Thermal insulation material packaging machine

A thermal insulation material and packaging machine technology, applied in the field of building materials, can solve problems such as complicated procedures, low work efficiency, and impact on the production progress of thermal insulation materials, so as to achieve low manufacturing difficulty, improve production efficiency, and improve happiness and enjoyment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

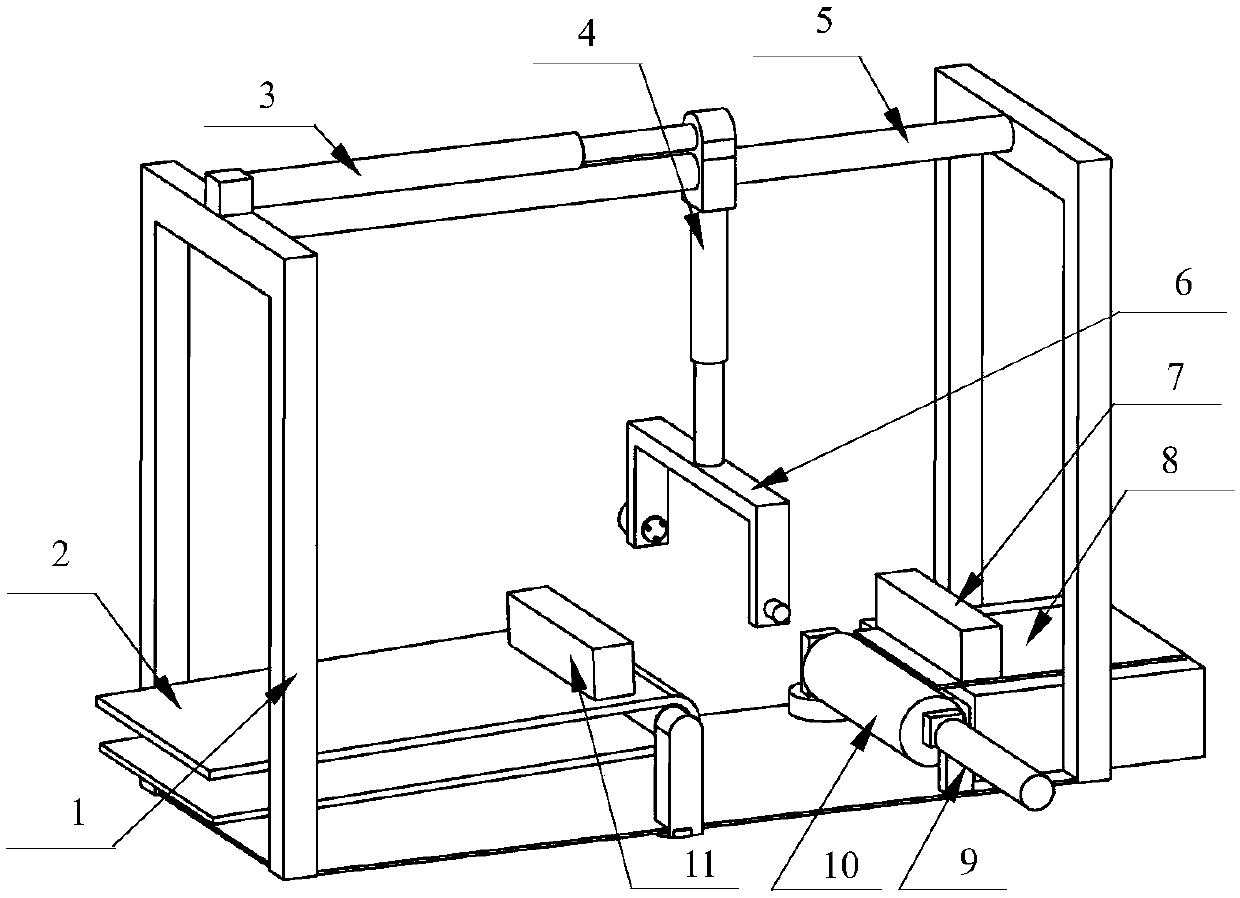

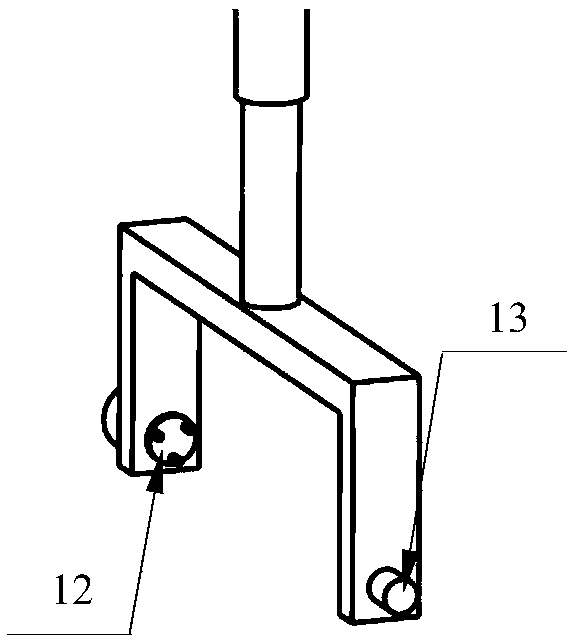

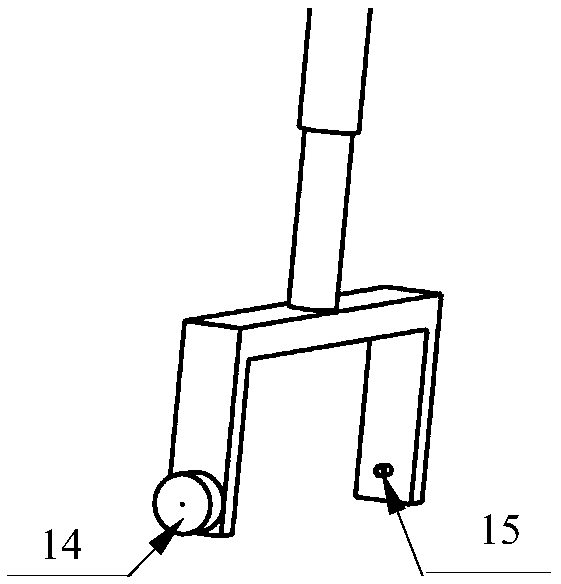

[0013] like figure 1 As shown, the thermal insulation material packaging machine is composed of a frame 1, a conveyor belt 2, a mechanical arm 3, an ultrasonic cutter 9 and a rotating brush 10. The frame 1 is two "door" structures with the same shape connected by the sliding rod 5; the conveyor belt 2 is used to transfer the thermal insulation material to the position of the thermal insulation material 11 to be packaged so that the mechanical arm 3 can grab it; the mechanical arm 3 is controlled by the sliding block 4. The end effector 6 is composed of two linear motors vertically connected by the sliding block 4, wherein the linear motor parallel to the sliding rod 5 is fixed on the frame 1, the sliding block 4 is set on the sliding rod 5, and the other linear motor The lower end of the moving part is connected with the end effector 6 . The end effector 6 is in the shape of a "door". A motor 14 is installed near one end, and its shaft is connected to the three-jaw turntable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com