Hierarchical pore ZSM-5 molecular sieve, and preparation method and application thereof

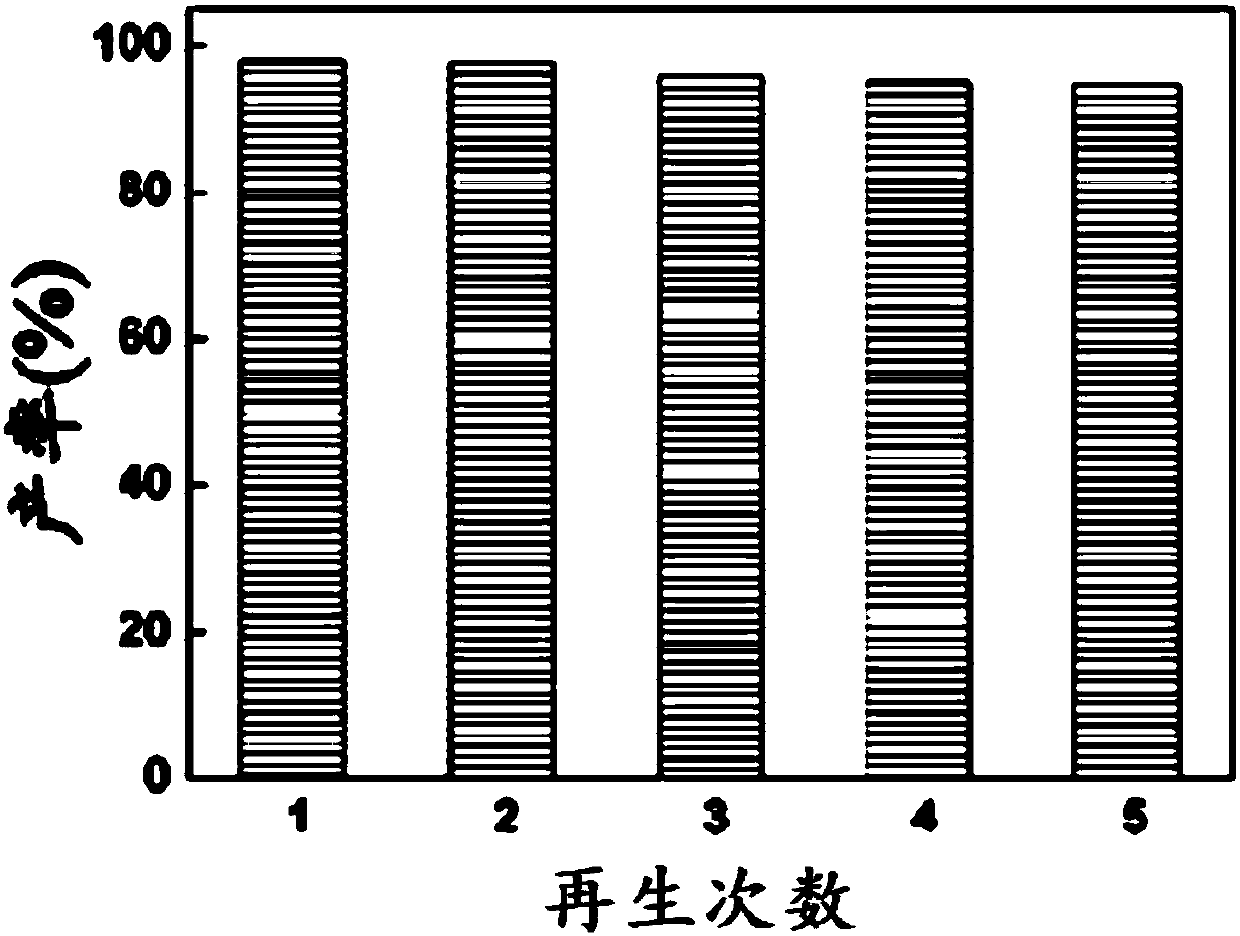

A ZSM-5, multi-stage pore technology, applied in the field of molecular sieves, can solve the problems of difficulty in subsequent separation of products, increase in product production costs, and difficulty in improving the yield of 2,5-furandimethanol dimethyl ether, and achieve good application. Prospect, effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

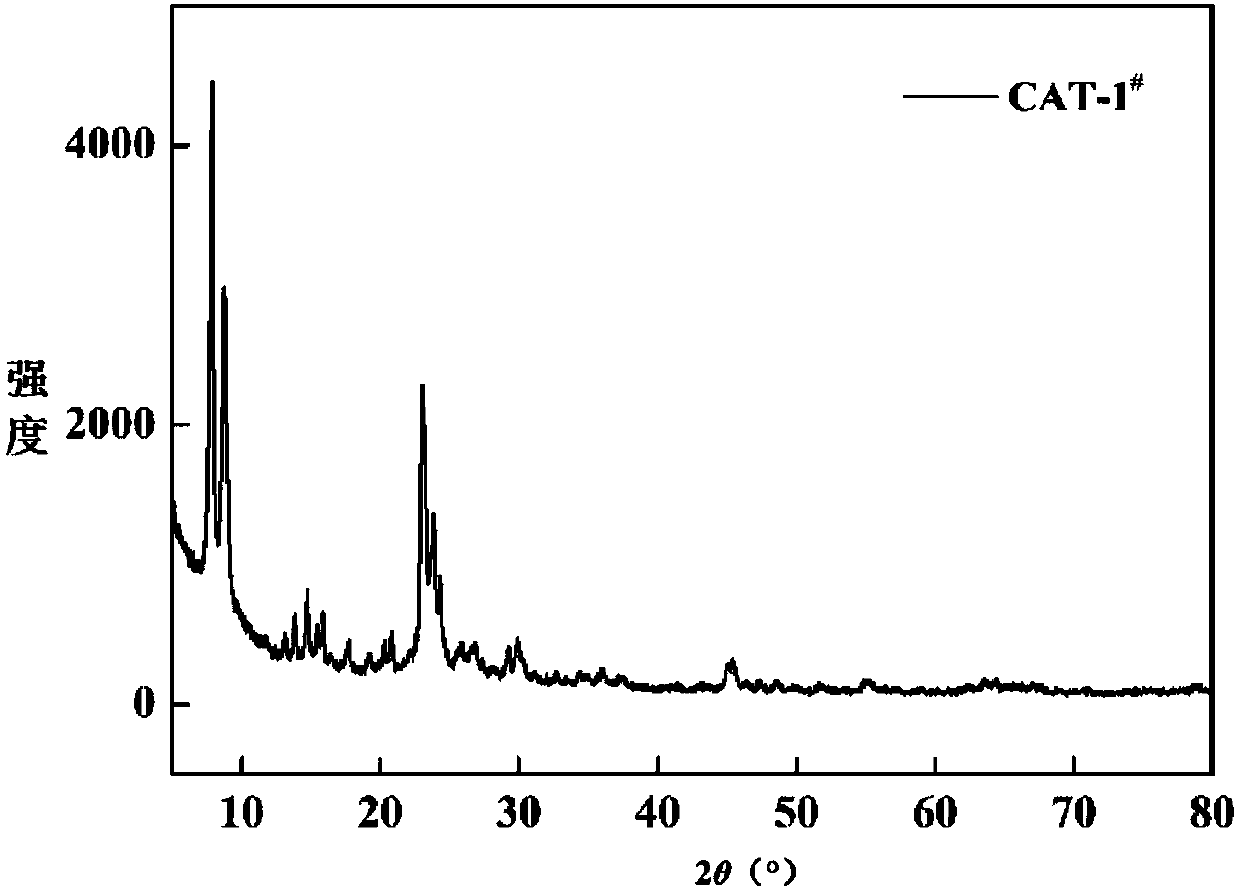

[0094] Example 1 Sample 1 # preparation

[0095] Mix 0.59g of aluminum isopropoxide, 12g of tetrapropylammonium hydroxide, 13mL of ethyl orthosilicate, 1.6mL of hexadecyltrimethoxysilane and 50mL of ethanol in a beaker, and stir at 25°C until a gel is formed; The gel was dried at 25°C for 72h, and then transferred to a 250mL stainless steel hydrothermal kettle with a polytetrafluoroethylene liner. The polytetrafluoroethylene liner contained 50mL of water and crystallized at 170°C for 75h; filtered and washed After that, the multi-stage porous ZSM-5 molecular sieve sample was obtained, which was designated as sample 1 # .

Embodiment 2

[0096] Example 2 Sample 2 # preparation of

[0097] Mix 0.40g of aluminum isopropoxide, 12g of tetrapropylammonium hydroxide, 13mL of ethyl orthosilicate, 1.6mL of hexadecyltrimethoxysilane and 50mL of ethanol in a beaker, and stir at 25°C until a gel is formed; The gel was dried at 25°C for 72h, and then transferred to a 250mL stainless steel hydrothermal kettle with a polytetrafluoroethylene liner. The polytetrafluoroethylene liner contained 50mL of water and crystallized at 175°C for 70h; filtered and washed After that, the multi-stage porous ZSM-5 molecular sieve sample was obtained, which was designated as sample 2 # .

Embodiment 3

[0098] Example 3 Sample 3 # preparation of

[0099] Mix 0.238g of aluminum isopropoxide, 12g of tetrapropylammonium hydroxide, 13mL of ethyl orthosilicate, 1.6mL of hexadecyltrimethoxysilane and 50mL of ethanol in a beaker, and stir at 25°C until a gel is formed; The gel was dried at 25°C for 72h, and then transferred to a 250mL stainless steel hydrothermal kettle with a polytetrafluoroethylene liner. The polytetrafluoroethylene liner contained 50mL of water and crystallized at 175°C for 72h; filtered and washed After that, the multi-stage porous ZSM-5 molecular sieve sample was obtained, which was designated as sample 3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com