Application of viscosity reducing polycarboxylic acid water reducer in preparing C100 concrete

A viscous polycarboxylic acid and concrete technology, applied in the field of concrete admixtures, can solve the problems of reducing water evaporation shrinkage force, reducing surface tension, high viscosity, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

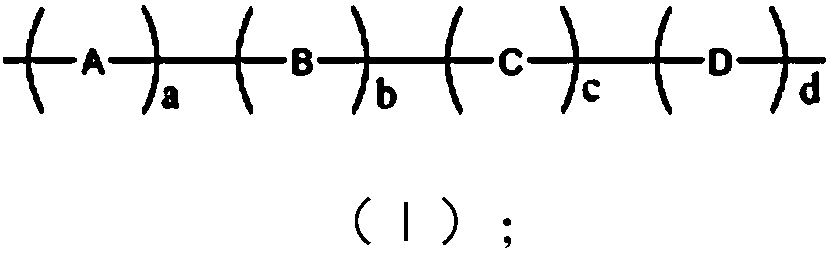

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

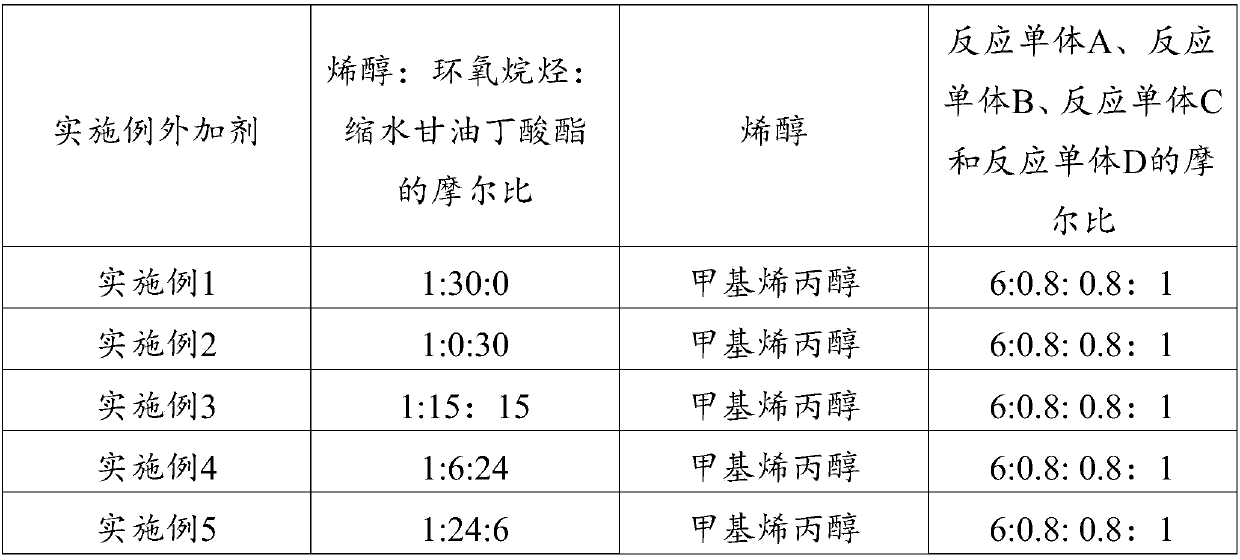

Embodiment 1

[0062] The preparation method of the viscosity-reducing polycarboxylate water reducer of the present invention, the preparation method comprises the following steps:

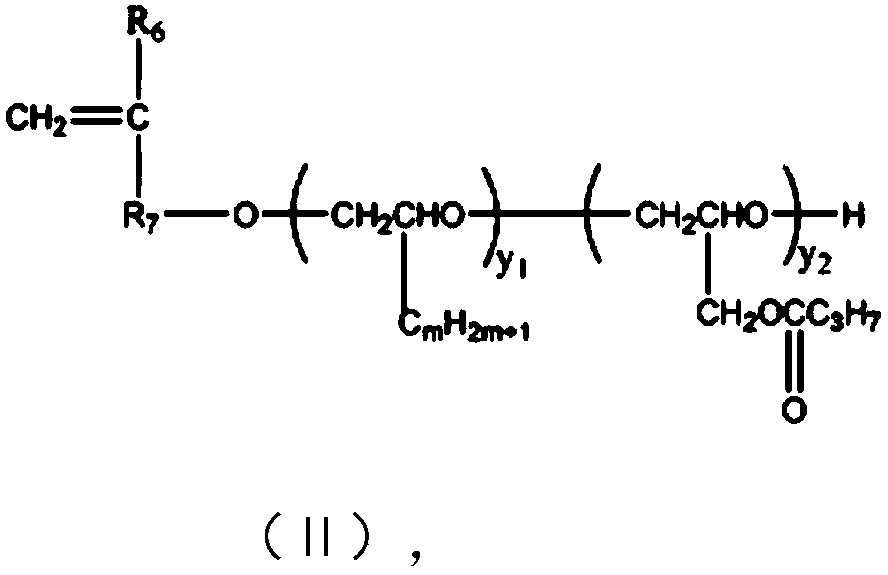

[0063] (1) Synthesis of viscosity-reducing active macromonomer D:

[0064] In a four-necked glass flask equipped with a stirrer, a thermometer, a reflux condenser, and a dropping device, add 1 mol of methallyl alcohol, 2 g of sodium hydride, stir under nitrogen protection, and dropwise add 30 mol of The oxyalkane was added dropwise in 3 hours, and the reaction was continued at 100°C for 8 hours to obtain the viscosity-reducing active macromonomer D.

[0065] (2) Synthesis of viscosity-reducing polycarboxylate superplasticizer

[0066] Dissolving reactive monomer B, reactive monomer C, reactive monomer D, and oxidizing agent in water to obtain solution 1, dissolving reactive monomer A and chain transfer agent in water to obtain solution 2, dissolving reducing agent in water to obtain solution 3, Under normal te...

Embodiment 2

[0070] The preparation method of the viscosity-reducing polycarboxylate water reducer of the present invention, the preparation method comprises the following steps:

[0071] (1) Synthesis of viscosity-reducing active macromonomer D:

[0072] In a four-necked glass flask equipped with a stirrer, a thermometer, a reflux condenser, and a dropping device, add 1 mol of methallyl alcohol, 2 g of sodium hydride, stir under nitrogen protection, and dropwise add 30 mol of Glycerin butyrate was added dropwise in 3 hours, and the reaction was continued at 100°C for 8 hours to obtain the viscosity-reducing active macromonomer D.

[0073] (2) Synthesis of viscosity-reducing polycarboxylate superplasticizer

[0074] Dissolving reactive monomer B, reactive monomer C, reactive monomer D, and oxidizing agent in water to obtain solution 1, dissolving reactive monomer A and chain transfer agent in water to obtain solution 2, dissolving reducing agent in water to obtain solution 3, Under norma...

Embodiment 3

[0078] The preparation method of the viscosity-reducing polycarboxylate water reducer of the present invention, the preparation method comprises the following steps:

[0079] (1) Synthesis of viscosity-reducing active macromonomer D:

[0080] In a four-necked glass flask equipped with a stirrer, a thermometer, a reflux condenser, and a dropping device, add 1 mol of methallyl alcohol, 2 g of sodium hydride, stir under nitrogen protection, and dropwise add 15 mol of ring Oxyalkane and 15mol glycidyl butyrate were added dropwise in 3 hours, and the reaction was continued at 100°C for 8 hours to obtain the viscosity-reducing active macromonomer D.

[0081] (2) Synthesis of viscosity-reducing polycarboxylate superplasticizer

[0082] Dissolving reactive monomer B, reactive monomer C, reactive monomer D, and oxidizing agent in water to obtain solution 1, dissolving reactive monomer A and chain transfer agent in water to obtain solution 2, dissolving reducing agent in water to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com