A beneficiation process for processing high-sulfur red-magnetic mixed iron ore

An iron ore, high-sulfur technology, used in solid separation, chemical instruments and methods, wet separation, etc., can solve the problems of low efficiency of cyclones, affecting the re-election index, and large circulation compliance, so as to reduce overgrinding. production, lower production costs, and the effect of sufficient competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

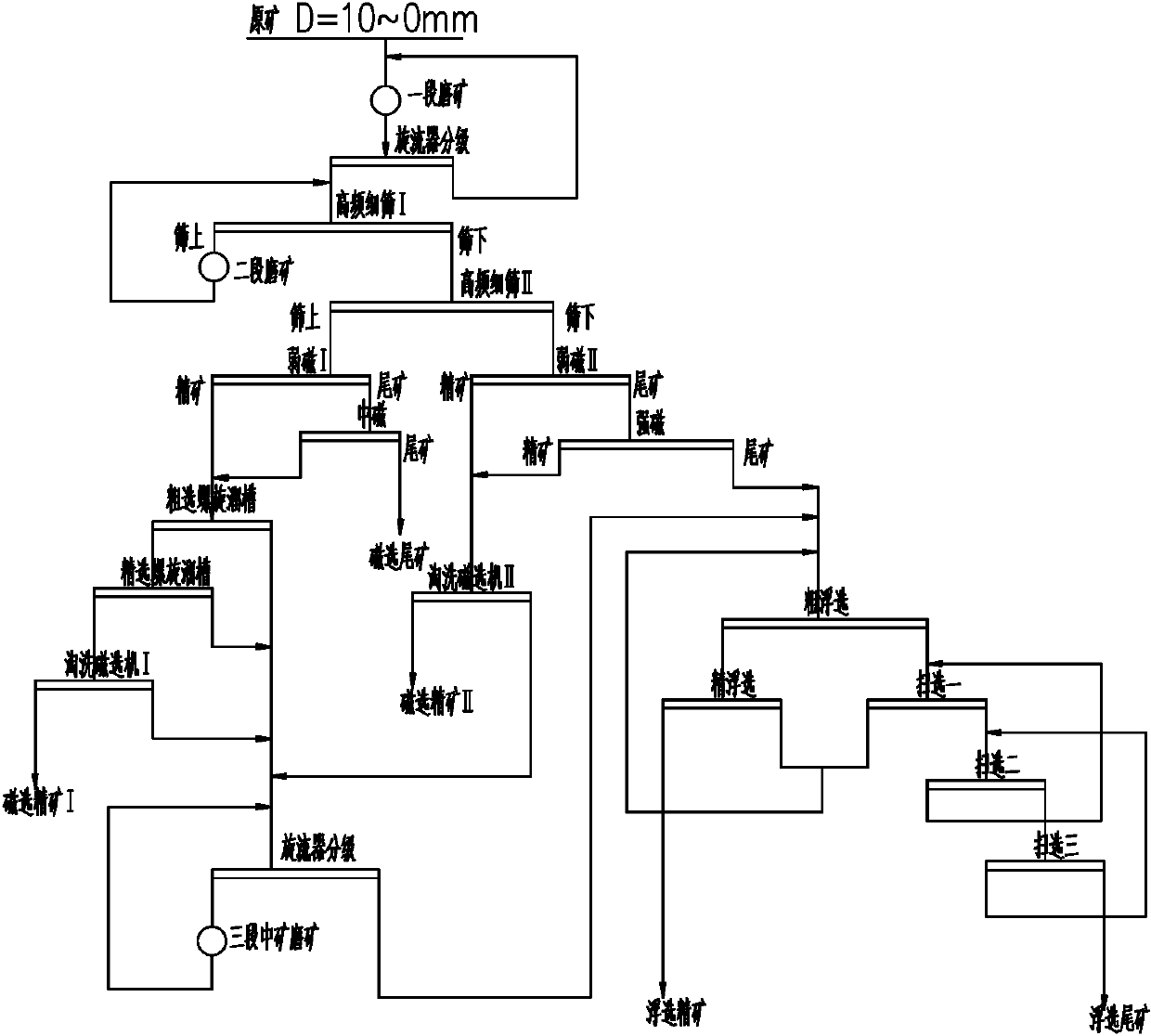

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

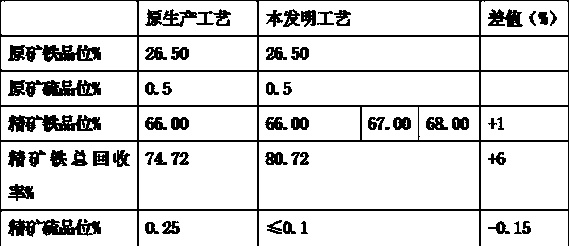

[0028] Such as figure 1 As shown, a kind of beneficiation process for processing high-sulfur red-magnetic mixed iron ore of the present invention is to process the raw ore produced by a certain iron mine in Hebei. The raw ore with an iron grade of 25%-27%, a sulfur grade of 0.4%-0.6%, and a particle size of -10.mm is fed into a section of closed-circuit grinding to obtain a closed-circuit section with an overflow particle size of -0.074mm of 58%-62%. Grinding overflow products are characterized in that: the one-stage closed-circuit grinding overflow product is obtained by two-stage closed-circuit grinding to obtain -0.3mm product, and the -0.3mm product is coarsely classified by high-frequency fine screen II to obtain 0.3mm-0.074 Coarse-grained products on the sieve of mm and fine-grained products under the sieve of -0.074mm, for the coarse-grained products on the siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com