Solid asbestos crystal material and preparation method thereof

A crystal material and asbestos technology, applied in the field of solid asbestos crystal material and its preparation, can solve the problems of human and animal health hazards, geological hazards, etc., and achieve the effects of reducing production costs, solving land occupation, and improving thermal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

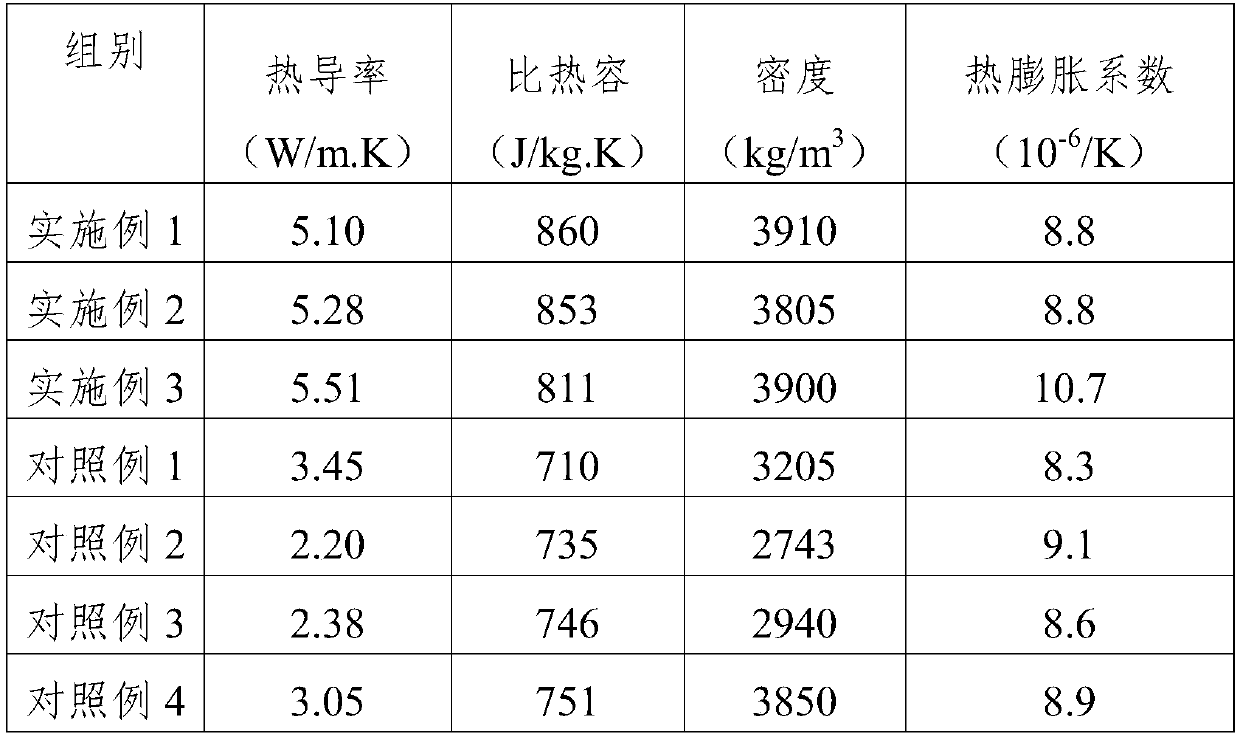

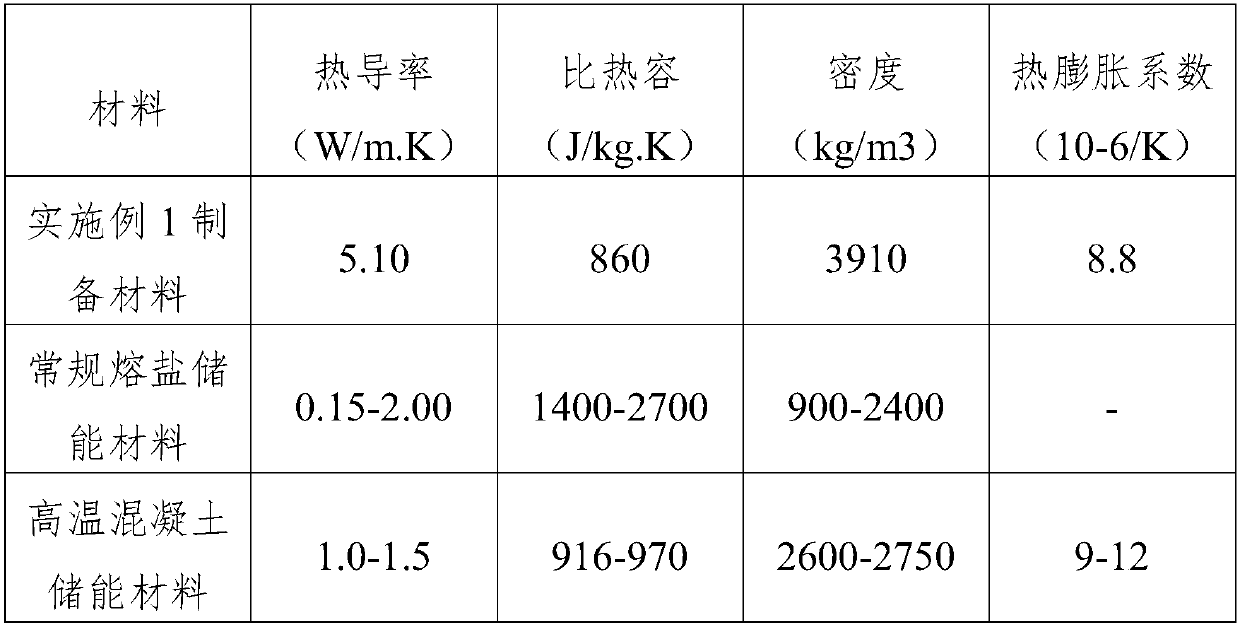

Examples

Embodiment 1

[0038] 1. Solid asbestos crystal material

[0039] The above-mentioned solid asbestos crystal material includes the following raw materials in parts by weight:

[0040] 60 parts of asbestos tailings, 15 parts of quartz sand, 20 parts of limestone, 2 parts of calcium fluoride, 1 part of aluminum oxide and 0.3 parts of diboron trioxide.

[0041] 2. Preparation method

[0042] The preparation method of above-mentioned solid asbestos crystal material, comprises the steps:

[0043] (a) crushing the asbestos tailings to 0.05-0.15mm, and then mixing the crushed asbestos tailings with quartz sand, limestone, calcium fluoride, aluminum oxide and boron trioxide to obtain a mixture;

[0044] (b) Use plasma torch heating to heat the mixture to 1400°C at 20°C / min and keep it warm for 2 hours; then place the mixture at 800°C and keep it warm for 1 hour; then, heat it up to 1000°C at 10°C / min and keep it warm 2h;

[0045] (c) Putting the mixture into a mold for casting, adopting a normal...

Embodiment 2

[0047] 1. Solid asbestos crystal material

[0048] The above-mentioned solid asbestos crystal material includes the following raw materials in parts by weight:

[0049] 65 parts of asbestos tailings, 10 parts of quartz sand, 25 parts of limestone, 1 part of calcium fluoride, 2.5 parts of aluminum oxide and 0.5 parts of diboron trioxide.

[0050] 2. Preparation method

[0051] The preparation method of above-mentioned solid asbestos crystal material, comprises the steps:

[0052] (a) crushing the asbestos tailings to 0.05-0.15mm, and then mixing the crushed asbestos tailings with quartz sand, limestone, calcium fluoride, aluminum oxide and boron trioxide to obtain a mixture;

[0053] (b) Use plasma torch heating to heat the mixture to 1600°C at 30°C / min and keep it warm for 3h; put the mixture at 700°C and keep it warm for 2h; then, heat it up to 1100°C at 15°C / min and keep it warm 1h;

[0054](c) Putting the mixture into a mold for casting, adopting a normal temperature ai...

Embodiment 3

[0056] 1. Solid asbestos crystal material

[0057] The above-mentioned solid asbestos crystal material includes the following raw materials in parts by weight:

[0058] 62 parts of asbestos tailings, 13 parts of quartz sand, 22 parts of limestone, 1.5 parts of calcium fluoride, 2 parts of aluminum oxide and 0.4 parts of diboron trioxide.

[0059] 2. Preparation method

[0060] The preparation method of above-mentioned solid asbestos crystal material, comprises the steps:

[0061] (a) crushing the asbestos tailings to 0.05-0.15mm, and then mixing the crushed asbestos tailings with quartz sand, limestone, calcium fluoride, aluminum oxide and boron trioxide to obtain a mixture;

[0062] (b) Using plasma torch heating, the mixture is heated to 1500°C at 25°C / min and kept for 2.5h; then the mixture is placed at 750°C and kept for 1.5h; then, the temperature is raised to 1050°C at 12°C / min , keep warm for 1.5h;

[0063] (c) Putting the mixture into a mold for casting, adopting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com