Quick-drying high-gloss varnish of automobile refinishing paint and preparation method of varnish

A fast-drying technology for automotive refinish paint, applied in the field of coatings, can solve the problems of reducing repair paint repair efficiency, impact resistance and other performance damage, and achieve the effects of long pot life, improved performance, and improved catalytic speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composition of a kind of quick-drying repair varnish is expressed as follows:

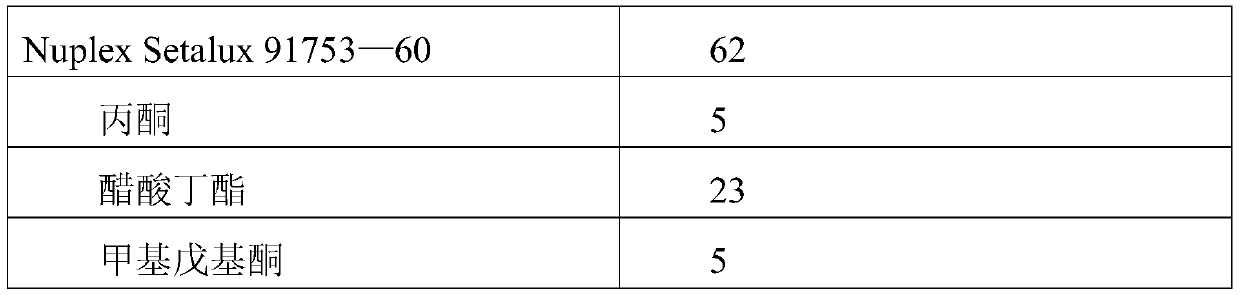

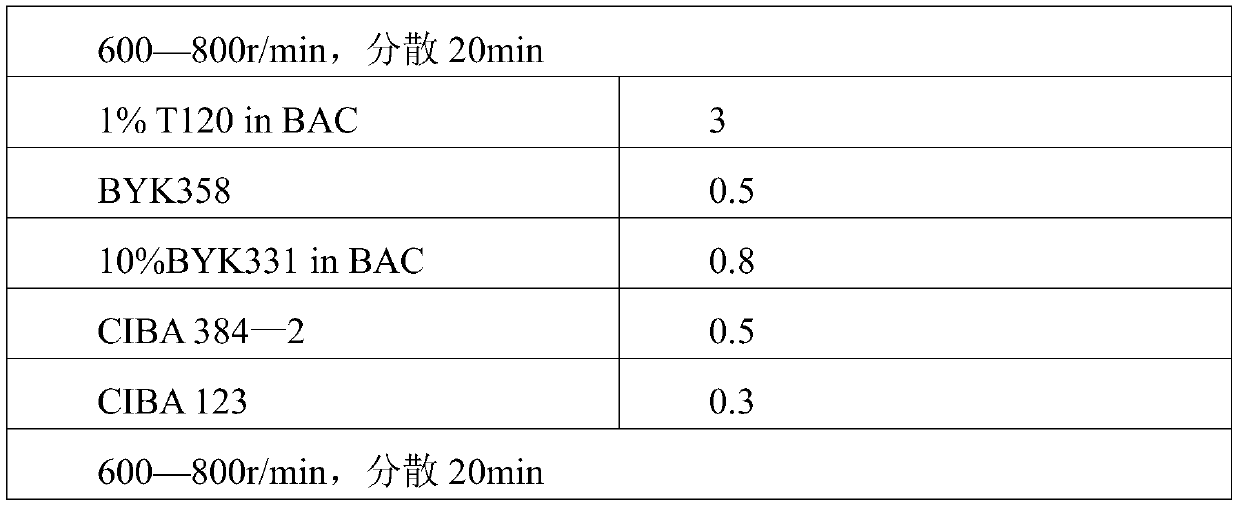

[0025] Component A

[0026]

[0027]

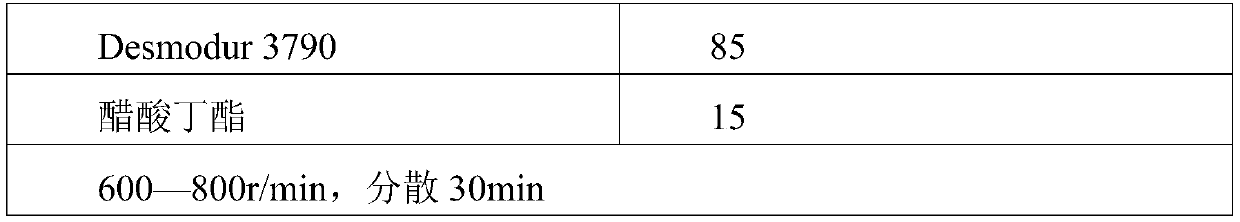

[0028] Component B

[0029]

[0030] Mix components A and B evenly at a mass ratio of 4:1, and dilute to spray viscosity with a thinner to obtain a water-based two-component high-gloss varnish.

[0031] (1) Spray the quick-drying repair varnish on a large A4 tin plate with a white background, measure its flexibility, dry hardness, impact resistance, polishing time, gloss, adhesion, and observe its plumpness.

[0032] (2) Spray the quick-drying repair varnish on the electrophoretic plate with a white background, and measure its water resistance, acid and alkali resistance, and gasoline resistance.

[0033] (3) Spray the quick-drying repair varnish on an aluminum plate with a white background, and measure its aging resistance.

[0034]

[0035]

[0036] It can be seen from the above test items that the quick-drying repair varnish has...

Embodiment 2

[0038] A preparation method of said quick-drying repair varnish comprises the following steps:

[0039] (1) Formula quantity by mass percentage: 60% acrylic resin Nuplex, 36% solvent butyl acetate, disperse with a disperser for 5-20 minutes, the dispersion speed is 600r / min, and then add 4% additives (mass ratio 3: 1:0.5 mixture of catalyst T120, leveling agent BYK 358 and UV-resistant additive CIBA 384-2), uniform dispersion, dispersion speed of 600r / min, dispersion time of 20 minutes, that is, quick-drying repair varnish A component ;

[0040] (2) Formula amount by mass percentage: 80% polyisocyanate curing agent, 20% solvent butyl acetate, carry out high-speed dispersion in a disperser, the dispersion speed is 600r / min, the dispersion time is 20 minutes, and the dispersion is uniform, that is, get Quick-drying repair varnish component B;

[0041] (3) Mix components A and B evenly at a mass ratio of 2:1 to obtain a quick-drying repair high-gloss varnish. The varnish can be...

Embodiment 3

[0043] A preparation method of said quick-drying repair varnish comprises the following steps:

[0044] (1) Formula amount by mass percentage: 55% acrylic resin Nuplex, 35% solvent butyl acetate, disperse with a disperser for 20 minutes, the dispersion speed is 600-800r / min, and then add 5% additives (mass ratio 3: 2:1 mixture of catalyst T120, leveling agent BYK 358 and UV-resistant additive CIBA 384-2), uniform dispersion, dispersion speed of 800r / min, dispersion time of 30 minutes, that is, quick-drying repair varnish A component ;

[0045] (2) Formula amount by mass percentage: 85% polyisocyanate curing agent, 15% solvent butyl acetate, carry out high-speed dispersion in a disperser, the dispersion speed is 800r / min, the dispersion time is 40 minutes, and the dispersion is uniform, that is, get Quick-drying repair varnish component B;

[0046](3) Mix components A and B evenly at a mass ratio of 6:1 to obtain a quick-drying repair high-gloss varnish. The varnish can be dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com