Bonding layer and heat dissipation structure for heat dissipation of electronic device

A technology for electronic devices and heat dissipation structures, applied in the direction of non-polymer adhesive additives, electrical components, electrical equipment structural parts, etc., can solve problems such as short circuits of devices, and achieve the effect of preventing dimensional changes and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

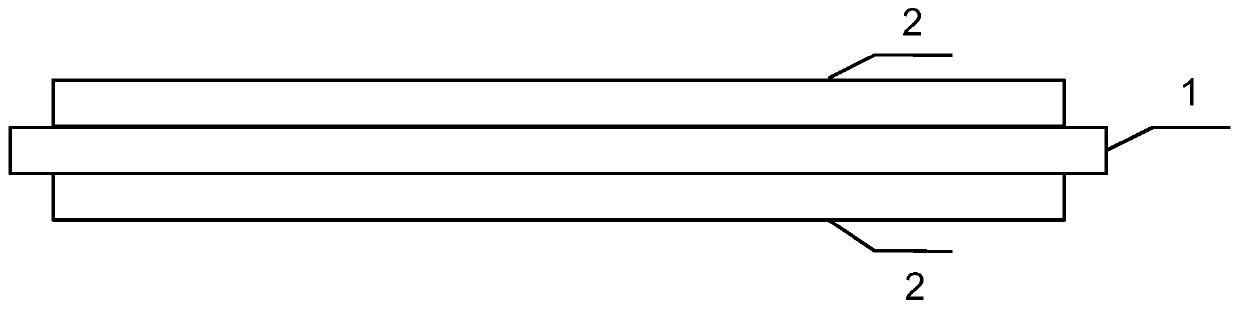

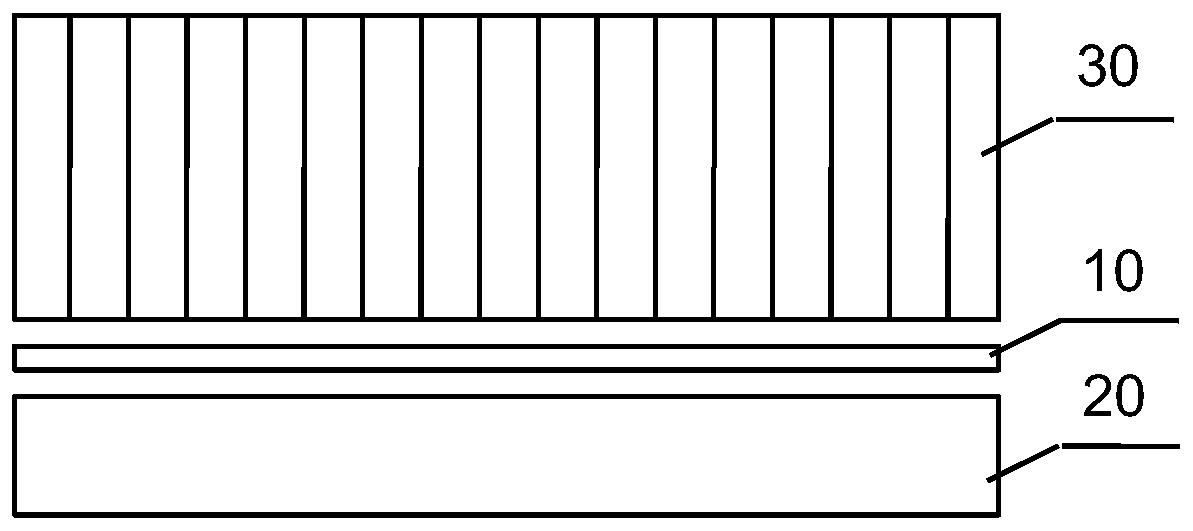

[0020] Please combine figure 1 As shown, a kind of adhesive layer for heat dissipation of electronic devices provided by the present invention comprises:

[0021] An intermediate support layer 1 made of PTFE microporous membrane, the thickness of the intermediate support layer 1 is between 5-20um, preferably 10um. as well as

[0022] One or more layers of heat-conducting and insulating coatings 2 are provided adjacent to both sides of the intermediate support layer 1 , and the thickness of the heat-conducting and insulating coating 2 is between 5-15 um, preferably 10 um. The thermally conductive and insulating coating 2 includes hexagonal boron nitride blended with a binder, and the content of the hexagonal boron nitride is between 30% and 100%. The hexagonal boron nitride has a layered structure similar to graphite, has go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com