Waterborne transfer coating for disposable destructive anti-counterfeit label

A technology of anti-counterfeiting labels and transfer coatings, which is applied in the direction of polyester coatings, polyurea/polyurethane coatings, coatings, etc., which can solve the problems of not meeting environmental protection requirements and achieve good edge cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

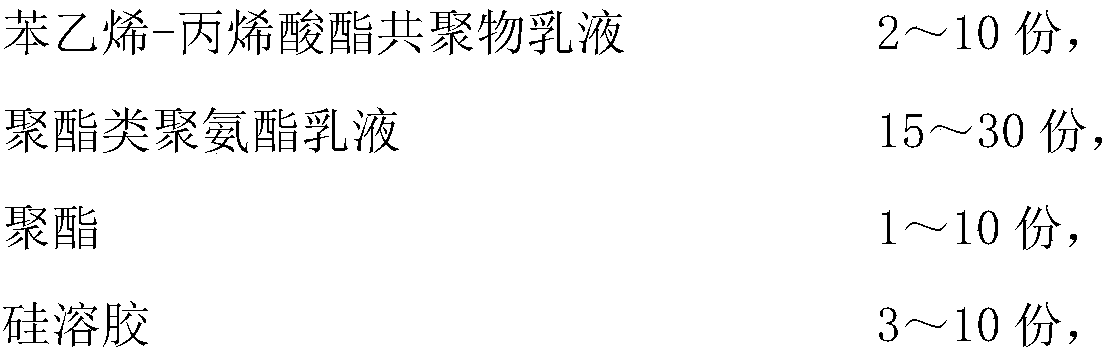

[0028] This embodiment relates to a water-based transfer coating that destroys the anti-counterfeiting label at one time, and the coating adopts the components and contents in Table 1 as raw materials:

[0029] Table 1

[0030] Styrene-acrylate copolymer emulsion

5

Polyester Polyurethane Emulsion

20

polyester

7

Silica sol

8

Ethanol: water (mass ratio 2:1)

60

Polyether modified silicone wetting agent

0.2

Polyether modified silicone defoamer

0.2

[0031] The preparation method of this coating is as follows:

[0032] First mix styrene-acrylic polyester emulsion with polyester polyurethane emulsion and polyester, stir at 300r / min for 10min to fully mix, add silica sol and stir for 5min, then add solvent (ethanol: water 2:1) to dilute, and stir for 5min , then add wetting agent and defoamer in turn, stir at 500r / min for 10min respectively, and discharge.

Embodiment 2

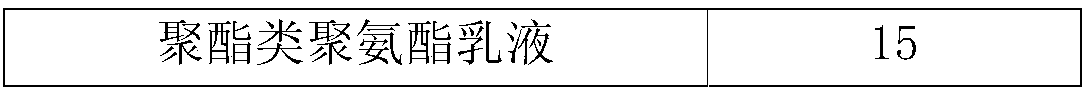

[0034] This embodiment relates to a water-based transfer paint that destroys the anti-counterfeit label at one time. Its preparation method is the same as in Example 1. The paint is made from the components and contents in Table 2:

[0035] Table 2

[0036] Styrene-acrylate copolymer emulsion

Embodiment 3

[0038] This embodiment relates to a water-based transfer paint that destroys the anti-counterfeit label at one time. Its preparation method is the same as that in Example 1. The paint is made from the components and contents in Table 3:

[0039] table 3

[0040] Styrene-acrylate copolymer emulsion

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com