Planetary pin roller lead screw with annular grain lead screw matched with threaded shaft sleeve

A planetary roller, threaded bushing technology, used in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problems of increased friction and impact, uneven operation, vibration and noise, etc., to achieve smooth operation, The effect of high transmission position accuracy and low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

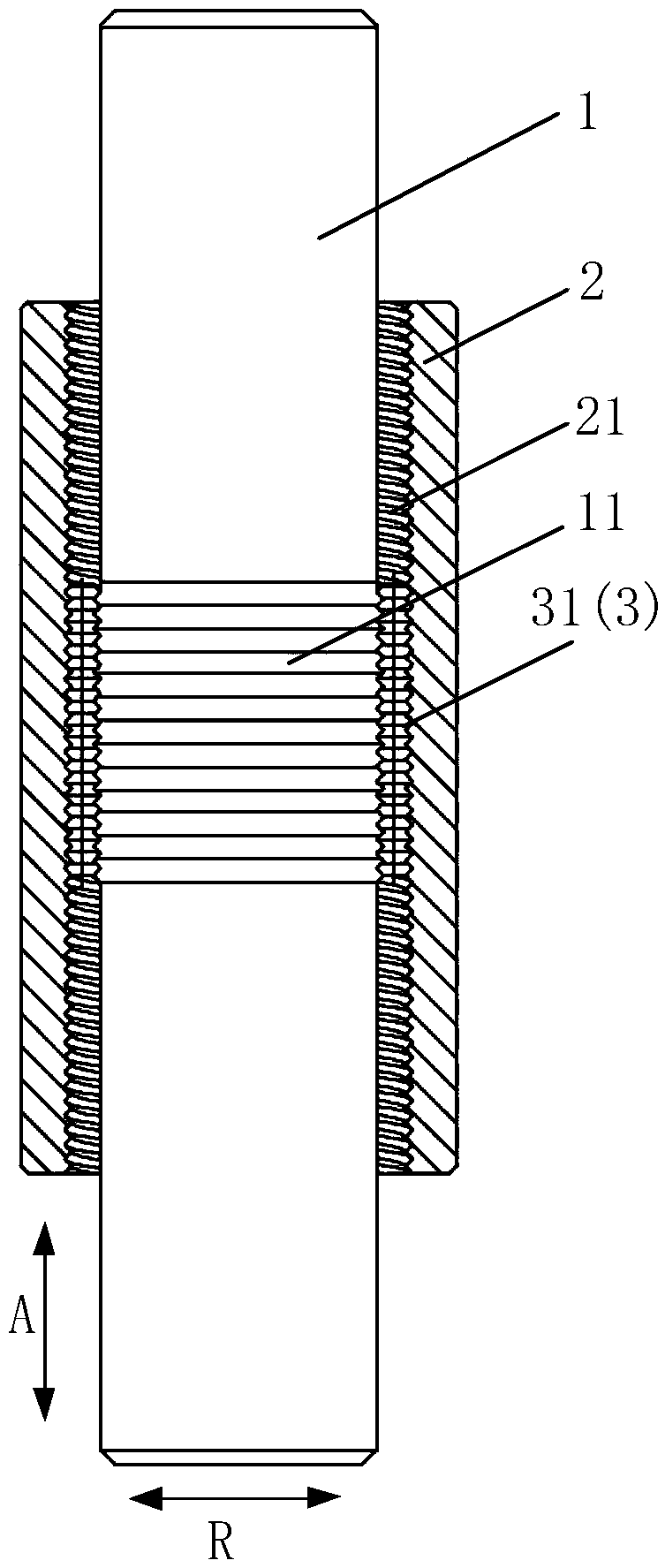

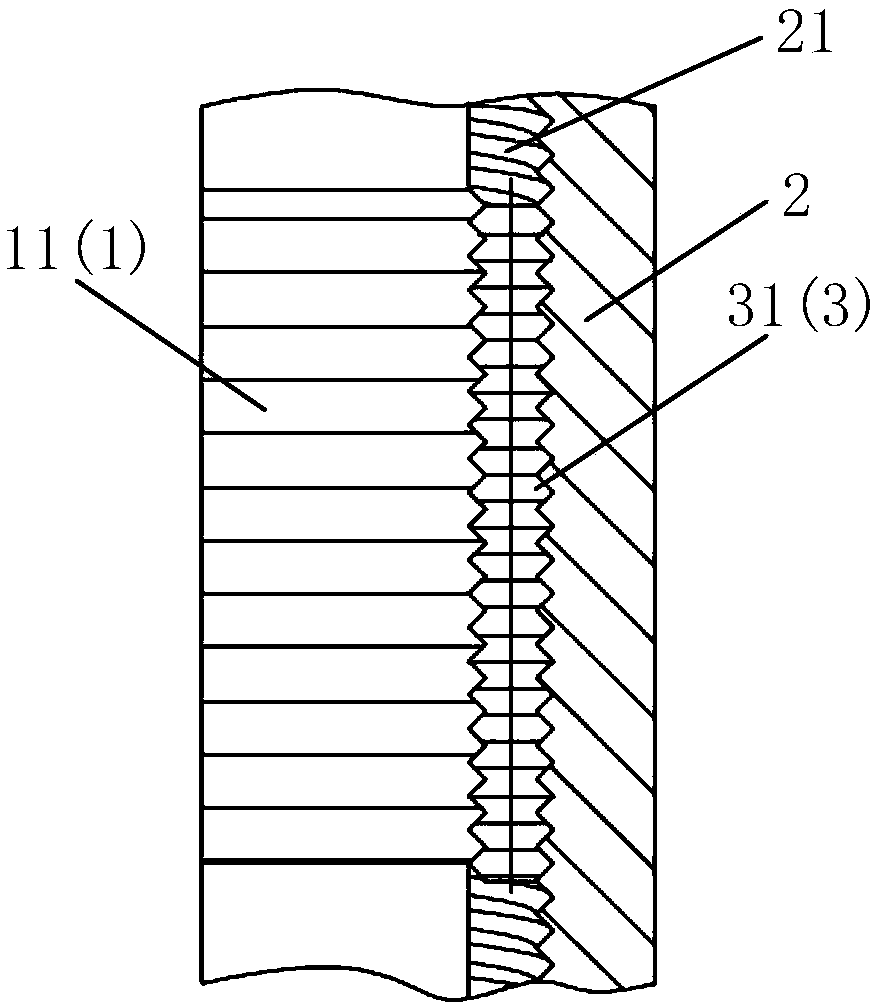

[0040] Such as Figure 1 to Figure 4 As shown, the present invention provides a planetary roller screw, which includes a screw 1 , a sleeve 2 and a roller 3 .

[0041] The screw rod 1 is cylindrical as a whole, and the outer periphery of the screw rod 1 is provided with a plurality of first grooves 11 extending along the circumferential direction C, for example, the number of the first grooves 11 is greater than or equal to two. A plurality of first grooves 11 are arranged parallel to each other. The first trench 11 is formed in a closed ring shape, and a cross section of the first trench 11 along a plane perpendicular to the extending direction of the first trench 11 may be, for example, triangular. The plane where the first groove 11 is located may be perpendicular to the axis A of the screw rod 1 .

[0042] The shaft sleeve 2 may be cylindrical as a whole, and the shaft sleeve 2 is sleeved on the screw rod 1, and the axis of the shaft sleeve 2 and the axis of the screw ro...

no. 2 approach

[0052] The overall structure of the planetary roller screw according to the second embodiment of the present invention is the same as that of the first embodiment. In the present embodiment, the same reference numerals are assigned to the same or similar components as those in the first embodiment, and detailed descriptions of these components will be omitted.

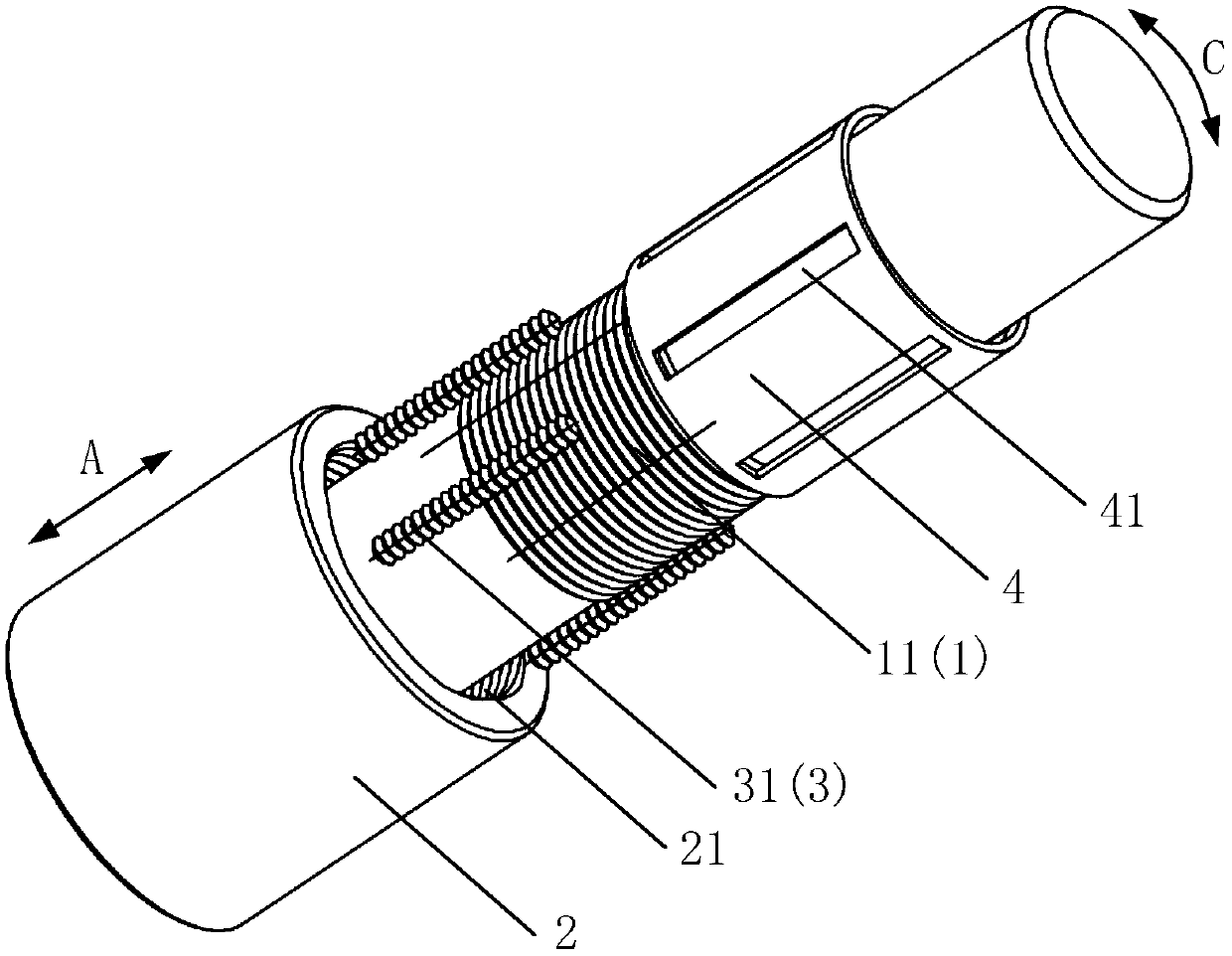

[0053] Such as Figure 5 to Figure 7 As shown, the present invention provides a planetary roller screw, which includes a screw 1 , a sleeve 2 and a roller 3 .

[0054] The screw rod 1 is cylindrical as a whole, and a plurality of first grooves 11 extending along the circumferential direction C are arranged on the outer periphery of the screw rod 1 . The first groove 11 is formed in a closed ring shape. A plurality of first grooves 11 are arranged parallel to each other, and any two adjacent first grooves 11 may have the same distance.

[0055] The shaft sleeve 2 may be cylindrical as a whole, and the shaft sleeve 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com