High density phase change memory and preparation method thereof

A phase-change memory, high-density technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as insufficient diode drive current, complex manufacturing process, and inability to meet the operating current requirements of phase change units. , to reduce the number of photolithography, simplify the process, and achieve the effect of high-density storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

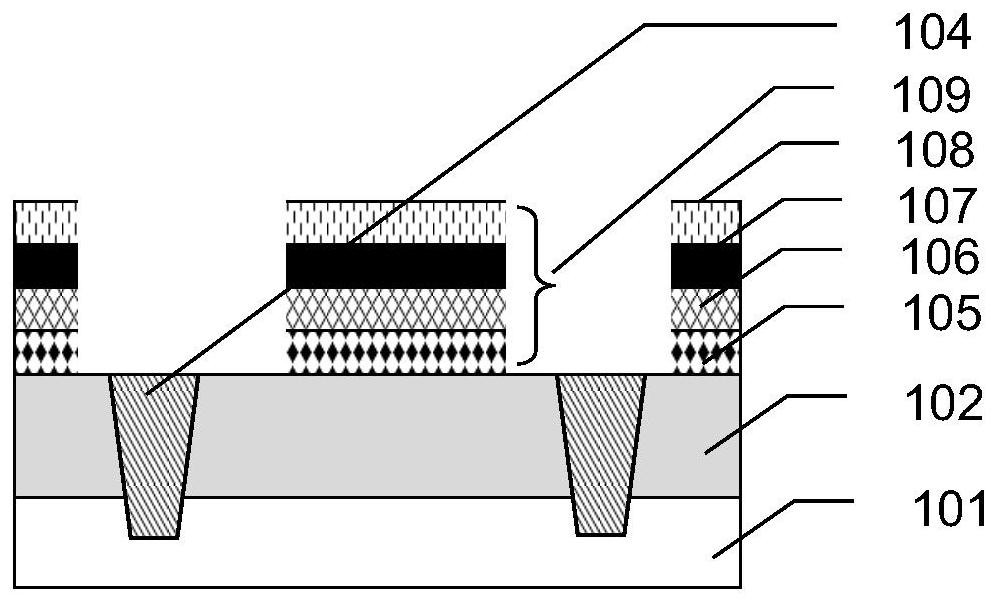

[0045] In the following specific embodiments of the present invention, please refer to figure 1 ,figure 1 It is a schematic structural diagram of a high-density phase change memory according to the first preferred embodiment of the present invention. like figure 1 As shown, a high-density phase change memory of the present invention includes, from bottom to top, Schottky diodes 105 and 106 , a phase change layer 107 and an upper electrode 108 . The Schottky diode includes a semiconductor layer 105 and a metal layer 106 that can form a Schottky barrier with the semiconductor layer 105 ; the metal layer 106 also serves as the lower electrode of the phase change layer 107 .

[0046] The high-density phase change memory of the present invention can be disposed on a semiconductor substrate 101 . The semiconductor layer 105 , the metal layer 106 , the phase change layer 107 and the upper electrode 108 are in a flat layer structure stacked from bottom to top.

[0047] In this embo...

Embodiment 2

[0054] Please refer to Figure 2-Figure 7 , Figure 2-Figure 7 is preparation figure 1 A schematic diagram of the process steps of a high-density phase change memory. like Figure 2-Figure 7 As shown, a method for preparing a high-density phase-change memory of the present invention can be used to prepare a high-density phase-change memory in the above-mentioned first embodiment, and may include the following steps:

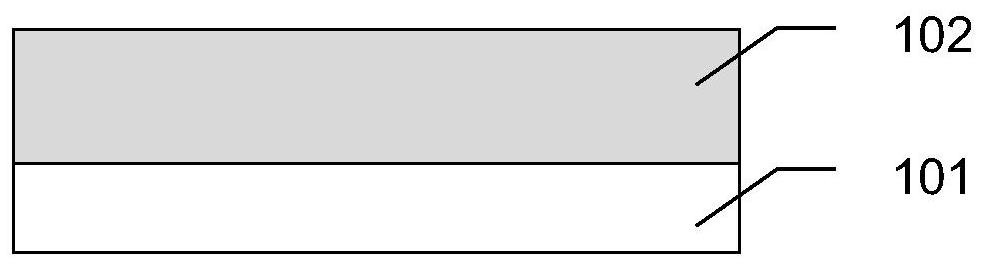

[0055] Step S01 : providing a P-type semiconductor substrate, and forming an N-type heavily doped layer on the surface of the P-type semiconductor substrate.

[0056] like figure 2 As shown, a conventional P-type Si substrate 101 can be used, and an N-type heavily doped layer 102 is formed on the surface of the P-type Si substrate 101 by ion implantation. In this embodiment, the implanted element may be As.

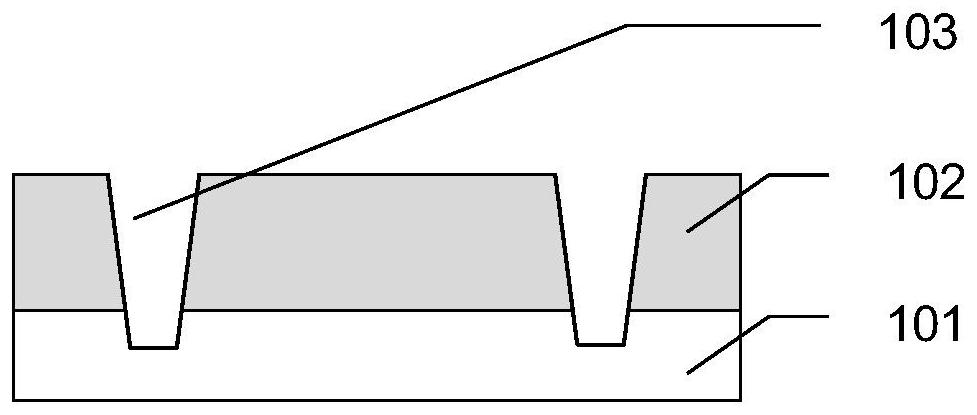

[0057] Step S02 : forming shallow trench isolation on the P-type semiconductor substrate.

[0058] like image 3 As shown, grooves 103 are formed o...

Embodiment 3

[0068] Please refer to Figure 8 , Figure 8 It is a schematic structural diagram of a high-density phase change memory according to the second preferred embodiment of the present invention. like Figure 8 As shown, a high-density phase change memory of the present invention includes, from bottom to top, Schottky diodes 205 and 208 , a phase change layer 211 and an upper electrode 212 . The Schottky diode includes a semiconductor layer 205 and a metal layer 208 that can form a Schottky barrier with the semiconductor layer. The metal layer 208 also serves as the lower electrode of the phase change layer.

[0069] Different from the first embodiment, in this embodiment, the high-density phase change memory can be arranged on a semiconductor substrate 201; The metal layer 208 is connected with a flat bottom surface and vertical sidewalls, that is, it has a cross-sectional shape such as an "L" shape; the metal layer 208 is stacked with the semiconductor layer 205 below it thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com