Method for preparing strontium silicate powder material by using strontium hydroxide and silica fume

A technology of strontium hydroxide and powder materials, which is applied in chemical instruments and methods, luminescent materials, petroleum industry and other directions, can solve the problems of reduced luminous brightness, unfavorable energy saving and environmental protection, and high preparation temperature, and achieves improved high-temperature friction performance and low cost. , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

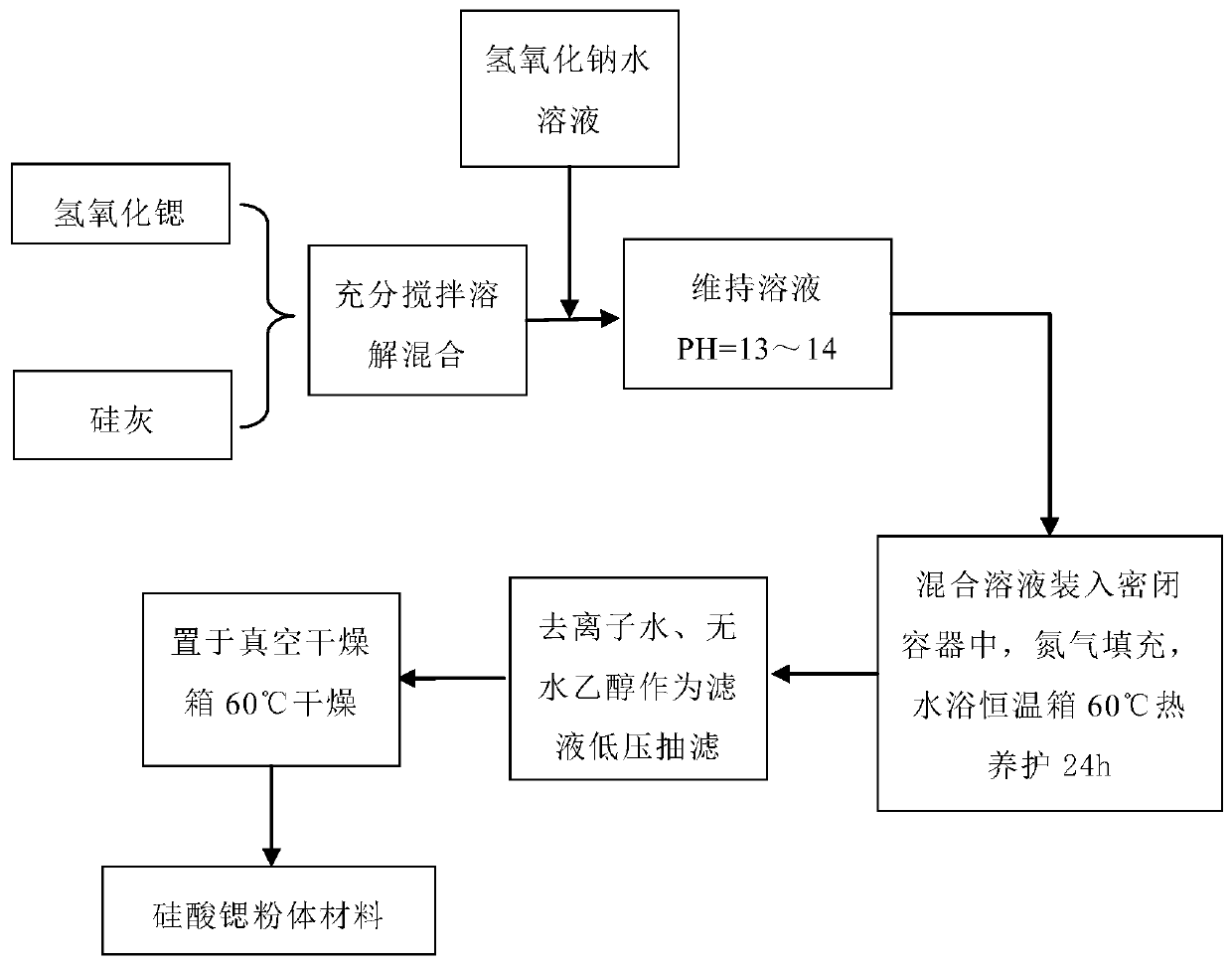

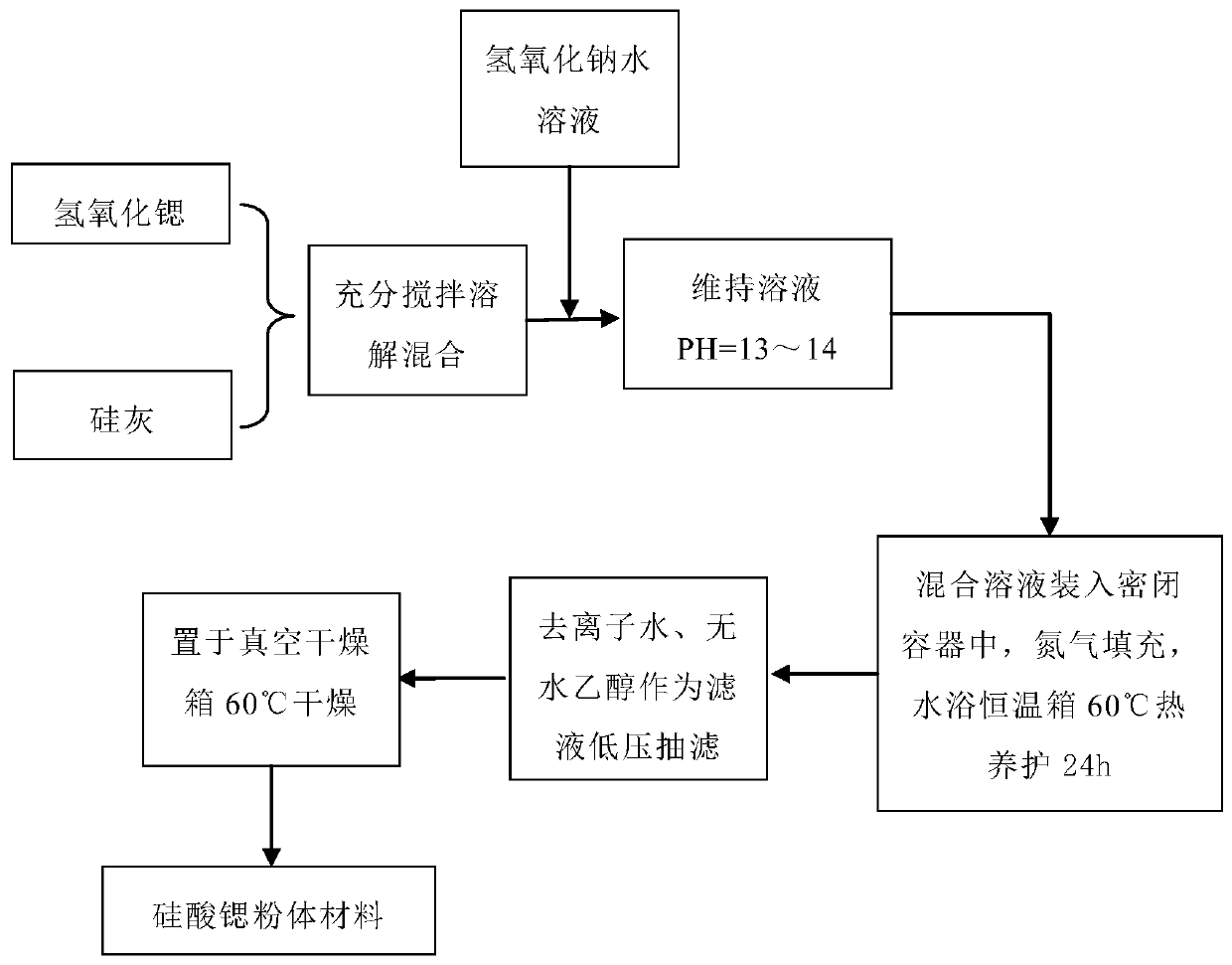

[0018] refer to figure 1 , the present invention utilizes strontium hydroxide and silica fume to prepare the method for strontium silicate powder material, comprises the steps:

[0019] (1) According to the molar ratio Sr:Si=1:1, C(NaOH)=1mol / L, weigh m(Sr(OH) 2 )=121.6g, m(SF)=60g, m(NaOH)=20g, m(H 2 (0) = 300 g.

[0020] (2) Place strontium hydroxide in water, fully stir and dissolve with a glass rod;

[0021] (3) Put the silica fume in water and fully stir and dissolve it with a glass rod;

[0022] (4) Sodium hydroxide is placed in water, fully stirred and dissolved with a glass rod;

[0023] (5) Mix the two solutions prepared in steps (2) and (3), stir well, seal and let stand at room temperature for 1 hour.

[0024] (6) Use a pH meter to measure the solution after standing in step (5) for 1 hour. If the pH is less than 13, add the sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com