Method for low-voltage assistance in connection of nano silver solder paste with large-area substrate and heat dissipating device

A heat sink, nano-silver technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of organic residues, affecting the thermal conductivity and reliability of sintered substrates, and save sintering costs. , the effect of low elastic modulus and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

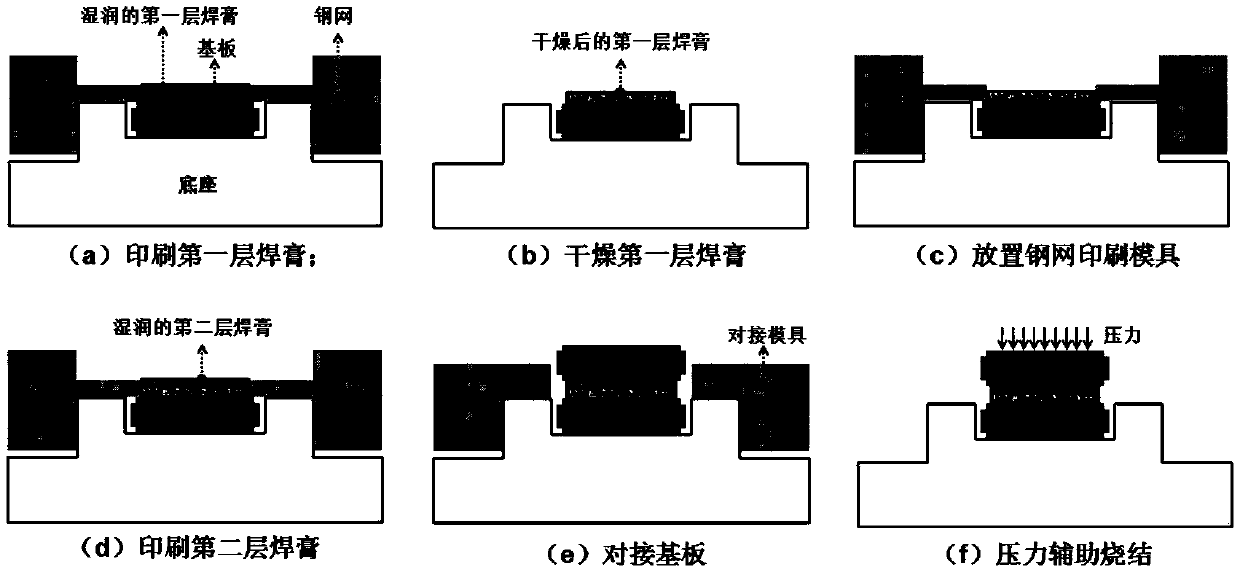

[0026] Such as figure 1 Shown is the manufacturing process of the method for connecting a large-area substrate and a heat sink with a low-pressure assisted nano-silver solder paste. Such as figure 2 Shown is the sintering process curve of the low-pressure assisted nano-silver solder paste connecting the large-area substrate and the heat sink. Combine below figure 1 and figure 2 The specific sintering process of low-voltage assisted nano-silver solder paste connecting large-area substrates and heat sinks is described in detail:

[0027] (1) The pretreatment process is as follows: 99.9% copper substrate is used, and the substrate area is greater than 800mm 2 , cut into 25.4mm*45.72mm*1mm, and electroplate a 10μm silver layer after cleaning; clean the silver-plated copper substrate in an ultrasonic cleaner for 10 minutes, and wipe it with a dust-free paper after cleaning;

[0028] (2) Put the cleaned substrate on the base of the mold, and fix the steel mesh matching the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com