A clamping method for CNC machining of six-sided machining parts

A surface processing and part installation technology, applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems that have not yet appeared, affect the quality and efficiency of parts processing, and difficult to control the processing of parts, and reduce The effect of a large number of tool marks, improving processing efficiency and reducing the number of clamping times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

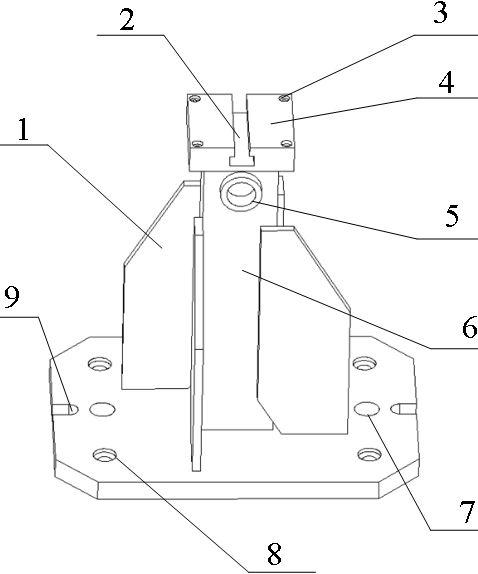

[0036] A kind of numerical control machining clamping method of six-sided machining parts, such as Figure 5 As shown, using part tooling for clamping mainly includes the following steps:

[0037] Step S200: install the tool inspection block in the tool inspection block placement hole 5 of the part tooling, and inspect the tool through the tool inspection block;

[0038] Step S300: After passing the inspection, process one or more of the upper, left, right, front and rear five surfaces of the part on the vertical-horizontal conversion machine tool;

[0039] Step S400: After the processing is completed, the part and the inspection block are removed; the processed surface of the part is clamped by the pressing support block and the pressing mechanism of the part tooling, and the part is pressed on the tooling installation positioning plate;

[0040] Step S500: Then repeat step S100, and process the first clamping surface and other unprocessed surfaces of the part.

[0041] Dur...

Embodiment 2

[0044] This embodiment is further optimized on the basis of Embodiment 1, and also includes step S100: threading the part blank on the tooling installation positioning plate of the part tooling; in the step S100, on the part blank, according to the blank margin, select Measure more planes and make 4 pressing holes, and tap the thread. The aperture of the pressing holes is consistent with the aperture of the screw hole on the positioning plate of the tooling.

[0045] In the present invention, screws are tightened upwards from the bottom of the mounting screw hole 3, and the blanks of the six-sided processing parts to be processed are locked on the installation positioning plate. The hindrance of processing facilitates the normal processing, so that the subsequent processing can be completed in one step, and the processing accuracy is increased. The reverse clamping of the screw can reduce the interference of the screw to the CNC machining process under the normal clamping metho...

Embodiment 3

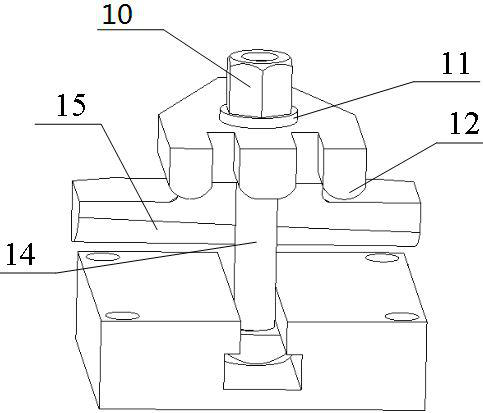

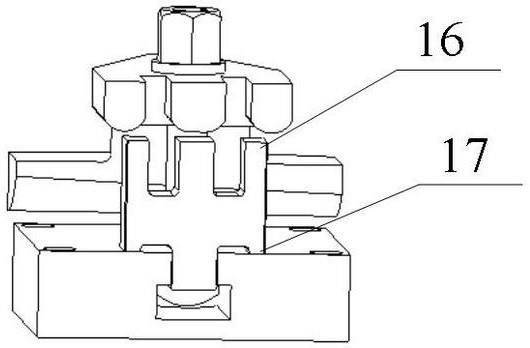

[0048] This embodiment is further optimized on the basis of embodiment 2, as Figure 4 As shown, in the step S200, the tool reserved by the program passes through the tool length verification plane 18 of the tool inspection block to check whether the tool length is correct; the tool reserved by the program passes the bottom tooth of the tool inspection block to verify the curved surface Verify the bottom tooth and radius of the tool; after the processing in step S500 is completed, remove the tool inspection block, parts and pressing mechanism.

[0049] In the present invention, during use, the installation head 20 of the knife inspection block is installed in the placement hole 5 of the knife inspection block, and the knife passes the knife length verification plane 18 through the program to reserve a margin to check whether the knife length is correct; The measuring tool passes through the tool bottom tooth verification curved surface 19 to verify the bottom tooth and radius ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com