A kind of 3D printing silk protein hydrogel and preparation method thereof

A 3D printing, silk protein technology, applied in the field of biomedical materials, can solve problems such as large steric hindrance effect, affecting the interaction of host and guest, affecting self-healing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

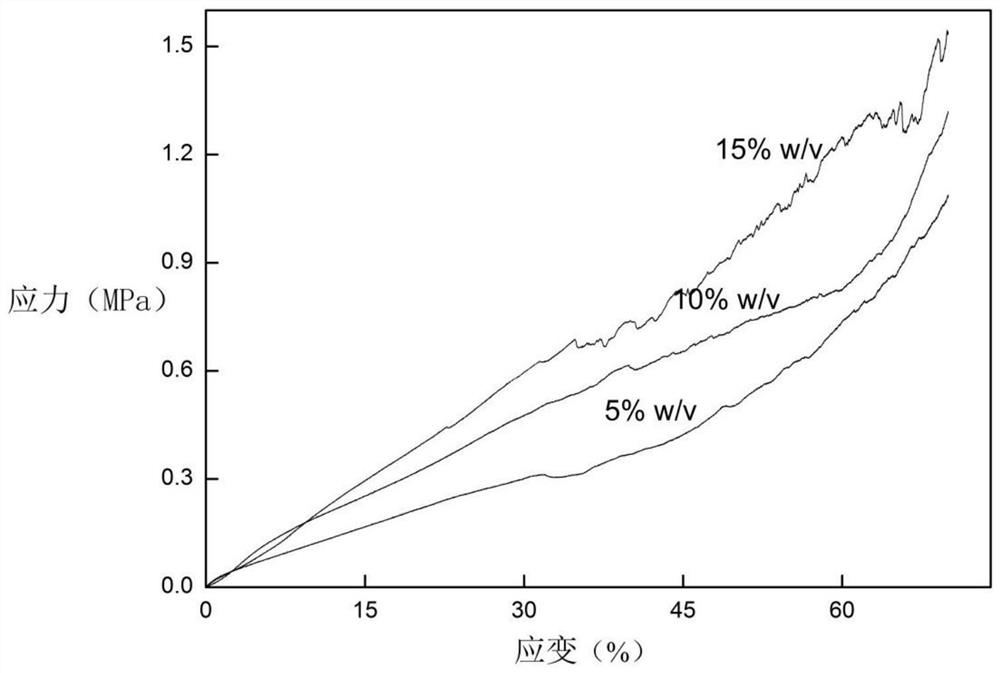

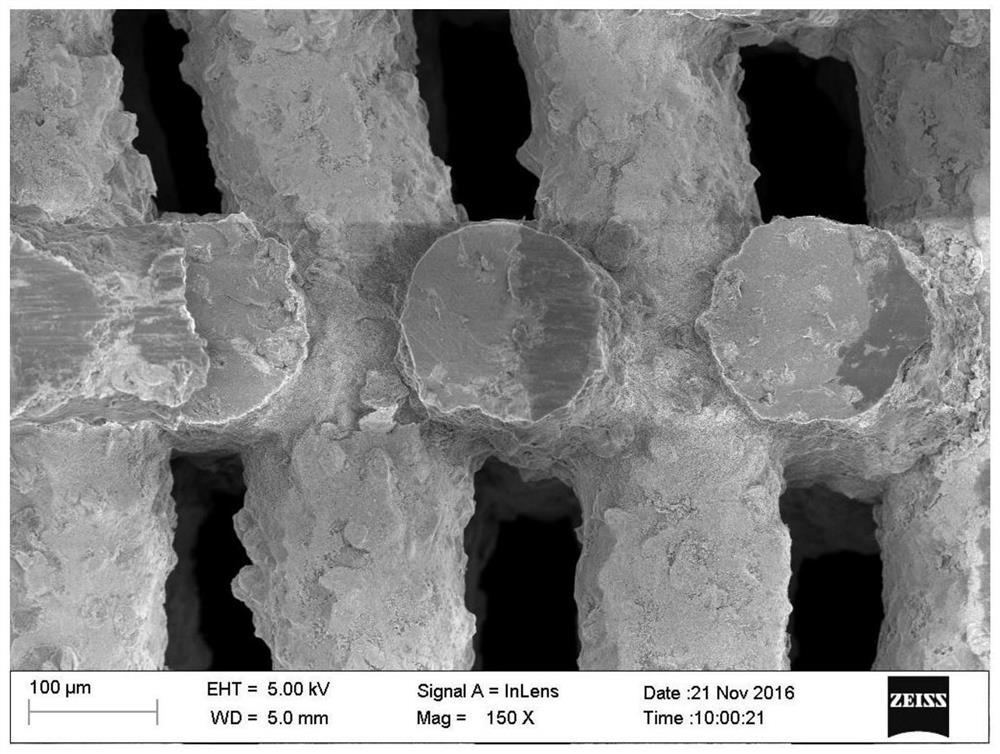

[0028] Get 1.5g silk protein and join in 30ml deionized water, use magnetic stirrer ( KW20) stirred for 3 hours to obtain a silk protein solution with a mass volume percent concentration of 5% (w / v), took 1 g of double bond modified cyclodextrin and added 10 ml of deionized water, fully stirred to form a cyclodextrin solution, and then the cyclodextrin Add the fine solution and I2959 photoinitiator into the silk protein solution, continue to stir for 1 hour to form a single-network cross-linked silk protein hydrogel, put the single-network cross-linked silk protein hydrogel into a 30cc printing cylinder, and then put Put the printing barrel into the ultraviolet light with an intensity of 10mw / cm 2 In the ultraviolet irradiation device, the double bonds on the cyclodextrin molecular chains are cross-linked by irradiation for 1 hour, forming a pre-crosslinked silk protein hydrogel.

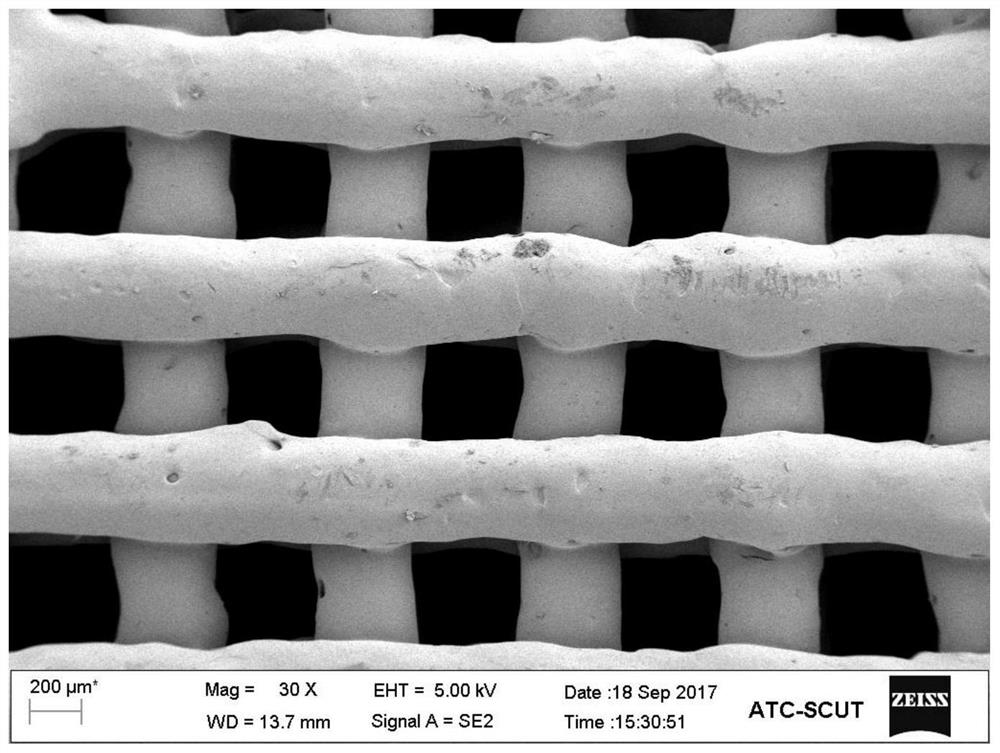

[0029] The silk protein hydrogel is selected as a cuboid structure, the size is 10mm×10mm×2mm,...

Embodiment 2

[0031] Get 3g silk protein and join in 30ml deionized water, use magnetic stirrer ( KW20) stirred for 3 hours to obtain a silk protein solution with a mass volume percentage concentration of 10% (w / v), added I2959 photoinitiator and 1 g of double bond-modified cyclodextrin to the silk protein solution, and continued to stir for 1 hour to form a single network. Linked silk protein hydrogel, the single-network cross-linked silk protein hydrogel is loaded into a 30cc printing cartridge, and then the printing cartridge is placed in a UV light with an intensity of 5mw / cm 2 In the ultraviolet irradiation device, the double bond on the cyclodextrin molecular chain is cross-linked by irradiation for 2 hours, and the pre-crosslinked silk protein hydrogel is formed.

[0032] The silk protein hydrogel is selected as a cuboid structure, the size is 10mm×10mm×2mm, and the printing height of each layer is 0.32mm. The extrusion pressure of the pre-crosslinked silk protein hydrogel is select...

Embodiment 3

[0034] Get 4.5g silk protein and join in 30ml deionized water, use magnetic stirrer ( KW20) stirred for 1 h to obtain a silk protein solution with a mass volume percentage concentration of 15% (w / v), added I2959 photoinitiator and 3 g of double bond-modified cyclodextrin to the silk protein solution, and continued to stir for 3 h to form a single network intersection Linked silk protein hydrogel, put the single network cross-linked silk protein hydrogel into a 30cc printing cartridge, and then put the printing cartridge into a UV light with an intensity of 10mw / cm 2 In the ultraviolet irradiation device, the double bonds on the cyclodextrin molecular chains are cross-linked by irradiation for 1 hour, forming a pre-crosslinked silk protein hydrogel.

[0035] The silk protein hydrogel is selected as a cuboid structure, the size is 10mm×10mm×2mm, and the printing height of each layer is 0.32mm. The extrusion pressure of the pre-crosslinked silk protein hydrogel is selected as 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com