Method for maintaining liquid state of high concentration myosin at high temperature

A myosin, high-concentration technology, used in the field of high-concentration myosin maintaining liquid state at high temperature, can solve problems such as restricting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

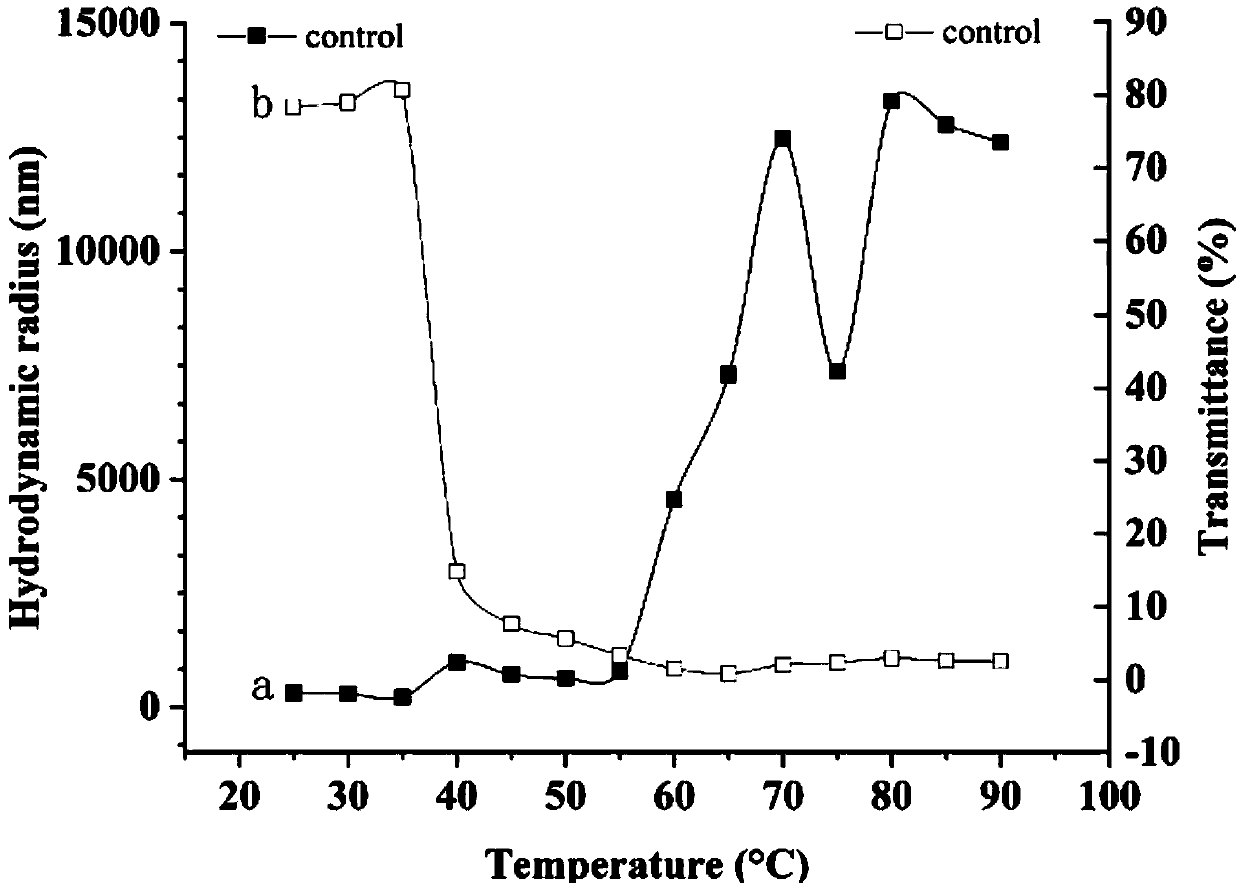

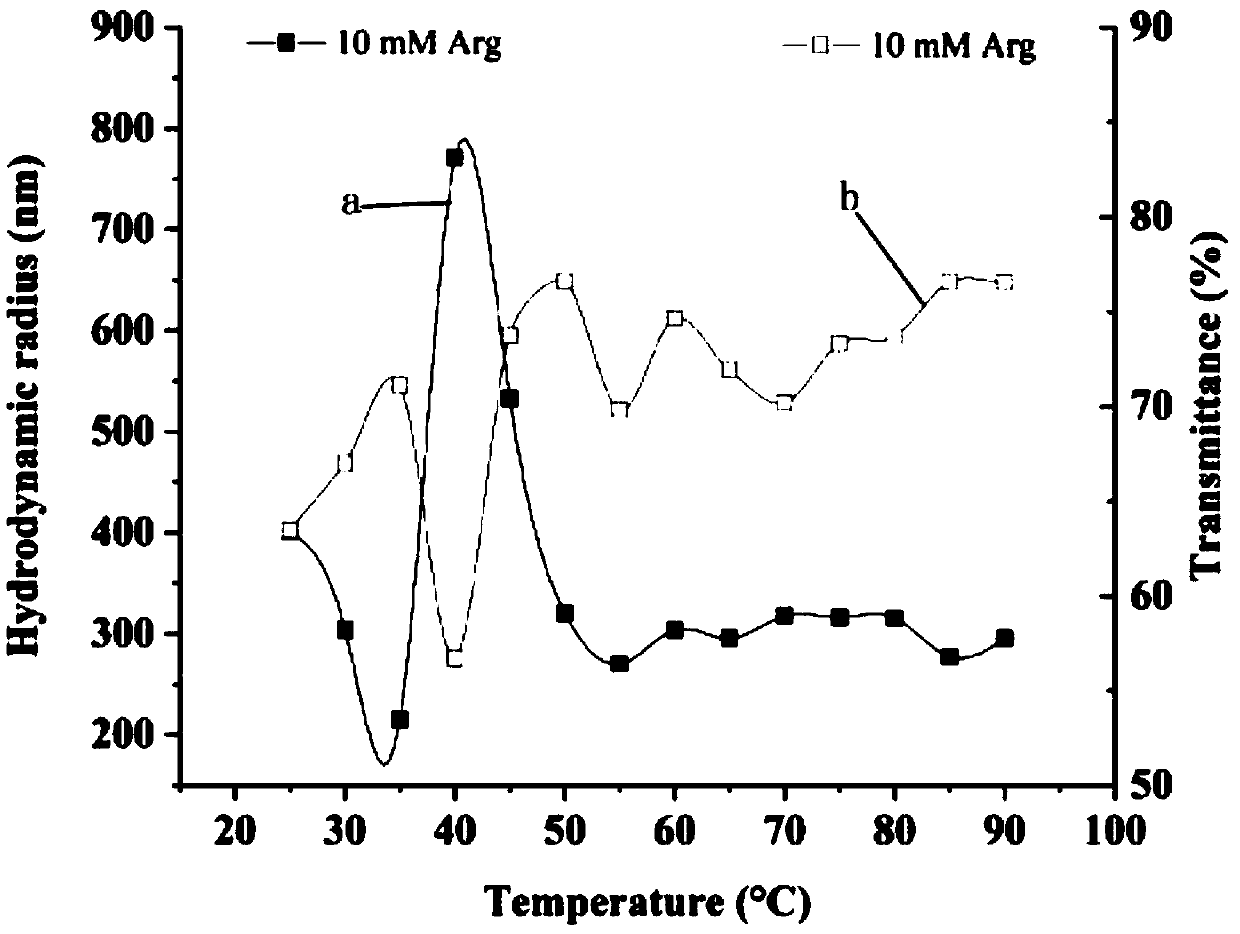

Examples

Embodiment 1

[0031] (1) Cleaning and peeling of fish meat: rinse the silver carp with clear water, select the back fish meat, clean and peel;

[0032] (2) Extraction of myosin: slaughter fresh silver carp, take back fish meat, peel, wash, chop into minced meat, add 10 times the volume of reagent A, homogenize at 11000r / min with a homogenizer Massage for 3-5 minutes, react at 4°C for 15 minutes, centrifuge (3000×g, 5min, 4°C), take the precipitate, add 5 times the volume of reagent B, and add ATP to the suspension to make the final concentration 10mM, After fully dissolving, place the above mixture at 4°C for 90min, centrifuge (11000×g, 13min, 4°C), add 5 times the volume of 1mM potassium bicarbonate to the supernatant, and place it at 4°C for 20min, then Centrifuge (11000×g, 13min, 4°C), take the precipitate, add 2.5 times the volume of reagent C, react it at 4°C for 10min, then add 5 times the volume of 1mM potassium bicarbonate and magnesium chloride successively to make the mixture The...

Embodiment 2

[0040] (1) Cleaning and peeling of fish meat: rinse the silver carp with clear water, select the back fish meat, clean and peel;

[0041] (2) Extraction of myosin: slaughter fresh silver carp, take back fish meat, peel, wash, chop into minced meat, add 10 times the volume of reagent A, homogenize at 11000r / min with a homogenizer Massage for 3-5 minutes, react at 4°C for 15 minutes, centrifuge (3000×g, 5min, 4°C), take the precipitate, add 5 times the volume of reagent B, and add ATP to the suspension to make the final concentration 10mM, After fully dissolving, place the above mixture at 4°C for 90min, centrifuge (11000×g, 13min, 4°C), add 5 times the volume of 1mM potassium bicarbonate to the supernatant, and place it at 4°C for 20min, then Centrifuge (11000×g, 13min, 4°C), take the precipitate, add 2.5 times the volume of reagent C, react it at 4°C for 10min, then add 5 times the volume of 1mM potassium bicarbonate and magnesium chloride successively to make the mixture The...

Embodiment 3

[0049] (1) Cleaning and peeling of fish meat: rinse the silver carp with clear water, select the back fish meat, clean and peel;

[0050] (2) Extraction of myosin: slaughter fresh silver carp, take back fish meat, peel, wash, chop into minced meat, add 10 times the volume of reagent A, homogenize at 11000r / min with a homogenizer Massage for 3-5 minutes, react at 4°C for 15 minutes, centrifuge (3000×g, 5min, 4°C), take the precipitate, add 5 times the volume of reagent B, and add ATP to the suspension to make the final concentration 10mM, After fully dissolving, place the above mixture at 4°C for 90min, centrifuge (11000×g, 13min, 4°C), add 5 times the volume of 1mM potassium bicarbonate to the supernatant, and place it at 4°C for 20min, then Centrifuge (11000×g, 13min, 4°C), take the precipitate, add 2.5 times the volume of reagent C, react it at 4°C for 10min, then add 5 times the volume of 1mM potassium bicarbonate and magnesium chloride successively to make the mixture The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com