Self-repairing resin, coating and film as well as preparation method and application of film

A self-healing, resin technology, applied in the field of coatings, can solve the problems of limited number of repairs, short service life, and limited use of coatings, and achieve the effect of stable anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

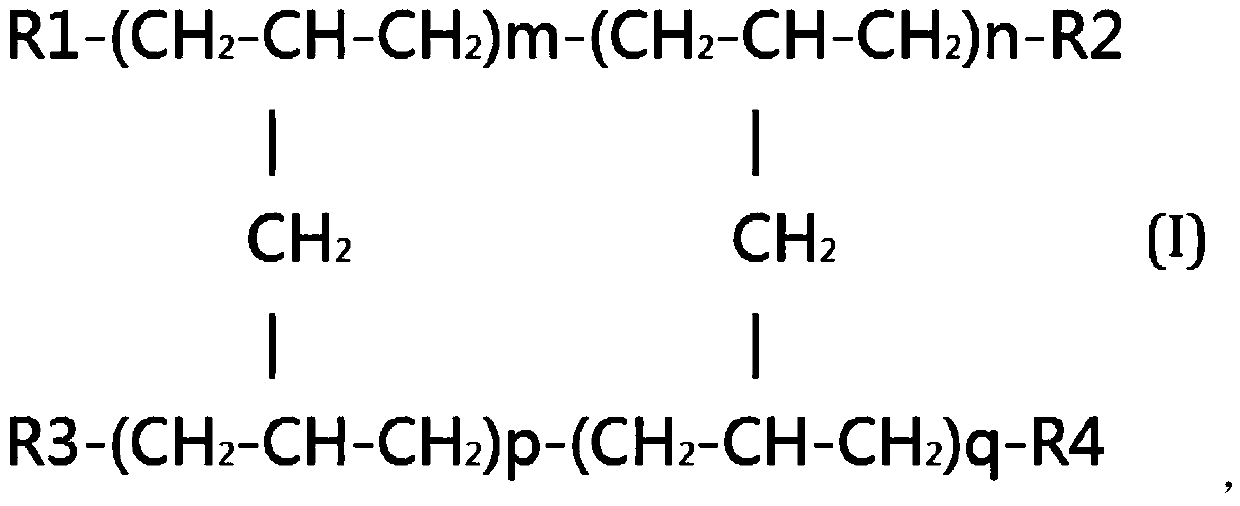

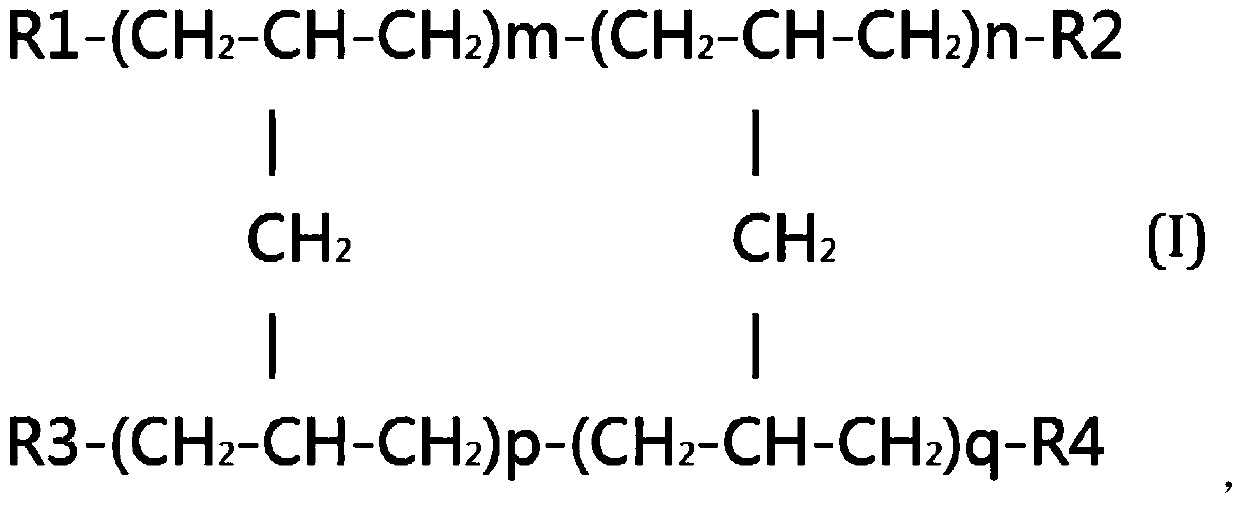

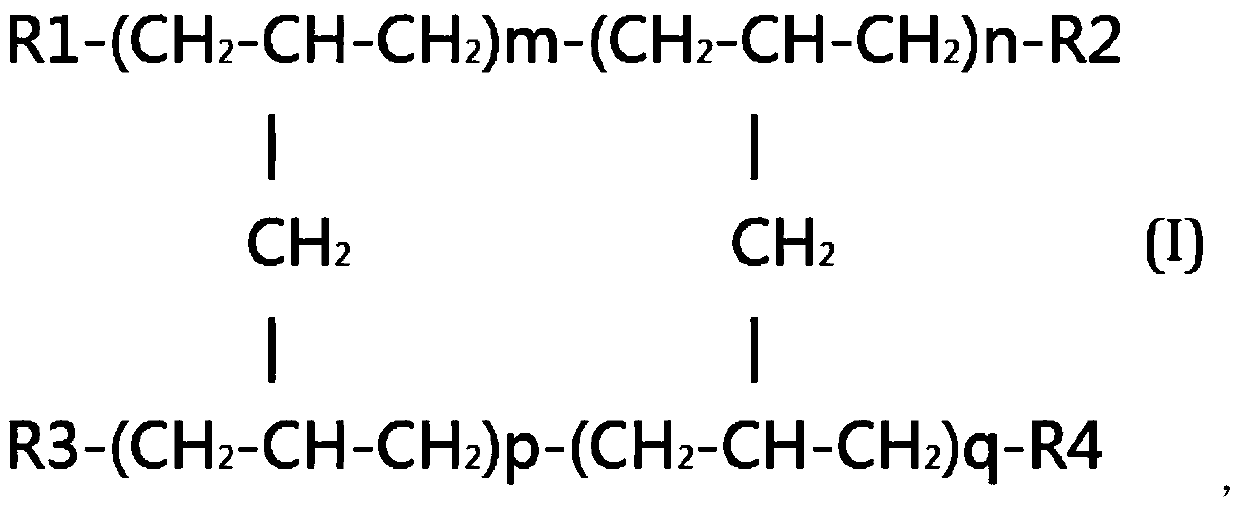

[0044] This embodiment relates to a UV-curable self-healing anti-fouling film, including a base material and a UV-curable self-healing anti-fouling resin laid on the base material; in parts by weight, the UV-curable self-healing anti-fouling resin includes The following components: 40 parts of oligomers described in general formula (I), 3 parts of curing agent, 2 parts of antifouling additives, 55 parts of solvent;

[0045] The functional groups R1, R2, R3 and R4 in the oligomer are all acryloyloxy groups, and m, n, p and q are natural numbers between 20 and 30 respectively;

[0046] The curing agent adopts 1-hydroxy-cyclohexyl-phenyl ketone;

[0047] The antifouling auxiliary agent adopts DAC-HP of Daikin Company;

[0048] Described solvent is the mixture of ethyl acetate and butanone;

[0049] The base material adopts TPU film.

[0050] This embodiment relates to the preparation method of the above-mentioned UV-cured self-healing antifouling film, which includes the follo...

Embodiment 2

[0055] This embodiment relates to a UV-curable self-healing anti-fouling film, including a base material and a UV-curable self-healing anti-fouling resin laid on the base material; in parts by weight, the UV-curable self-healing anti-fouling resin includes The following components: 35 parts of oligomers described in general formula (I), 5 parts of curing agent, 2 parts of antifouling additives, 58 parts of solvent;

[0056] The functional groups R1 and R2 in the oligomer are acryloyloxy groups, R3 and R4 are allyl groups, and m, n, p and q are natural numbers between 150 and 180, respectively;

[0057] The curing agent adopts 2,4,6-trimethylbenzoyl-diphenylphosphine oxide;

[0058] The antifouling auxiliary agent adopts KY-1203 of Shin-Etsu Company;

[0059] Described solvent is the mixture of propylene glycol methyl ether and butanone;

[0060] The base material adopts PET film.

[0061] This embodiment relates to the preparation method of the above-mentioned UV-cured self-h...

Embodiment 3

[0066] This embodiment relates to a heat-cured self-healing anti-fouling film, including a substrate and a heat-cured self-healing anti-fouling resin laid on the substrate; in parts by weight, the heat-curing self-healing anti-fouling resin includes the following components : 50 parts of oligomers described in general formula (I), 10 parts of curing agent, 2 parts of antifouling additives, 38 parts of solvent;

[0067] The functional groups R1, R2, R3 and R4 in the oligomer are all epoxy groups, and m, n, p and q are natural numbers between 100 and 120 respectively;

[0068] Described curing agent adopts toluene diisocyanate;

[0069] The antifouling additive adopts BYK-377 of BYK;

[0070] Described solvent is the mixture of ethyl acetate and butyl acetate;

[0071] The base material adopts TPU film.

[0072] This embodiment relates to the preparation method of the above-mentioned heat-cured self-healing antifouling film, comprising the following steps:

[0073] 1) Coat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com