CNT-containing aqueous lithium battery paste and preparation method thereof

A lithium battery and slurry technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as damage balance, substandard secondary particles, and affecting processing performance, so as to solve the dispersion problem, simplify the preparation method, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

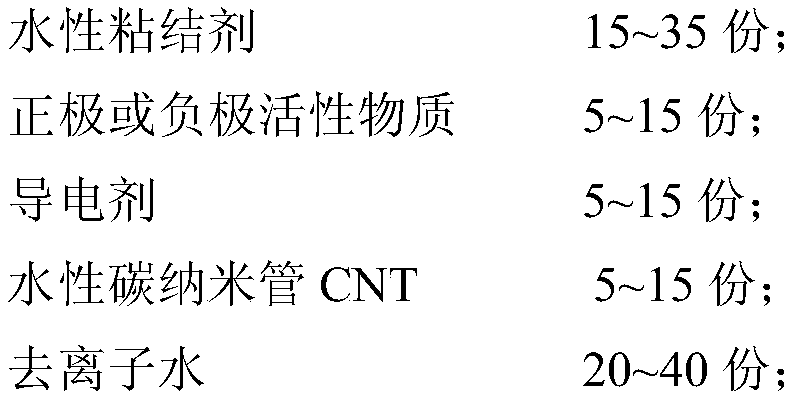

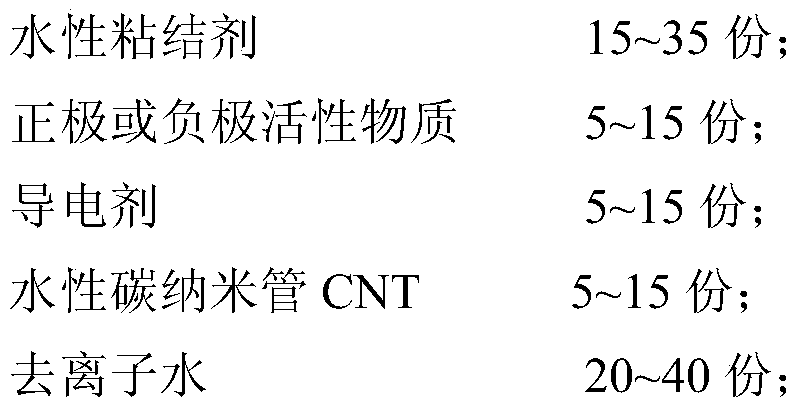

[0038] A positive electrode aqueous lithium battery slurry containing CNT, comprising the following components in parts by mass: 15 parts of polyacrylate; LiFePO 4 5 parts; 5 parts of Super-P conductive agent; 5 parts of water-based CNT; 20 parts of deionized water.

[0039] The specific preparation method of the above-mentioned lithium battery slurry is (carried out in a double planetary vacuum mixer):

[0040] ① Stir 70% of polyacrylate and deionized water for 20 minutes in an environment with a vacuum degree of -0.08mpa;

[0041] ② Add Super-P conductive agent and stir at a low speed. After the Super-P conductive agent is fully wetted, stir for 60 minutes at a revolution speed of 70r / min, a dispersion speed of 3000r / min, and a vacuum of -0.08mpa;

[0042] ③Add LiFePO 4 , 20% of deionized water, and stirred for 120min at a revolution speed of 70r / min, a dispersion speed of 3000r / min, and a vacuum of -0.08mpa;

[0043]④ Add the CNT dispersion (the CNT dispersion is the wa...

Embodiment 2

[0047] A positive electrode aqueous lithium battery slurry containing CNT, comprising the following components in parts by mass: 35 parts of polyacrylate; 15 parts of LMO; 15 parts of KS-6 conductive agent; 15 parts of aqueous CNT; 40 parts of deionized water.

[0048] The concrete preparation method of above-mentioned lithium battery slurry is:

[0049] ① Stir 85% of polyacrylate and deionized water for 30 minutes in an environment with a vacuum degree of -0.07mpa;

[0050] ② Add KS-6 conductive agent and stir at a low speed. After the KS-6 conductive agent is fully wetted, stir for 120 minutes under the conditions of revolution speed 90r / min, dispersion speed 4000r / min, and vacuum degree -0.07mpa;

[0051] ③Add 10% of LMO and deionized water, and stir for 180min under the conditions of revolution speed of 80r / min, dispersion speed of 4000r / min, and vacuum degree of -0.07mpa;

[0052] ④ Add the CNT dispersion (the CNT dispersion is the water-based slurry of the model LB200-5...

Embodiment 3

[0056] A positive electrode aqueous lithium battery slurry containing CNT, comprising the following components in parts by mass: 20 parts of polyacrylate; 10 parts of LNCM; 10 parts of Super-P conductive agent; 10 parts of aqueous CNT; 30 parts of deionized water.

[0057] The concrete preparation method of above-mentioned lithium battery slurry is:

[0058] ① Stir 80% of polyacrylate and deionized water for 25 minutes in an environment with a vacuum degree of -0.09mpa;

[0059] ② Add the Super-P conductive agent and stir at a low speed. After the Super-P conductive agent is fully wetted, stir for 90 minutes at a revolution speed of 80r / min, a dispersion speed of 3500r / min, and a vacuum of -0.09mpa;

[0060] ③ Add 20% of LNCM and deionized water, and stir for 150 minutes under the conditions of revolution speed of 75r / min, dispersion speed of 3500r / min, and vacuum degree of -0.09mpa;

[0061] ④ Add the CNT dispersion (the CNT dispersion is the water-based slurry of the model ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com