Ultrafine fly ash and preparation method thereof

A technology of ultra-fine fly ash and coal ash, which is applied in cement production and other directions, can solve the problems of rising raw material prices, environmental pollution, and supply reduction, and achieve stable cement quality performance, reduce production costs, and reduce usage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

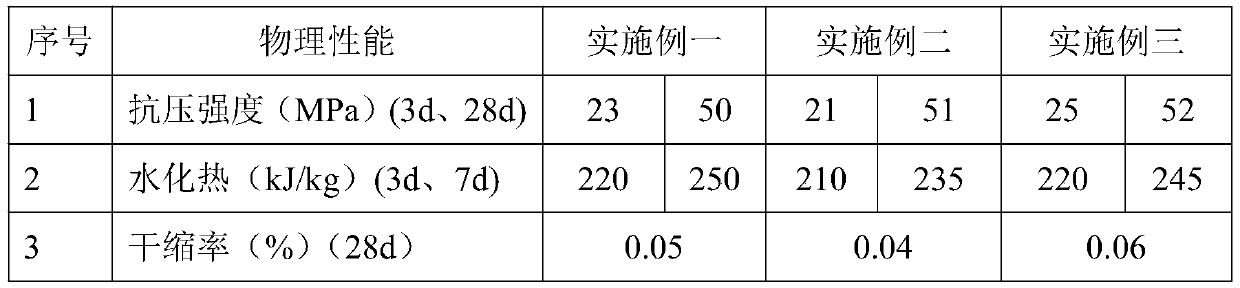

Examples

Embodiment 1

[0021] A kind of superfine fly ash and preparation method thereof, raw material composition and ratio (by 100kg as unit):

[0022] (1) Take 44% dry fly ash, 25% steel slag, 2% lime, 1% defoamer, 20% waste sand, 3% waste gypsum, and 5% slag.

[0023] (2) Crush the waste sand and waste gypsum to less than or equal to 4mm, store them in the shed, and age them for two weeks to balance their physical properties.

[0024] (3) Carry out magnetic separation treatment on dry fly ash, waste sand, steel slag and furnace slag respectively to remove iron

[0025] (4) Mix dry fly ash, steel slag, lime, waste sand, waste gypsum, and slag uniformly by weight, add water and mix for 3 hours, add additives and mix for 2 hours, then feed put into the grinding system for grinding treatment for 3 hours, and then perform dehydration treatment, and control the moisture content within the range of ≤4wt%.

[0026] (5) After the dehydration is completed, stop the machine and pour out the mixture to ob...

Embodiment 2

[0028] A kind of superfine fly ash and preparation method thereof, raw material composition and ratio (by 100kg as unit):

[0029] (1) Take 44% dry fly ash, 25% steel slag, 2% lime, 1% defoamer, 20% waste sand, 3% waste gypsum, and 5% slag.

[0030] (2) Crush the waste sand and waste gypsum to less than or equal to 4mm, store them in the shed, and age them for two weeks to balance their physical properties.

[0031] (3) The dry fly ash, waste sand, steel slag, and furnace slag are subjected to magnetic separation treatment to remove iron to balance their physical properties.

[0032] (4) Mix dry fly ash, steel slag, lime, waste sand, waste gypsum, and slag uniformly by weight, add water and mix for 4 hours, add additives and mix for 3 hours, and then feed Put it into the grinding system for grinding treatment for 1.5 hours, and then perform dehydration treatment, and control the moisture content within the range of ≤4wt%.

[0033] (5) After the dehydration is completed, stop...

Embodiment 3

[0035] A kind of superfine fly ash and preparation method thereof, raw material composition and ratio (by 100kg as unit):

[0036] (1) Take 44% dry fly ash, 25% steel slag, 2% lime, 1% defoamer, 20% waste sand, 3% waste gypsum, and 5% slag.

[0037] (2) Crush the waste sand and waste gypsum to less than or equal to 4mm, and store them in the shed respectively, and stale for two weeks to balance their physical properties.

[0038] (3) Carry out magnetic separation treatment on dry fly ash, waste sand, steel slag and furnace slag respectively to remove iron

[0039] (4) Mix dry fly ash, steel slag, lime, waste sand, waste gypsum, and slag uniformly by weight, add water and mix for 5 hours, add additives and mix for 4 hours, and then feed put into the grinding system for grinding treatment for 2 hours, and then perform dehydration treatment, and control the moisture content within the range of ≤4wt%.

[0040] (5) After the dehydration is completed, stop the machine and pour out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com