Method for preparing Magneli-phase titanium oxide mesoporous surface

A titanium oxide and mesoporous technology, which is applied in the field of preparation of Magneli phase titanium oxide mesoporous surface, can solve the problems of poor bonding force of load substrates, secondary pollution of water body, small contact area, etc., so as to shorten the preparation cycle and reduce the The effect of high production cost and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Titanium oxide Ti with Magneli phase prepared under the discharge time of 40min and discharge power of 420W 4 o 7 Titanium mesh on a mesoporous surface.

[0032] Drop 4 mL of 0.1 mol / L nitric acid solution into 50 mL of deionized water, and stir thoroughly to obtain an electrolyte. Drop 10 mL of 0.1 mol / L nitric acid solution into 60 mL of deionized water, and stir well to obtain a buffer solution.

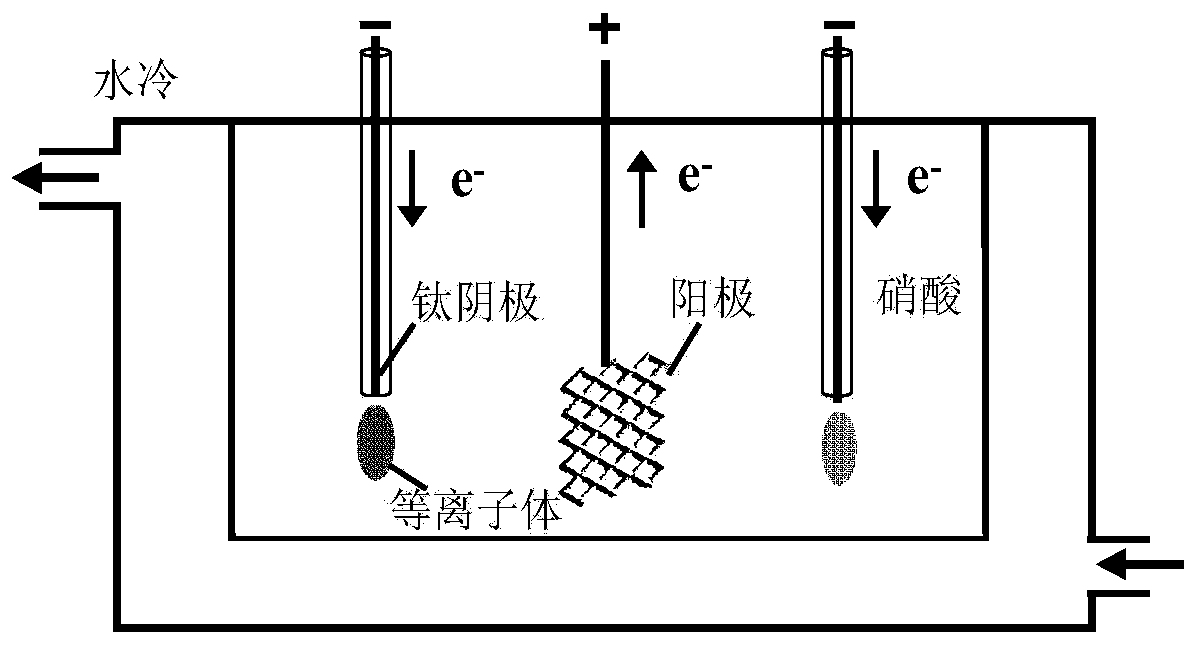

[0033] Such as figure 2 As shown, two titanium rod cathodes are symmetrically placed on both sides of the titanium mesh anode to form a parallel discharge system. The diameter of the two titanium rod cathodes used is 4mm and the length is 20cm. Put two titanium rod cathodes into the corundum tube, and only the conical tip part with a length of 0.8cm is not covered by the corundum tube. The specification of the titanium mesh anode used is 0.1*2*2cm 3 , the titanium grid hole size is 2*3mm 2 , the grid thickness is 1mm.

[0034] The electrolyte is poured into the elect...

Embodiment 2

[0037] Titanium oxide Ti with Magneli phase prepared under the discharge time of 60min and discharge power of 420W 4 o 7 Titanium mesh on a mesoporous surface.

[0038] Drop 4 mL of 0.1 mol / L nitric acid solution into 50 mL of deionized water, and stir thoroughly to obtain an electrolyte. Drop 10 mL of 0.1 mol / L nitric acid solution into 60 mL of deionized water, and stir well to obtain a buffer solution.

[0039] Such as figure 2 As shown, two titanium rod cathodes are symmetrically placed on both sides of the titanium mesh anode to form a parallel discharge system. The diameter of the two titanium rod cathodes used is 4mm and the length is 20cm. Put two titanium rod cathodes into the corundum tube, and only the conical tip part with a length of 0.8cm is not covered by the corundum tube. The specification of the titanium mesh anode used is 0.1*2*2cm 3 , the titanium grid hole size is 2*3mm 2 , the grid thickness is 1mm.

[0040] The electrolyte is poured into the elect...

Embodiment 3

[0043] Titanium oxide Ti with Magneli phase prepared under the discharge time of 80min and discharge power of 420W 4 o 7 Titanium mesh on a mesoporous surface.

[0044] Drop 4 mL of 0.1 mol / L nitric acid solution into 50 mL of deionized water, and stir thoroughly to obtain an electrolyte. Drop 10 mL of 0.1 mol / L nitric acid solution into 60 mL of deionized water, and stir well to obtain a buffer solution.

[0045] Such as figure 2 As shown, two titanium rod cathodes are symmetrically placed on both sides of the titanium mesh anode to form a parallel discharge system. The diameter of the two titanium rod cathodes used is 4mm and the length is 20cm. Put two titanium rod cathodes into the corundum tube, and only the conical tip part with a length of 0.8cm is not covered by the corundum tube. The specification of the titanium mesh anode used is 0.1*2*2cm 3 , the titanium grid hole size is 2*3mm 2 , the grid thickness is 1mm.

[0046] The electrolyte is poured into the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge power | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com