High-purity hydrochloric acid production process

A production process, high-purity hydrochloric acid technology, applied in the direction of chlorine/hydrogen chloride, hydrogen chloride preparation, etc., can solve the problems of reducing equipment life, reducing the quality of secondary brine, and breaking ion exchange resins, achieving obvious advantages, improving service life, and increasing The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

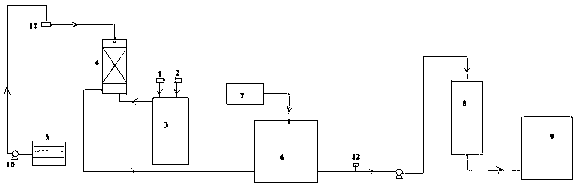

[0023] The production technology of embodiment 1 high-purity hydrochloric acid, with reference to figure 1 , including the following steps:

[0024] (1) The raw chlorine and hydrogen with a purity of 99% enter from the top of the synthesis furnace respectively. The chlorine and hydrogen are burned on the combustion platform of the synthesis furnace to produce white hydrogen chloride gas. The hydrogen chloride gas enters the cooling absorption tower from the top of the furnace and is cooled by water. When the temperature drops to 55°C, the water in the cooling tower absorbs hydrogen chloride gas to generate hydrochloric acid with a concentration of 31%, which flows into the hydrochloric acid storage tank; among them, the water in the cooling tower is steam condensed water, which is continuously added. Add to cooling absorption tower through lift pump and water jet pump;

[0025] (2) According to the content of free chlorine in the hydrochloric acid storage tank, prepare a sodi...

Embodiment 2

[0027] The production technology of embodiment 2 high-purity hydrochloric acid, with reference to figure 1 , including the following steps:

[0028] (1) The raw chlorine and hydrogen with a purity of 99% enter from the top of the synthesis furnace respectively. The chlorine and hydrogen are burned on the combustion platform of the synthesis furnace to produce white hydrogen chloride gas. The hydrogen chloride gas enters the cooling absorption tower from the top of the furnace and is cooled by water. When the temperature drops to 50°C, the water in the cooling tower absorbs hydrogen chloride gas to generate hydrochloric acid with a concentration of 31%, which flows into the hydrochloric acid storage tank; among them, the water in the cooling tower is steam condensed water, which is continuously added. Add to cooling absorption tower through lift pump and water jet pump;

[0029] (2) According to the content of free chlorine in the hydrochloric acid storage tank, prepare a sodi...

Embodiment 3

[0031] The production technique of embodiment 3 high-purity hydrochloric acid, with reference to figure 1 , including the following steps:

[0032] (1) The raw chlorine and hydrogen with a purity of 99% enter from the top of the synthesis furnace respectively. The chlorine and hydrogen are burned on the combustion platform of the synthesis furnace to produce white hydrogen chloride gas. The hydrogen chloride gas enters the cooling absorption tower from the top of the furnace and is cooled by water. When the temperature drops to 50°C, the water in the cooling tower absorbs hydrogen chloride gas to generate hydrochloric acid with a concentration of 31%, which flows into the hydrochloric acid storage tank; among them, the water in the cooling tower is steam condensed water, which is continuously added. Add to cooling absorption tower through lift pump and water jet pump;

[0033] (2) According to the content of free chlorine in the hydrochloric acid storage tank, prepare a sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com