Catalyst composition for preparing low-carbon hydrocarbons from synthesis gas and application of catalyst composition

A catalyst and synthesis gas technology, applied in molecular sieve catalysts, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as high olefin ratio, high single-pass conversion rate, and low CO conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

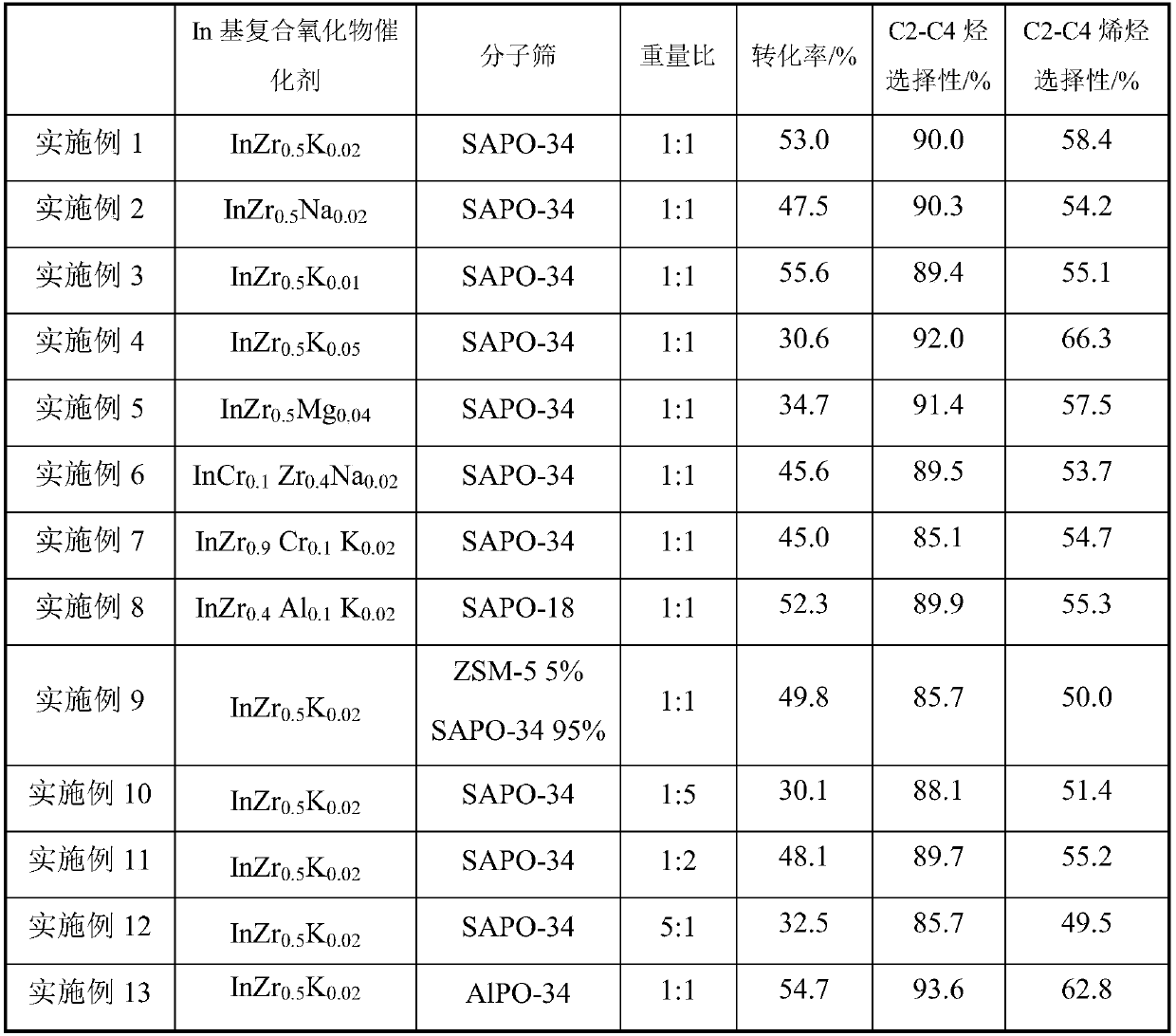

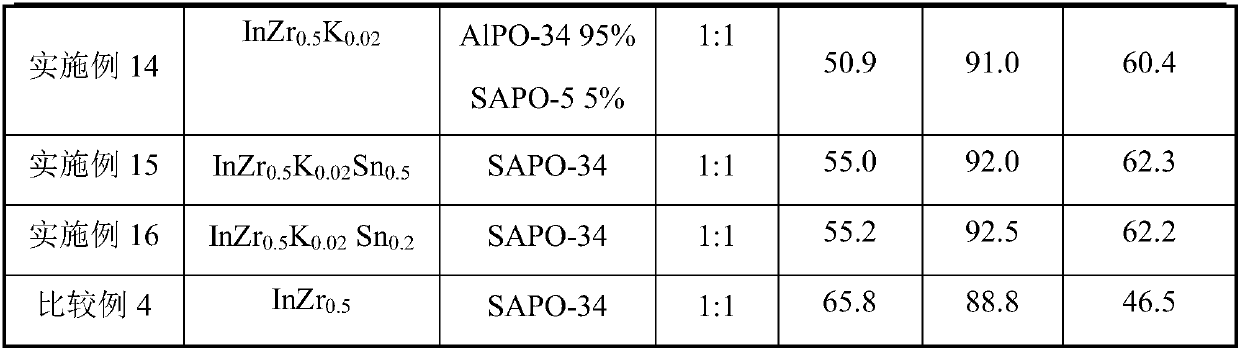

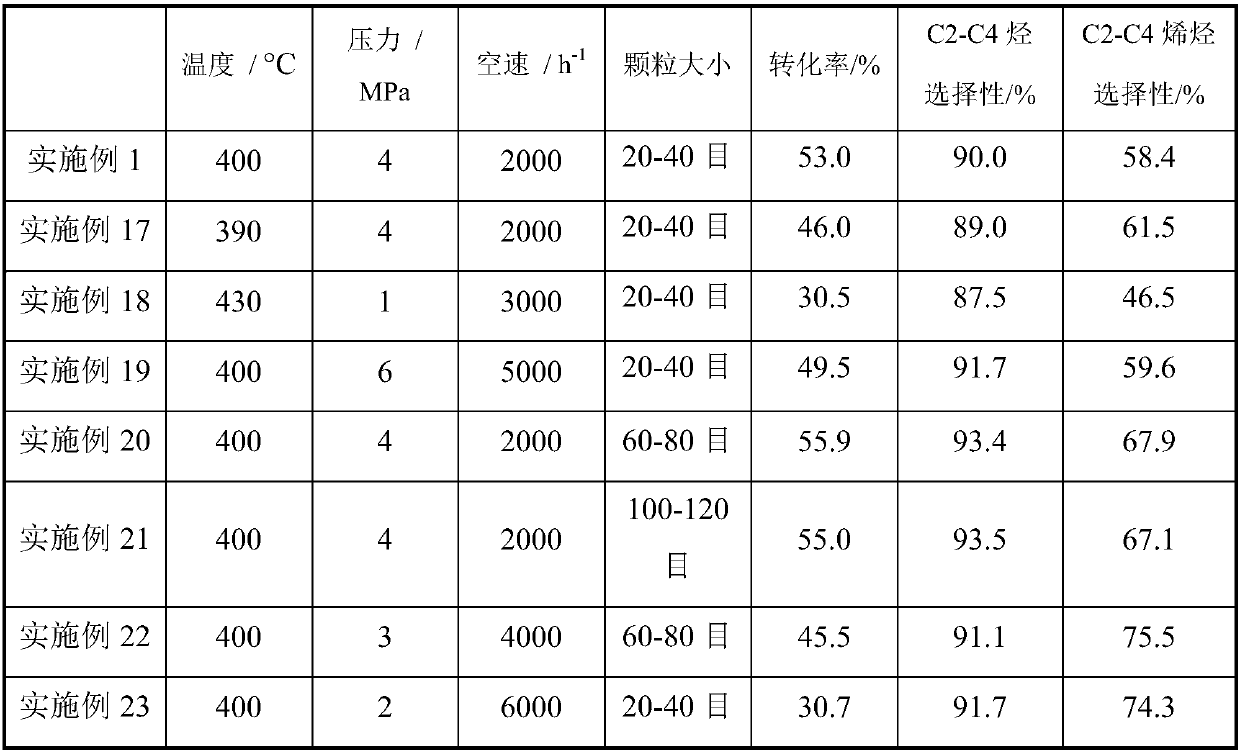

Examples

Embodiment 1

[0036] InZr 0.5 K 0.02 Catalyst is prepared as follows:

[0037] 25.46g In(NO 3 ) 3 4.5H 2 O and 14.32g Zr(NO 3 ) 4 ·5H 2 Dissolve O in 200ml of water, stir well, and continue stirring for 10 minutes after all dissolve. 14.4g (NH 4 )2 CO 3 Dissolve in 150ml of water and stir until completely dissolved. Drop the two solutions into 20ml of water at the same time, and the ratio of dropping speed is 4:3. Keep stirring while dropping, and keep the solution temperature at 70°C, continue to stir for 3 hours after the dropwise addition, filter the obtained precipitate and wash it with water until neutral, put it in an oven at 80°C for 12 hours, and break it to obtain a powder solid , and then ground and mixed with 107 mg of anhydrous potassium carbonate, and then calcined at 500° C. for 1 hour.

[0038] After the calcined catalyst is crushed, it is pressed into tablets to 20-40 mesh and mixed evenly with SAPO-34 of the same size and quality.

[0039] Catalyst evaluations ...

Embodiment 2

[0041] InZr 0.5 Na 0.02 Catalyst is prepared as follows:

[0042] 25.46g In(NO 3 ) 3 4.5H 2 O and 14.32g Zr(NO 3 ) 4 ·5H 2 Dissolve O in 200ml of water, stir well, and continue stirring for 10 minutes after all dissolve. 14.4g (NH 4 ) 2 CO 3 Dissolve in 150ml of water and stir until completely dissolved. Drop the two solutions into 20ml of water at the same time, and the ratio of dropping speed is 4:3. Keep stirring while dropping, and keep the solution temperature at 70°C, continue to stir for 3 hours after the dropwise addition, filter the obtained precipitate and wash it with water until neutral, put it in an oven at 80°C for 12 hours, and break it to obtain a powder solid , and then ground and mixed with 82mg of anhydrous sodium carbonate, and then calcined at 500°C for 1 hour.

[0043] After the calcined catalyst is crushed, it is pressed into tablets to 20-40 mesh and mixed evenly with SAPO-34 of the same size and quality.

[0044] Catalyst evaluations were...

Embodiment 3

[0046] InZr 0.5 K 0.01 Catalyst is prepared as follows:

[0047] 25.46g In(NO 3 ) 3 4.5H 2 O and 14.32g Zr(NO 3 ) 4 ·5H 2 Dissolve O in 200ml of water, stir well, and continue stirring for 10 minutes after all dissolve. 14.4g (NH 4 ) 2 CO 3 Dissolve in 150ml of water and stir until completely dissolved. Drop the two solutions into 20ml of water at the same time, and the ratio of dropping speed is 4:3. Keep stirring while dropping, and keep the solution temperature at 70°C, continue to stir for 3 hours after the dropwise addition, filter the obtained precipitate and wash it with water until neutral, put it in an oven at 80°C for 12 hours, and break it to obtain a powder solid , and then ground and mixed with 54 mg of anhydrous potassium carbonate, and then calcined at 500° C. for 1 hour.

[0048] After the calcined catalyst is crushed, it is pressed into tablets to 20-40 mesh and mixed evenly with SAPO-34 of the same size and quality.

[0049] Catalyst evaluations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com