Gravity energy storage system of hoisting and transporting system based on mine vertical shaft

A technology of transportation system and energy storage system, applied to lifting equipment, transportation and packaging, elevators and other directions in mines, can solve the problems of low total efficiency, high maintenance cost, high system complexity, and achieve long-term energy storage without loss , High energy cycle efficiency, overcoming the effect of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

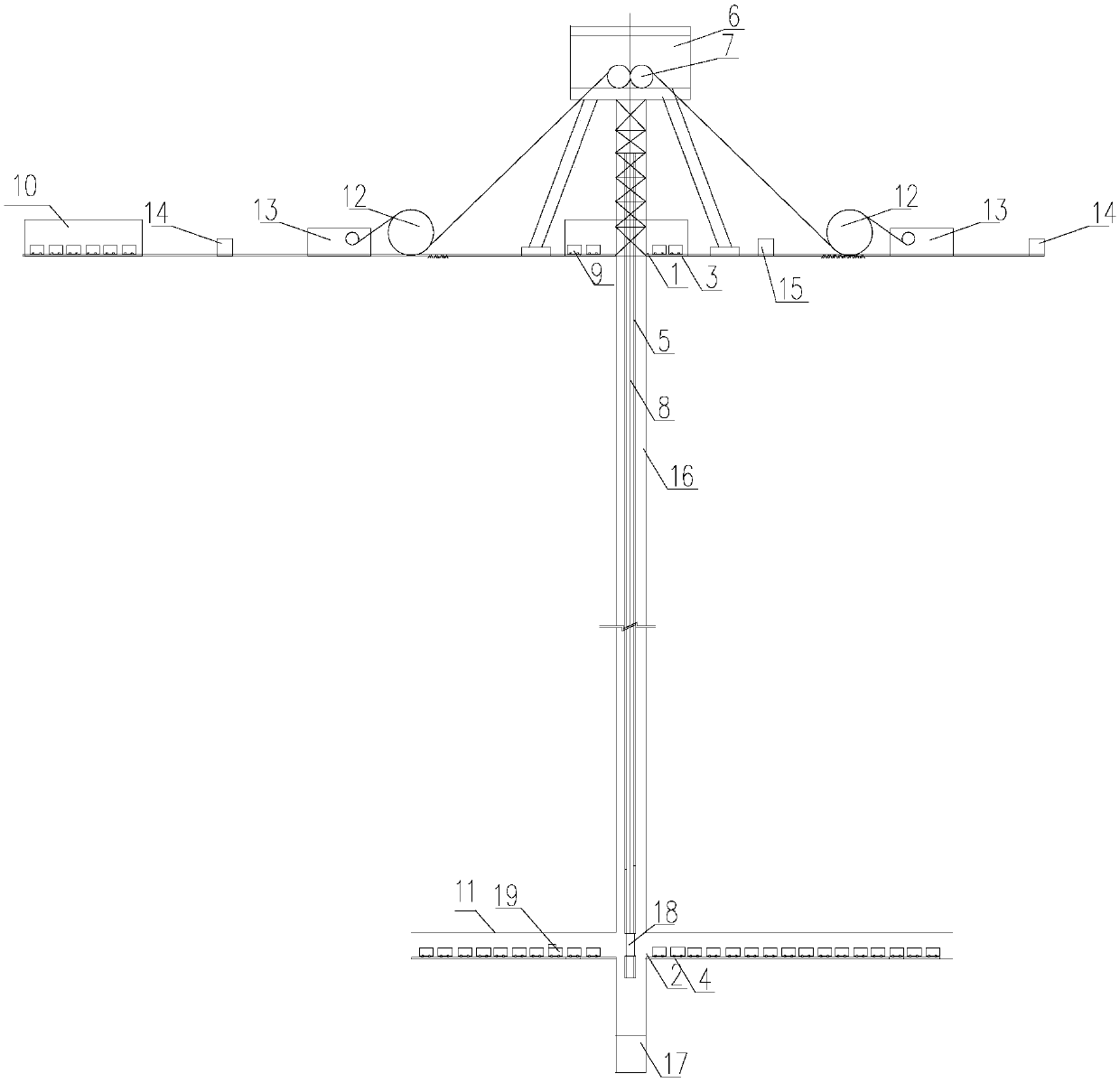

[0032] see figure 1 The gravitational energy storage system based on mine vertical shaft, lifting and transportation system provided by the present invention includes a wellhead platform 1, a bottom parking platform 2, a wellhead driving equipment 3, a bottom driving equipment 4, a shaft equipment tank road 5, Derrick 6, derrick top wheel 7, steel wire rope 8, equal-heavy mine car with counterweight (hereinafter referred to as mine car 9), machine repair garage workshop 10, bottom shaft yard and chamber 11, wire rope winch 12, electric generator integrated machine 13 and Control system 14, transformer 15, shaft 16, water 17, cage 18 and battery locomotive 19. The mine car 9 with the same counterweight is parked near the wellhead platform 1 and the well bottom parking platform 2. Utilize the wellbore equipment tank road 5 between them as the heavy object glide track, be provided with a set of electric generator integrated machine 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com