Method for improving drilling drainage concentration of gas in broken coal bodies

A gas drilling and gas drainage technology, which is applied to the drilling composition, gas discharge, earthwork drilling and other directions, can solve the problem of not shortening the effective gas drainage period, increasing the gas leakage, and decreasing the gas drainage concentration, etc. problems, to achieve a good sealing effect, reduce the entry of air, and improve the effect of gas extraction concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

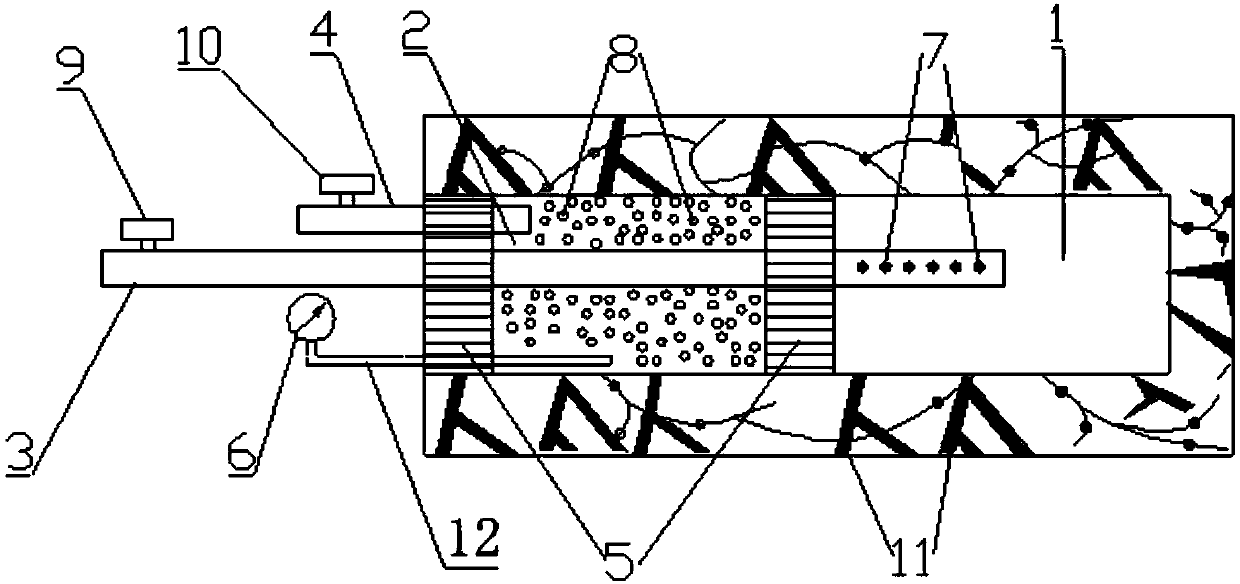

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] Such as figure 1 As shown, a method for improving the concentration of gas borehole drainage in the broken coal body comprises the following steps:

[0026] The first step is to use a drilling rig with a small diameter drill pipe of 30 mm to drill a gas drainage hole 1 on the roadway coal seam according to the conventional drilling method, and use the hole sealer 5 with polyurethane sealing bags installed at both ends to perform preliminary sealing of the hole Form a closed space, and fill the closed space formed by drilling with liquid gel 11 at a pressure not lower than 1.5 MPa;

[0027] The liquid gel 11 includes main material, auxiliary material and water, wherein the main material is a mixture of sodium bentonite and kaolin, and the auxiliary material is a mixture of one or more of sodium tripolyphosphate, sand and sodium chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com