Flexible manufacturing system

A flexible manufacturing system and six-axis robot technology, applied in manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve the problems of undiscovered patent documents, etc., to improve product quality, high yield rate, and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

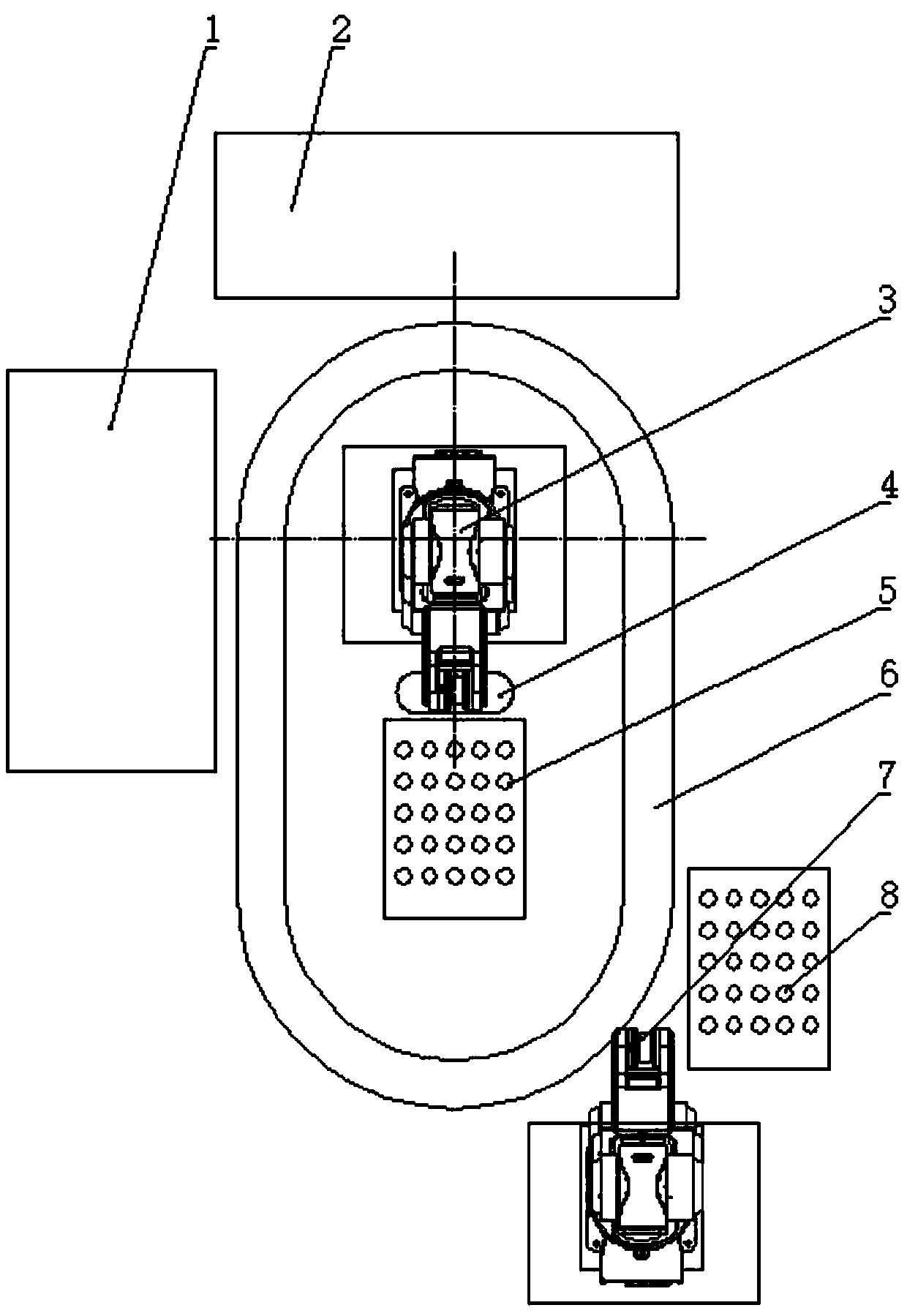

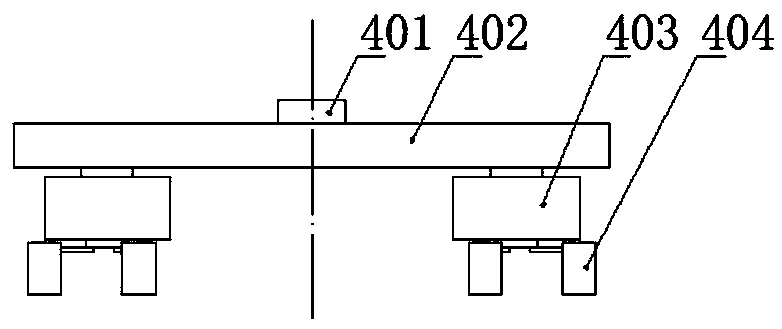

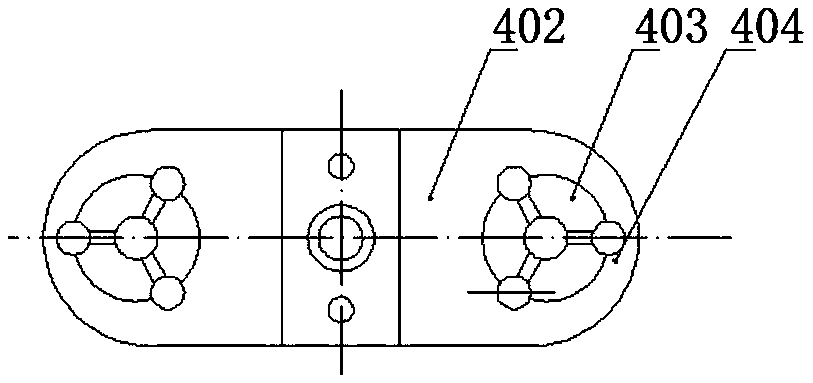

[0029] A flexible manufacturing system, including a six-axis robot 3, a conveyor belt 6, a palletizing pallet 5, a high-precision machining center 2, a turning machining center 1, a special fixture 4, a feeding manipulator 7, and a blank tray 8, and the manipulator of the six-axis robot A special fixture is installed at the end, and a circular conveyor belt is installed on the outer periphery of the six-axis robot. A palletizing tray is installed on the radial side of the six-axis robot on the inner ring of the conveyor belt. Precision machining centers and turning centers;

[0030] A blank tray 8 for containing blank material is installed on the periphery of the conveyor belt. A loading robot 7 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com