Aromatic methylation catalyst and preparation method thereof

A catalyst and methylation technology, which is applied in the direction of carbon compound catalysts, catalysts, physical/chemical process catalysts, etc., can solve the problems of difficult preparation, poor stability, and low reactivity of aromatic hydrocarbon methylation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

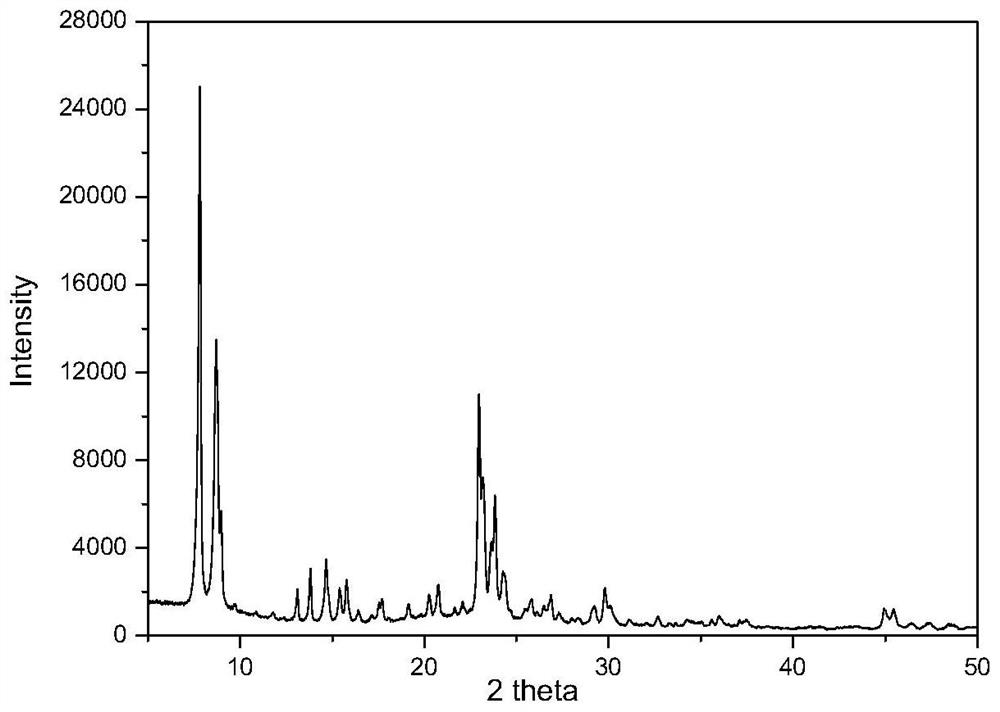

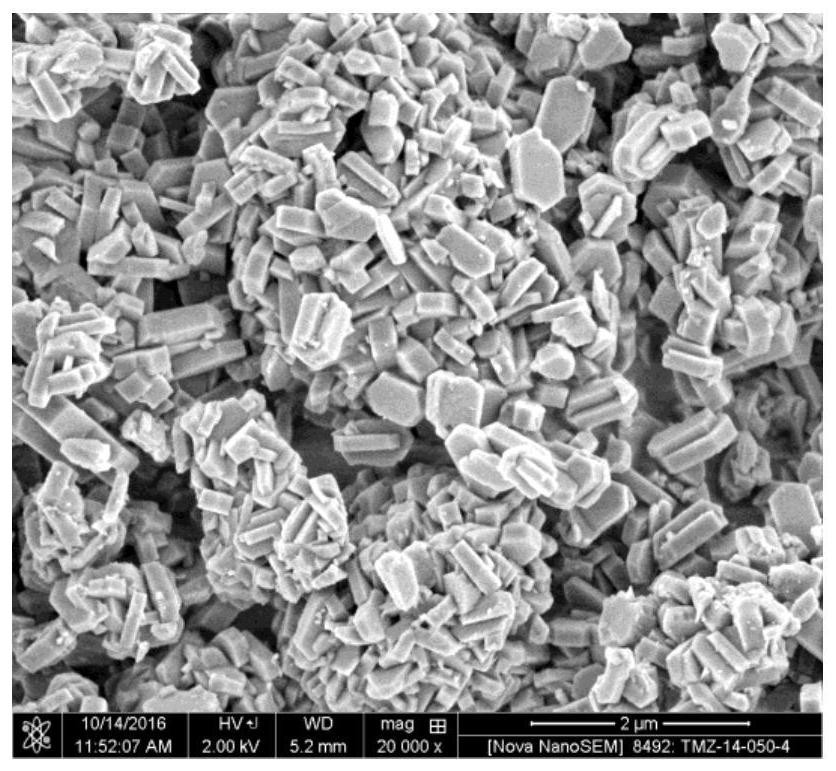

Embodiment 1

[0052] 2 grams of aluminum nitrate, 5 grams of ethylamine (M1) and 30 milliliters of water were stirred and dissolved to form solution A. After mixing 40 grams of tetraethyl orthosilicate and 50 grams of deionized water, they were stirred at room temperature for 5 hours to form solution B. Slowly add solution A, stir vigorously for 2 hours, add 1 wt% ZSM-5 seed crystal, stir for 1 hour, add 15 g of ammonia water (M2), and transfer the mixed system into a stainless steel crystallization kettle, and crystallize at 150°C for 72 hours. The XRD pattern of the obtained sample has characteristic diffraction peaks of ZSM-5 zeolite molecular sieve, and the thickness of the sheet molecular sieve in the SEM image is about 80 nm. Product SiO 2 / Al 2 O 3 The molar ratio is 63, Na + The content is 0.02%, and the yield of molecular sieve is 96%.

[0053] Weigh 20 grams of the above molecular sieve, 17 grams of alumina, 1 milliliter of concentrated nitric acid, 2.5 grams of ammonium molyb...

Embodiment 2

[0056] 1.5 grams of aluminum sulfate, 2 grams of diethylamine (M1) and 30 milliliters of water were stirred and dissolved to form solution A. After mixing 50 grams of silica sol (40%) and 10 grams of deionized water, they were stirred at room temperature for 0.5 hours to form solution B. B was slowly added to solution A, vigorously stirred for 2 hours, added with 2wt% ZSM-5 seed crystals and stirred for 1 hour, added 5 g of ethylamine (M2) solution, and the mixed system was transferred into a stainless steel crystallization kettle, and crystallized at 170 ° C for 24 hours. The XRD pattern of the obtained sample has characteristic diffraction peaks of ZSM-5 zeolite molecular sieve, and the thickness of the sheet molecular sieve in the SEM image is about 50 nm. Product SiO 2 / Al 2 O 3 The molar ratio is 147, Na + The content is 0.01%, and the yield of molecular sieve is 98%

[0057] Weigh 20 g of the above molecular sieve, 6 g of alumina, 0.5 ml of concentrated nitric acid,...

Embodiment 3

[0060] 5 grams of aluminum nitrate, 2 grams of ethylenediamine (M1) and 30 grams of deionized water were stirred and dissolved to form solution A, 40 grams of white carbon black was added to 50 grams of water and continued to stir to obtain solution B, and solution B was slowly added to solution A. , vigorously stirred for 2 hours, added 0.5wt% ZSM-5 seed crystals, stirred for 1 hour, and finally added 8 grams of ammonia water (M2), mixed well, moved into a stainless steel crystallization kettle, and crystallized at 130°C for 72 hours. The XRD pattern of the obtained sample has characteristic diffraction peaks of ZSM-5 zeolite molecular sieve, and the thickness of the sheet molecular sieve in the SEM image is about 30 nm. Product SiO 2 / Al 2 O 3 The molar ratio is 98, Na + The content is 0.01%, and the yield of molecular sieve is 97%

[0061] Weigh 20 grams of the above molecular sieve, 15 grams of silica sol (40%), 2 grams of ammonium molybdate, 1 gram of succulent powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com