Highly reliable double-sided heterogeneous composite electrode chip capacitor

A technology of chip capacitors and composite electrodes, applied in the direction of fixed capacitor electrodes and components of fixed capacitors, etc., can solve the problems of sudden change in the electrical performance of the chip, no silver adhesion, and change in the performance of the chip electrode, so as to achieve good welding effect and prevent silver migration. , the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

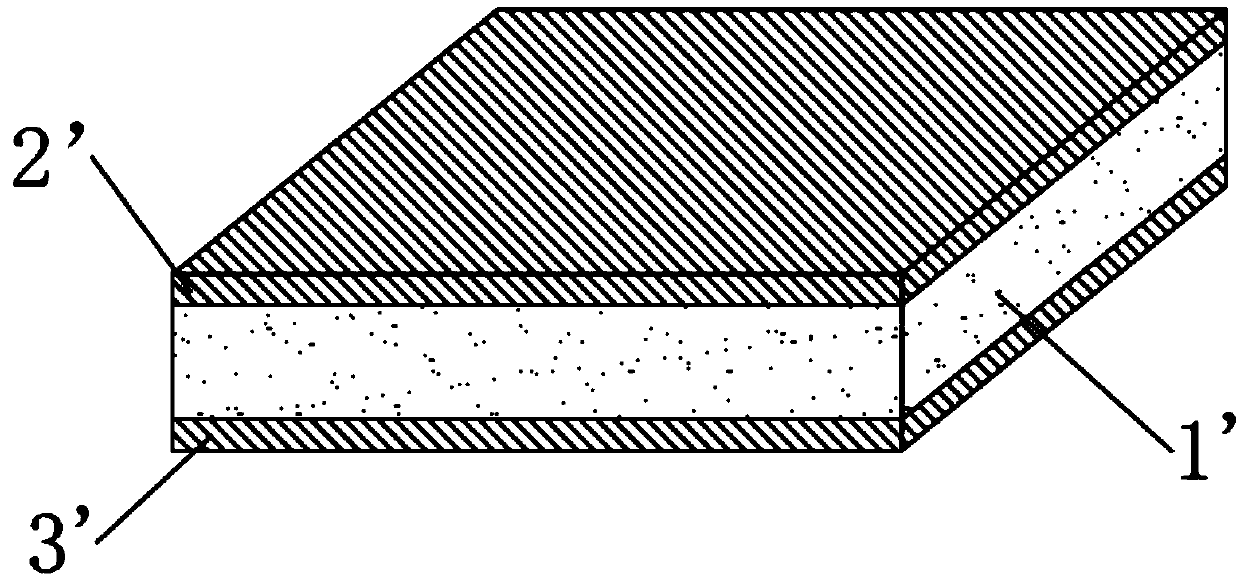

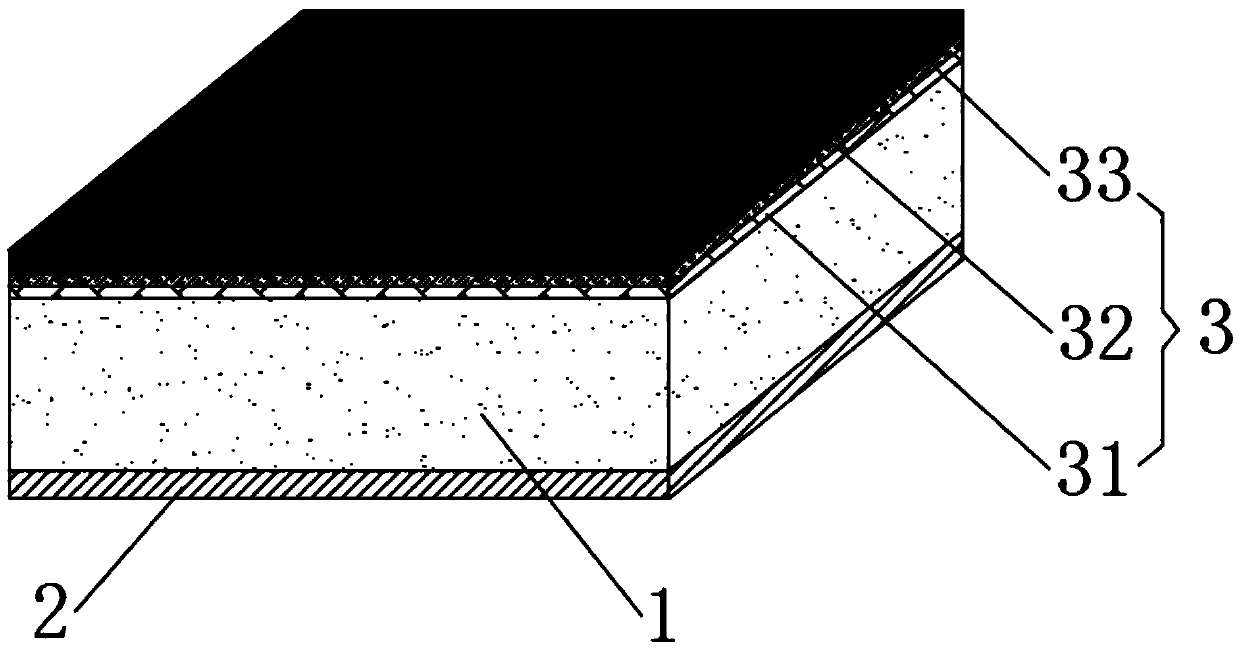

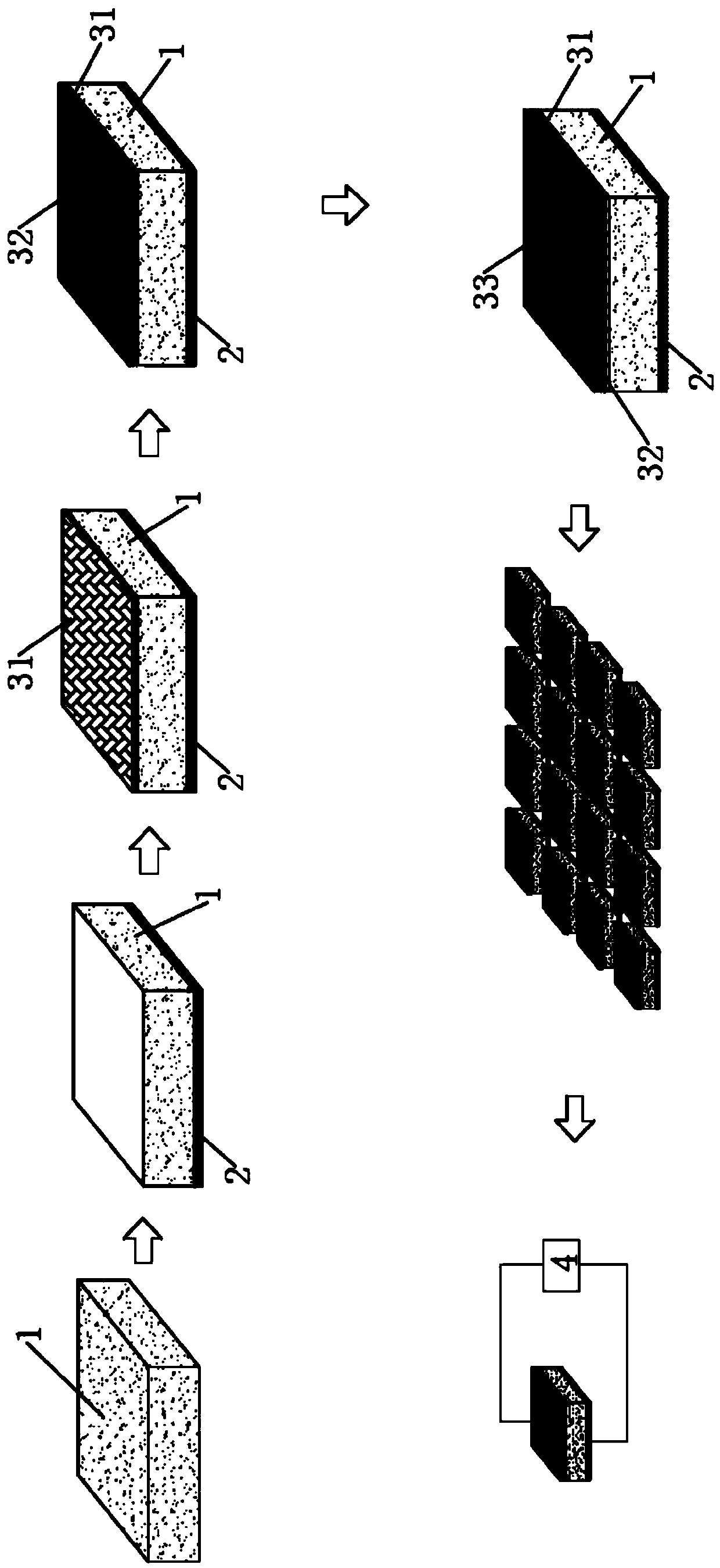

[0032] see figure 2 , which is a structural schematic diagram of the highly reliable double-sided heterogeneous composite electrode chip capacitor of the present invention;

[0033] The high-reliability double-sided heterogeneous composite electrode chip capacitor of the present invention includes a capacitor ceramic substrate 1, a surface electrode 2 and a bottom electrode 3, and the surface electrode 2 and the bottom electrode 3 are respectively arranged on both surfaces of the capacitor ceramic substrate 1 Above: the surface electrode 2 is a silver layer, and the bottom electrode 3 is formed by stacking a titanium-tungsten layer 31 , a copper layer 32 and a gold layer 33 sequentially on the capacitive ceramic substrate 1 from inside to outside.

[0034]Specifically, in the surface electrode 2, the thickness of the titanium-tungsten layer 31 is 0.1-0.15 microns, the thickness of the copper layer 32 is 0.1-0.2 microns, and the thickness of the gold layer 33 is 0.25-0.55 micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com