Method for producing low-sulfur marine fuel oil blending component by using high-sulfur heavy oil

A low-sulfur ship and fuel oil technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of high energy consumption, high viscosity of deasphalted oil, difficult realization, etc., to improve the separation speed and separation. Efficiency, improve economic efficiency, improve yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

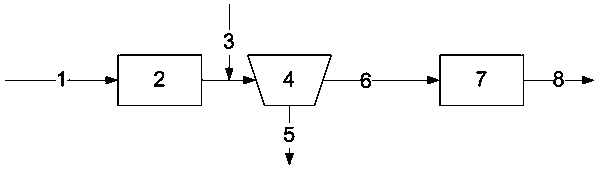

Method used

Image

Examples

Embodiment 1

[0030]This example is an implementation of producing low-sulfur marine fuel oil blending components from high-sulfur heavy oil. The vacuum residue raw material enters the visbreaking unit for visbreaking. After moderate visbreaking, a visbroken residue is obtained. Add a composite modifier to the visbreaking residue, and the added composite modifier is composed of polyacrylamide, polyaluminum chloride, N, N'-di-sec-butyl-p-phenylenediamine, p-tert-butylcatechol and The mixed composition of N,N'-disalicylidene propylenediamine, the weight ratio is 20:40:60:30:1, and the addition amount of the composite modifier is 0.05% of the weight of the vacuum residue raw material. The mixture enters a continuous settling device for continuous settling, and the operating conditions are as follows: the temperature is 80° C., and the operating pressure is the pressure at which the composite modifier is kept in a liquid phase at the operating temperature. The overflow material is obtained at...

Embodiment 2

[0034] Same as Example 1, except that the added polyacrylamide, polyaluminum chloride, N, N'-di-sec-butyl-p-phenylenediamine, p-tert-butylcatechol and N, N'-disalicylidene propane Amine mixed composition, its weight ratio is 30:60:60:30:1. Wherein, the volume yield of the overflow material obtained is 68%, and the properties of the overflow material are shown in Table 4. The reaction conditions and the test results of running for 500 hours are shown in Table 5.

Embodiment 3

[0036] Same as Example 1, except that the added polyacrylamide, polyaluminum chloride, N, N'-di-sec-butyl-p-phenylenediamine, p-tert-butylcatechol and N, N'-disalicylidene propane Amine mixed composition, its weight ratio is 20:40:80:30:2. Wherein, the volume yield of the overflow material obtained is 72%, and the properties of the overflow material are shown in Table 4. The reaction conditions and the test results of running for 500 hours are shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com