.

[0196] The modeling method based on embodiment 1 obtains reaction rate and conversion rate control model as follows:

[0197]

[0198]

[0199]

[0200]

[0201]

[0202] d e = d 32 (ρ L g / σ L ) 1 / 2 (15)

[0203] K b =K b0 m o -0.038 (16)

[0204] v G =4Q G / πD 0 2 (17)

[0205] v L =4Q L / πD 0 2 (18)

[0206]

[0207]

[0208]

[0209]

[0210]

[0211]

[0212]

[0213] d max =0.75(σ L / ρ L ) 0.6 ε mix -0.4 (51)

[0214] d min =11.4(μ L / ρ L ) 0.75 ε mix -0.25 (52)

[0215]

Embodiment 3

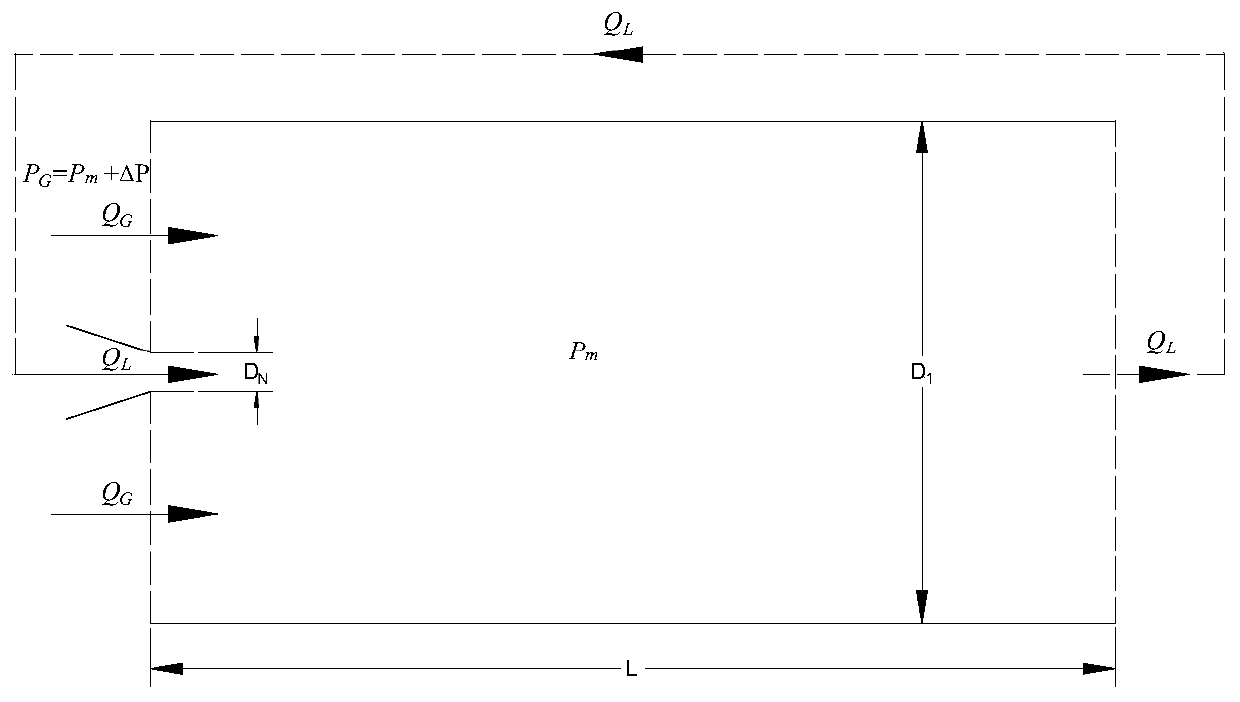

[0217] Based on the modeling method in Example 1, it can be known that for the asphaltene hydrogenation reaction in the MIRA under pure aerodynamic conditions, the factors that determine the final conversion rate of asphaltene include:

[0218] Reactor structure parameters: Crusher diameter D 1 , Reactor diameter D 0 , Nozzle to crusher diameter ratio K 1 , Reactor height H 0 ;

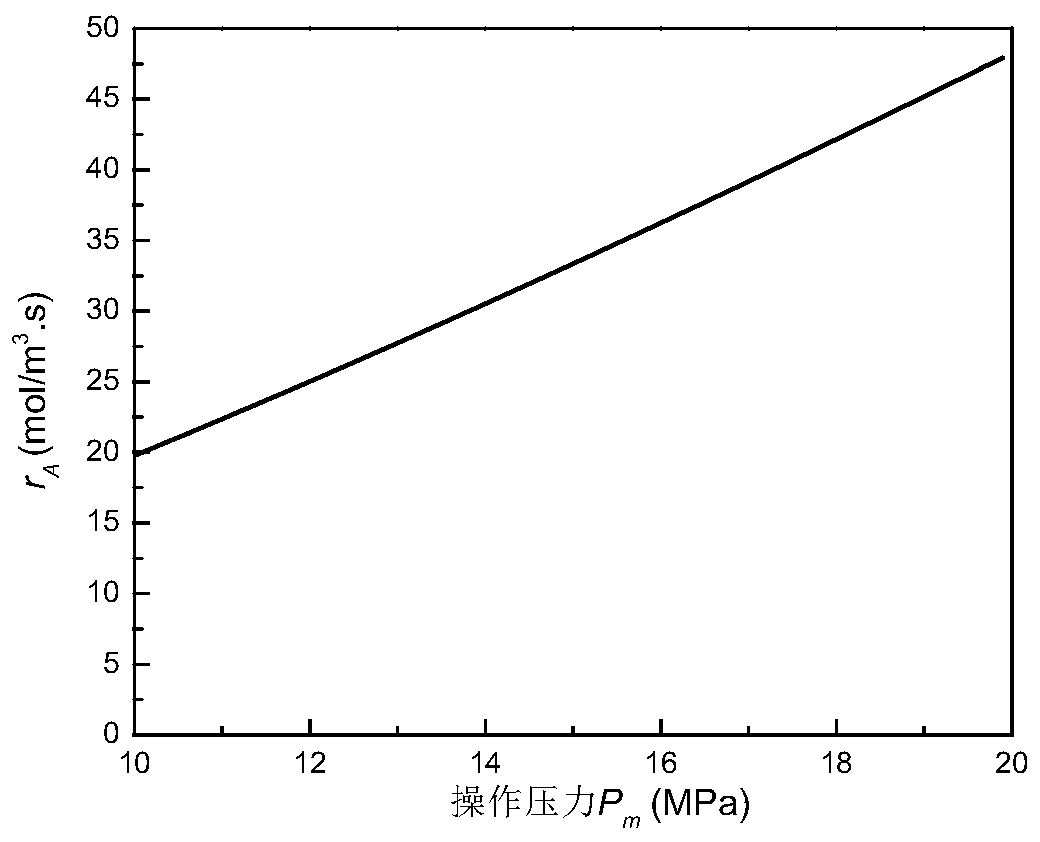

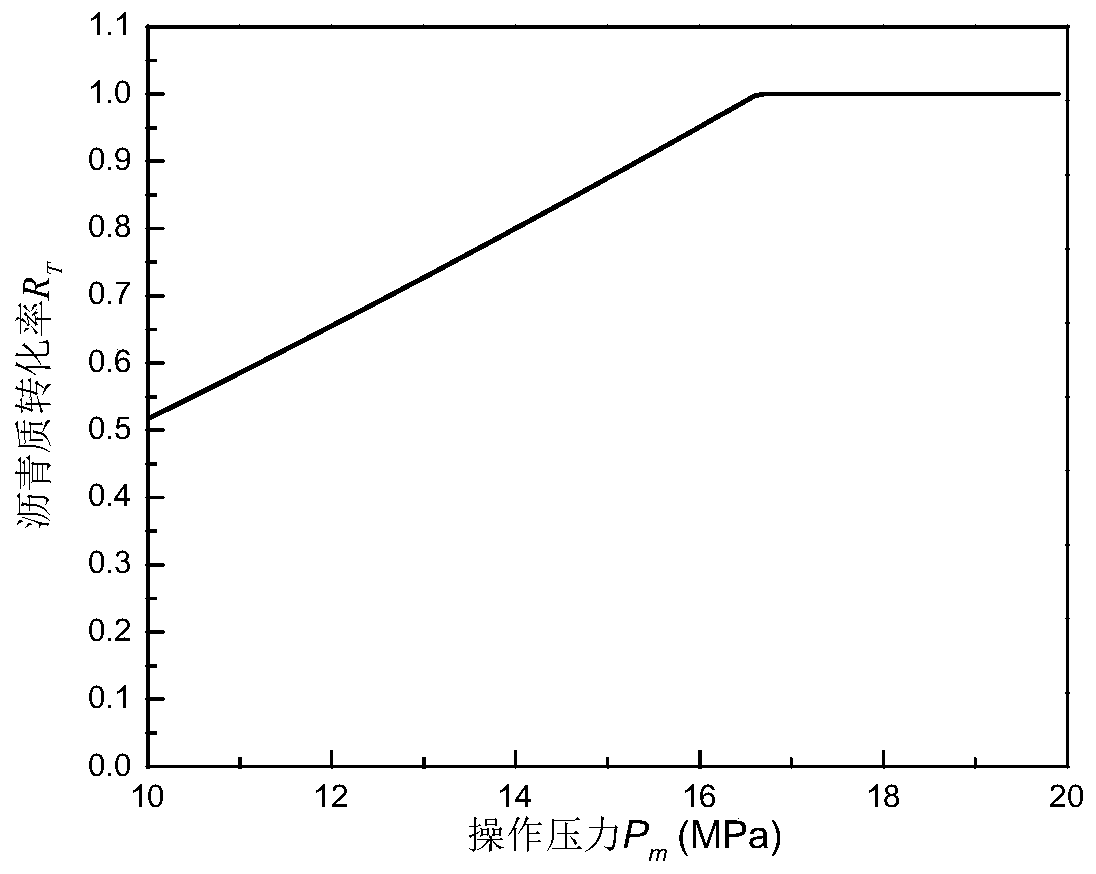

[0219] Operating parameters: operating pressure P m , operating temperature T, supply air flow Q G ;

[0220] Physical parameters: residual oil density ρ L , residual oil interfacial tension σ L , residual oil dynamic viscosity μ L ;

[0221] Energy parameters: supply pressure difference ΔP;

[0222]Intrinsic reaction rate: k A ;

[0223] In order to optimize the MIHA structure and actual operation, this example is based on the modeling method of Example 1, and studies the operating pressure, operating temperature, supply pressure difference ΔP and ventilation rate Q for the specific react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com