Foam material comprising esterification modified AC foaming agent and preparation method thereof

A technology of esterification modification and foaming materials, applied in organic chemistry, bulk chemical production, etc., to achieve the effects of lowering decomposition temperature, increasing gas production, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

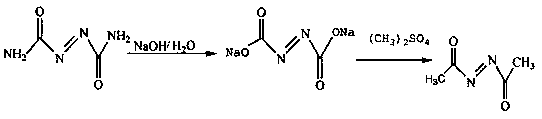

Method used

Image

Examples

Embodiment 1-3

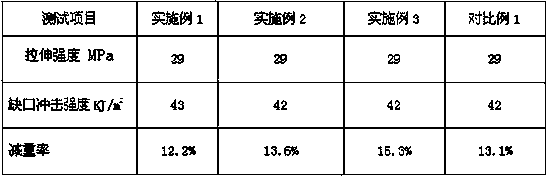

[0023] Examples 1-3, the weight distribution ratio of each component in each embodiment is shown in Table 1. Weigh each component according to the ratio, mix it in a high-speed mixer for 6-8 minutes, and discharge the material. Put the raw material of the mixture into the injection molding machine for injection. The temperature of the injection molding machine is controlled between 170-190 ° C to prepare the sample. Corresponding standard tests (see Table 2) and performance results are shown in Table 3.

[0024] Table 1: the formula composition (part) of embodiment 1-3

[0025]

[0026] Table 2: Mechanical property test standard

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com