Flame-retardant polymer gel electrolyte, preparation method thereof and lithium battery

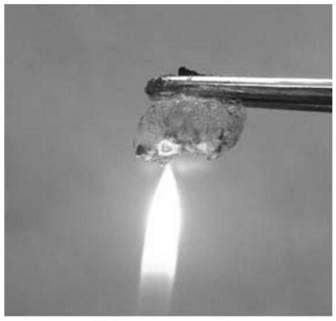

A flame retardant polymer, gel electrolyte technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, electrolyte immobilization/gelation and other directions, can solve the problems of easy decomposition, strong fluidity, low flash point, etc. Achieve the effect of improving cycle stability and improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

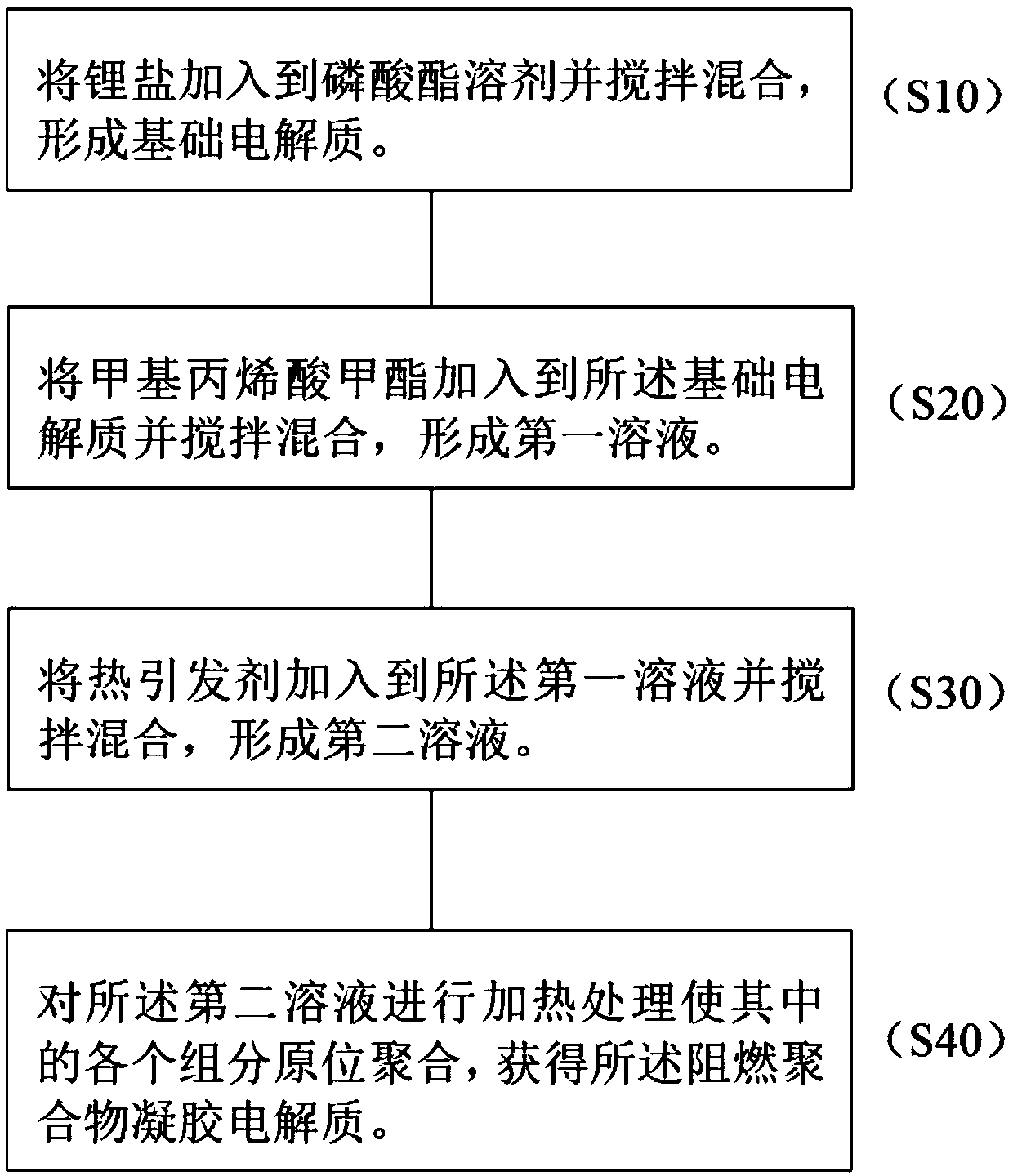

[0032] The embodiment of the present invention provides the preparation method of the flame-retardant polymer gel electrolyte as described above, such as figure 1 Shown, described preparation method comprises steps:

[0033] S10, adding the lithium salt to the phosphate ester solvent and stirring to form a basic electrolyte.

[0034] In a specific solution, when lithium salt is added to the phosphate ester solvent, it is stirred at a temperature of 15° C. to 25° C. for 0.5 to 3 hours to completely dissolve the lithium salt and form a basic electrolyte with a high salt solubility ratio. Preferably, the molar concentration of the lithium salt in the basic electrolyte is 3-7 mol / L.

[0035] S20, adding methyl methacrylate to the basic electrolyte and stirring to form a first solution.

[0036] In a specific scheme, when methyl methacrylate is added to the basic electrolyte, it is stirred at a temperature of 15° C. to 25° C. for 0.5 to 2 hours, so that the methyl methacrylate is...

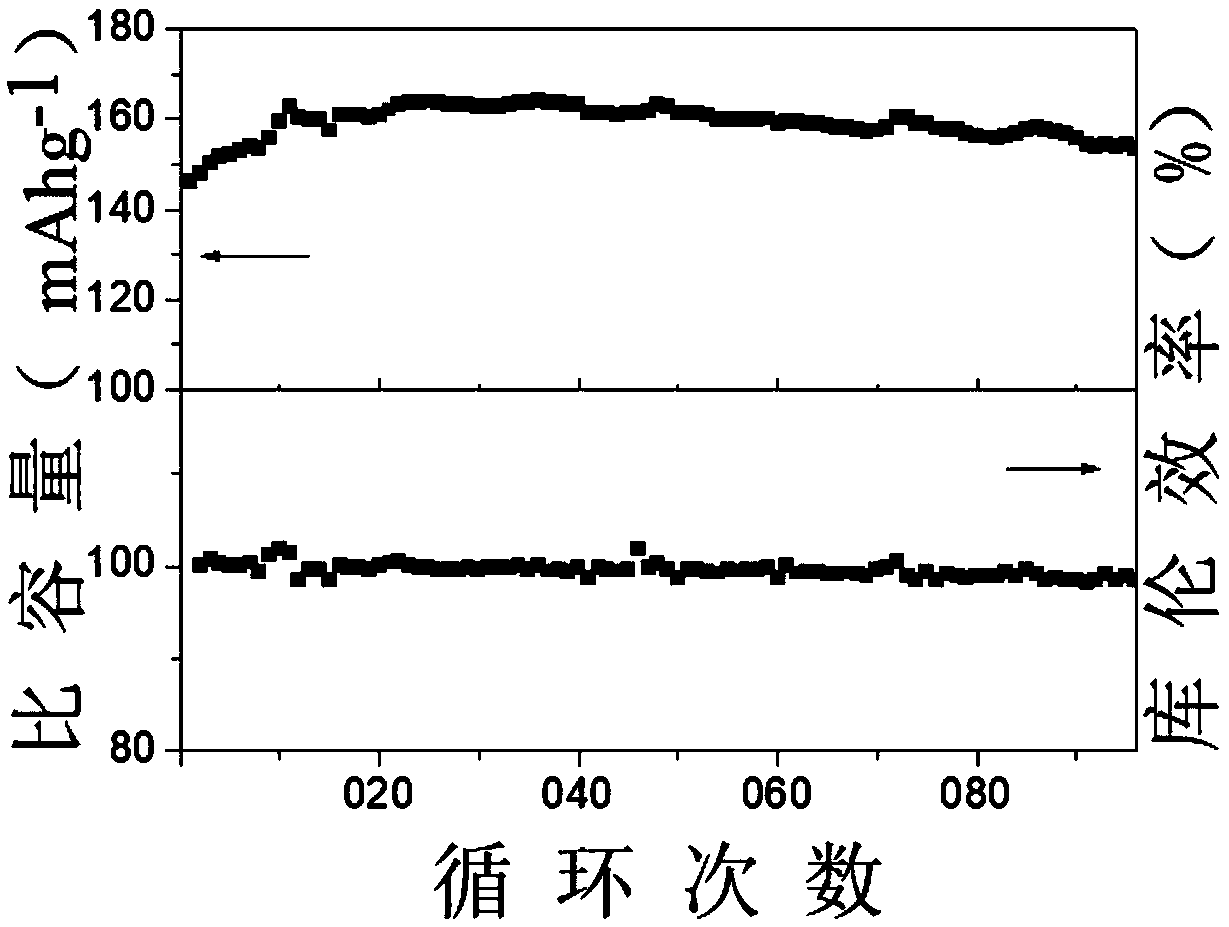

Embodiment 1

[0044] The flame retardant polymer gel electrolyte provided in this embodiment includes the following components by weight ratio: 71.33% of basic electrolyte, 28.53% of methyl methacrylate and 0.14% of azobisisobutyronitrile, through heat treatment The above components are polymerized in situ to form the flame retardant polymer gel electrolyte. Wherein, the basic electrolyte is a basic electrolyte formed by dissolving lithium bis(fluorosulfonyl)imide in trimethyl phosphate solvent, and in the basic electrolyte, the molar fraction of lithium bis(fluorosulfonyl)imide is 7mol / L.

[0045] The preparation method of the flame retardant polymer gel electrolyte in this embodiment is as follows:

[0046] (1) Dissolve 3.3 g of lithium bis(fluorosulfonyl)imide in 2.5 mL of trimethyl phosphate solvent, and stir at 20°C for 1 h until the lithium bis(fluorosulfonyl)imide is completely dissolved A basic electrolyte with a high concentration of lithium salt is formed. In the basic electrol...

Embodiment 2

[0052] The flame retardant polymer gel electrolyte provided by this embodiment includes the following components by weight ratio: 71.23% of basic electrolyte, 28.49% of methyl methacrylate and 0.28% of azobisisobutyronitrile, through heat treatment The above components are polymerized in situ to form the flame retardant polymer gel electrolyte. Wherein, the basic electrolyte is a basic electrolyte formed by dissolving lithium bistrifluoromethanesulfonylimide in a triethyl phosphate solvent, and in the basic electrolyte, the molar fraction of lithium bistrifluoromethanesulfonylimide is 5mol / L.

[0053] The preparation method of the flame retardant polymer gel electrolyte in this embodiment is as follows:

[0054] (1) Dissolve 2.3 g of lithium bistrifluoromethanesulfonyl imide in 2.5 mL of triethyl phosphate solvent, and stir at a temperature of 15° C. for 3 h until the lithium bistrifluoromethanesulfonyl imide is completely dissolved A basic electrolyte with a high concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com