Preparation method of environment-friendly type composite modified asphalt

A composite modified asphalt, environmentally friendly technology, applied in building thermal insulation materials, building components, construction and other directions, can solve the problems of low rubber powder content, high asphalt cost, long processing process, etc., achieve good UV resistance, reduce water Pollution, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

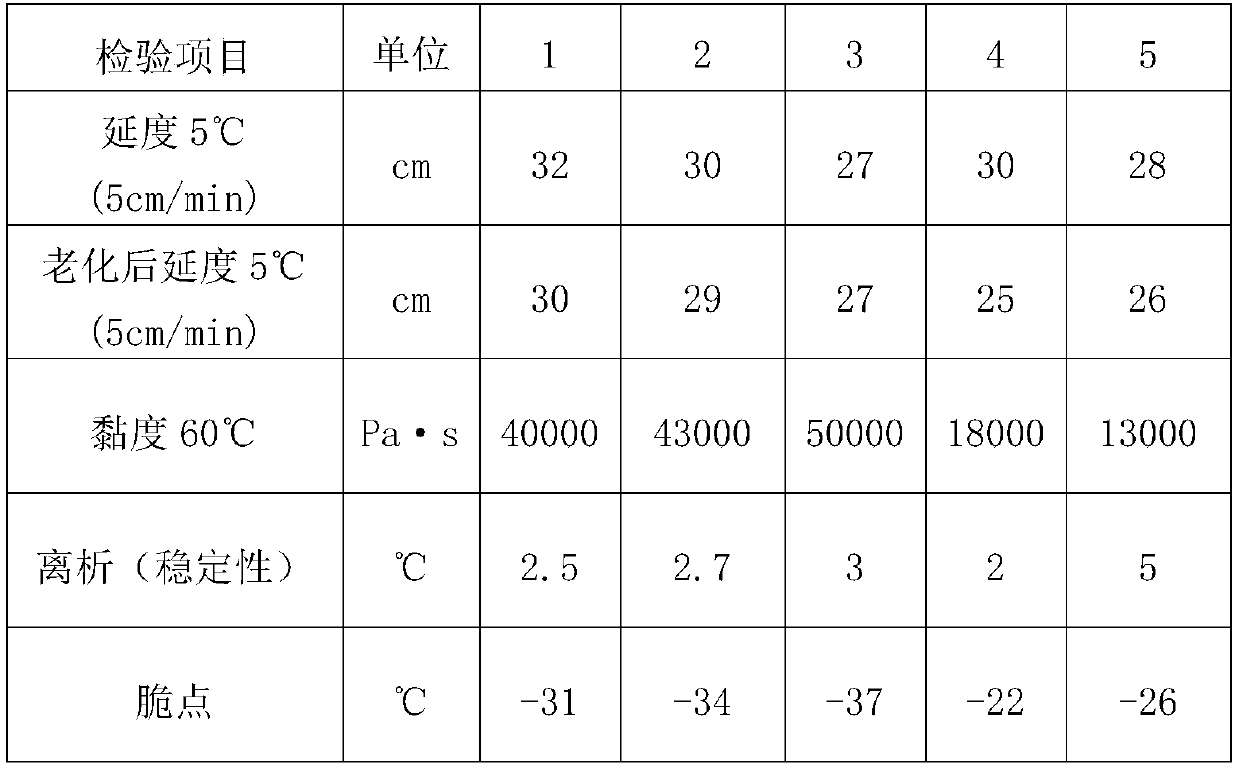

Examples

preparation example Construction

[0033] A preparation method of environment-friendly composite modified asphalt, comprising three steps of preparation of instant adhesive masterbatch, preparation of instant adhesive mother liquor and co-crosslinking development of instant adhesive mother liquor and SBS, specifically:

[0034] Step 1: Preparation of instant rubber masterbatch: Desulfurize the tire rubber powder through a multi-stage screw continuous desulfurization process, then extrude the screw and granulate to obtain instant rubber masterbatch;

[0035] Step 2: Preparation of instant adhesive mother liquor: mix the instant adhesive masterbatch and base asphalt obtained in step 1 in a mass ratio of 32 / 68-65 / 35, and let the instant adhesive masterbatch be in the base asphalt at a temperature of 160-170°C Soak and develop for 0.5-1.5 hours, then cut in high-speed shearing equipment for 15-30 minutes, so that the rubber powder is micro-nano dispersed, and the instant glue mother solution is obtained;

[0036]St...

Embodiment 1

[0049] (1) Mix 30 parts by mass of instant adhesive masterbatch and 70 parts by mass of AH70# base asphalt in a pre-development tank, and swell and develop for 1 hour at a temperature of 160°C.

[0050] (2) The mixture in step (1) was sheared at high speed for 15 minutes by a high-speed shearing machine to obtain the mother liquor of instant glue.

[0051] (3) the instant glue mother liquor that step (2) obtains and SBS modifying agent are mixed by the mass ratio of 96 / 4, and SBS modifying agent is the star SBS (mass average molecular weight is 300,000) purchased from Yueyang Petrochemical, in Shear on a high-speed shear for 30 minutes, the shear rate is 3000r / min, and the temperature is controlled at 170°C.

[0052] (4) Add 0.5%wt (based on the total mass of the product) of sulfur-based crosslinking stabilizer as a co-crosslinking stabilizer, stir for 60 minutes, and develop an environmentally friendly composite modified asphalt after sufficient stirring and development, No. ...

Embodiment 2

[0054] (1) Mix 40 parts by mass of instant adhesive masterbatch and 60 parts by mass of AH70# base asphalt in a pre-development tank, and swell and develop for 1 hour at a temperature of 160°C.

[0055] (2) The mixture in step (1) was sheared at high speed for 25 minutes by a high-speed shearing machine to obtain the mother liquor of instant glue.

[0056] (3) the instant glue mother liquor that step (2) obtains and SBS modifying agent are mixed by the mass ratio of 96 / 4, and SBS modifying agent is the star SBS (mass average molecular weight is 300,000) purchased from Yueyang Petrochemical, in Shear on a high-speed shear for 30 minutes, the shear rate is 3500 r / min, and the temperature is controlled at 170°C.

[0057] (4) Add 0.6%wt (based on the total mass of the product) epoxy rubber crosslinking stabilizer as a co-crosslinking stabilizer, stir for 120min, and develop an environmentally friendly composite modified asphalt after sufficient stirring and development, No. 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com