Gypsum-based mechanically-jetted mortar and preparation method thereof, and gypsum-based mechanically-jetted decorative material slurry

A machine sprayed mortar and gypsum-based technology, which is applied in the field of gypsum-based machine-sprayed fabric slurry, gypsum-based machine-sprayed mortar and its preparation, can solve problems such as low cement-based mortar adhesion, peeling off of the plaster layer, and hollow walls , to achieve the effects of easy adjustment and control, delayed setting time, and good sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Weigh 100g of α high-strength gypsum (80 mesh) prepared from desulfurized gypsum, 10g of 32.5# ordinary Portland cement, 0.15g of hydroxypropyl methylcellulose ether, and high-efficiency gypsum-based retarder Retardan P (purchased from TRICOSAL, Germany) 0.01g, water reducer R+D Melflux ECO 5691F (purchased from BASF) 0.03g, redispersible latex powder 5010N (purchased from Wacker) 1g, grade II fly ash 5g, river sand 50g, (NH 4 ) 2 SO 4 0.05g, 90-100mm standard consistency of mixing water for mortar.

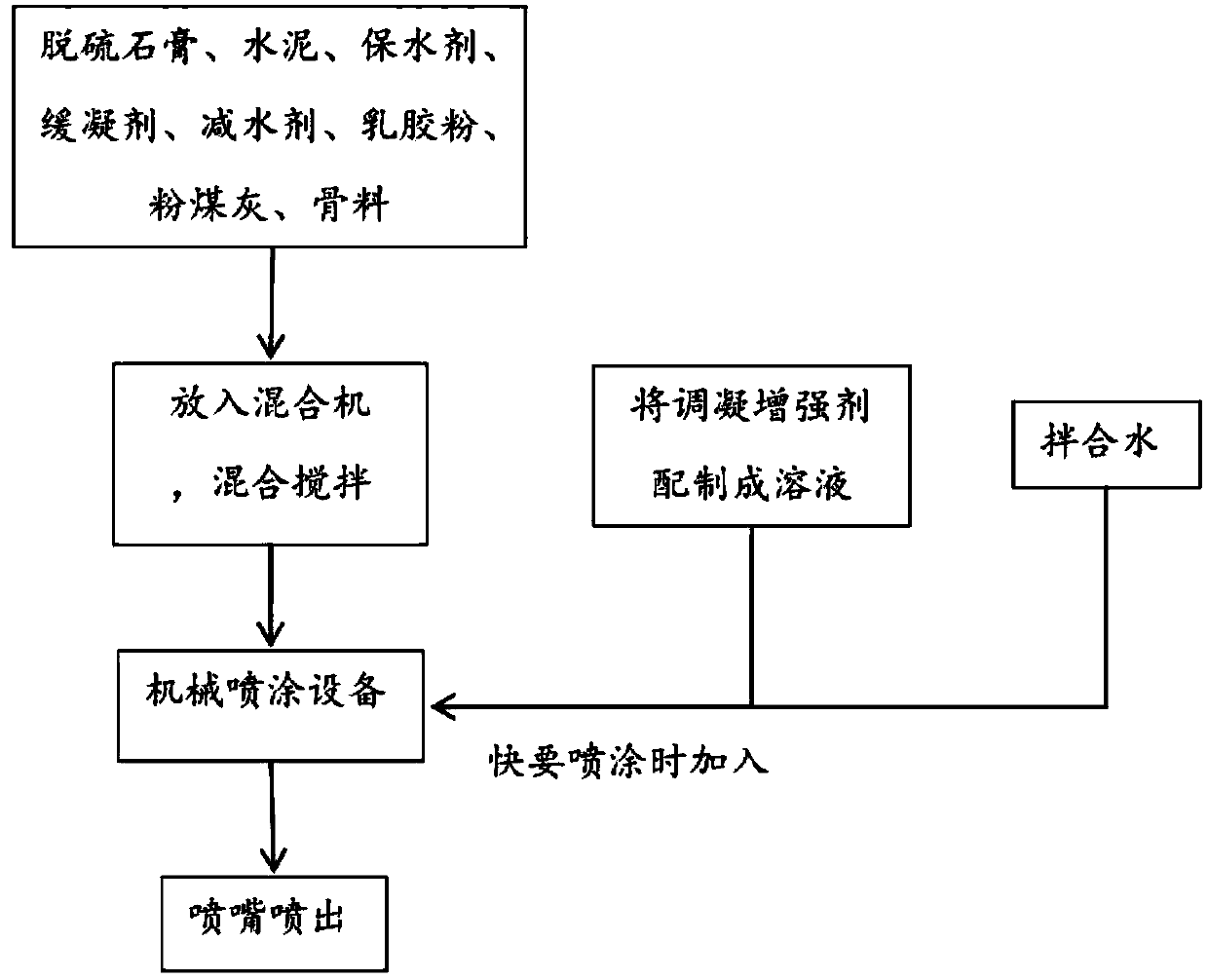

[0060] (2) During construction, put the above-mentioned premixed powder components (other substances except coagulation enhancer and mixing water) into the mixer, mix and stir for 2-3 minutes, and then put into the mechanical spraying equipment; (NH 4 ) 2 SO 4 Use an appropriate amount of mixing water to dissolve and prepare a coagulation enhancer solution; when spraying is about to be done, add the coagulation enhancer solution and the remaining mixing water to the prem...

Embodiment 2

[0063] (1) Weigh 100g of α high-strength gypsum (80 mesh) prepared from desulfurized gypsum, 20g of 32.5# ordinary Portland cement, 0.15g of hydroxypropyl methylcellulose ether, and high-efficiency gypsum-based retarder Retardan P (purchased from German TRICOSAL company) 0.01g, water reducing agent R+D Melflux ECO 5691F (purchased from BASF company) 0.05g, redispersible latex powder 5010N (purchased from Wacker) 1g, grade II fly ash 5g, river sand 60g, (NH 4 ) 2 SO 4 0.05g, 90-100mm standard consistency of mixing water for mortar.

[0064] (2) During construction, put the above-mentioned premixed powder components into the mixer and mix and stir for 2-3 minutes, and then put them into the mechanical spraying equipment; add the (NH 4 ) 2 SO 4 Use an appropriate amount of mixing water to dissolve and prepare the coagulation enhancer solution; when spraying, before the premixed powder passes through the nozzle of the mechanical spraying equipment, add the coagulation enhancer soluti...

Embodiment 3

[0067] (1) Weigh 100g of α high-strength gypsum (80 mesh) prepared from desulfurized gypsum, 30g of 42.5# ordinary Portland cement, 0.15g of hydroxypropyl methylcellulose ether, and high-efficiency gypsum-based retarder Retardan P (purchased from German TRICOSAL company) 0.01g, water reducing agent R+D Melflux ECO 5691F (purchased from BASF company) 0.04g, redispersible latex powder 5010N (purchased from Wacker) 1g, grade II fly ash 5g, river sand 80g, CaSO 4 ·2H 2 O 0.05g, mortar of 90-100mm standard consistency of water mixing water.

[0068] (2) During construction, put the above-mentioned premixed powder components into the mixer and mix and stir for 2-3 minutes, and then put them into the mechanical spraying equipment; put the CaSO 4 ·2H 2 O Dissolve with an appropriate amount of mixing water and prepare it into a coagulation enhancer solution; when spraying is about to be done, add the coagulation enhancer solution and the remaining mixing water to the premixed powder, mix e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com