Dialysis concentrated solution distribution system

A concentrated solution and automatic preparation technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of dialysis hazards, long exhaust time, leaking, dripping and leaking at the interface, etc., to reduce the growth of microorganisms Opportunity, pipeline pressure, no suffocation, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached figure 1 -4, further explain a dialysis concentrate distribution system of the present invention.

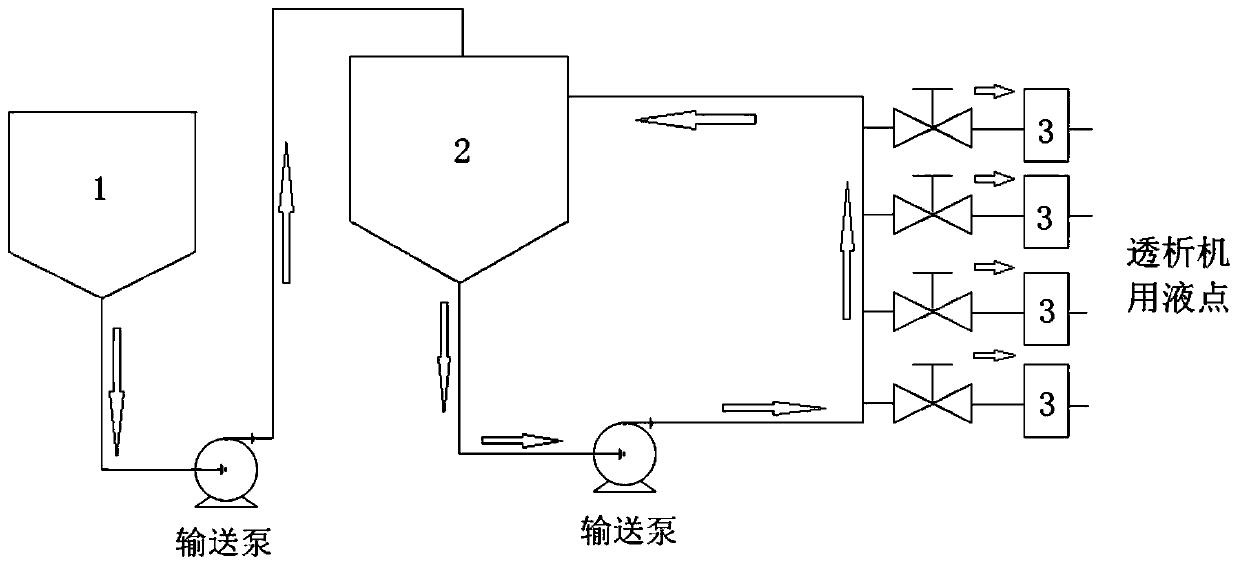

[0047] Such as figure 1 As shown, a dialysis concentrate distribution system of the present invention includes an automatic dialysis concentrate preparation device 1, a high-temperature disinfection device 2 and a zero-pressure supply device 3, and the dialysis concentrate automatic preparation device 1 is connected to the high-temperature disinfection device 2 through a pipeline. The prepared dialysis concentrate is pumped into the high-temperature disinfection device 2 through the delivery pump, and the high-temperature disinfection device 2 is connected in series in a closed liquid pipeline, and multiple zero-pressure supply devices 3 are connected in parallel on the liquid pipeline, and each A zero-pressure supply device 3 is provided with an interface connected with the liquid inlet of the kidney machine.

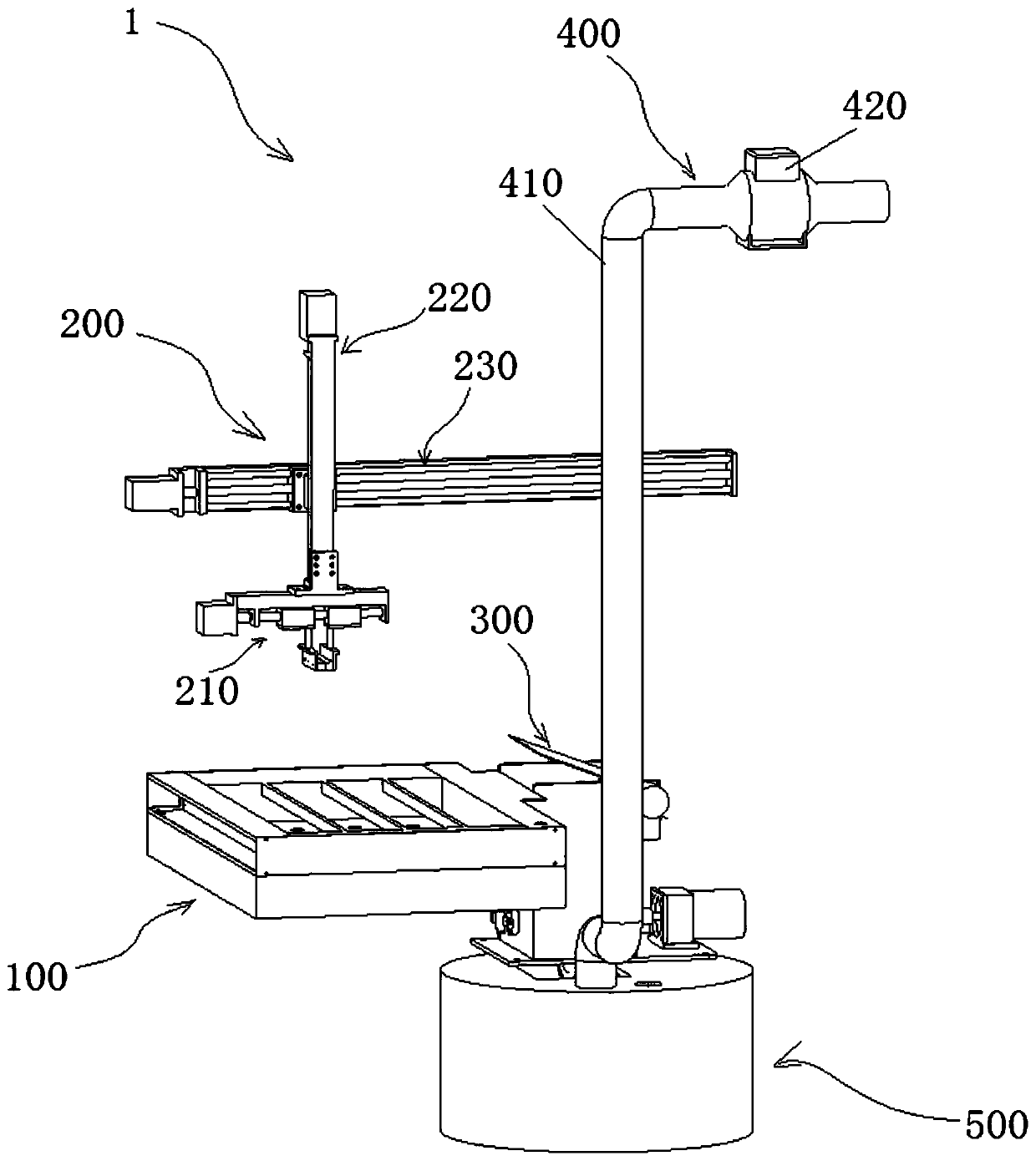

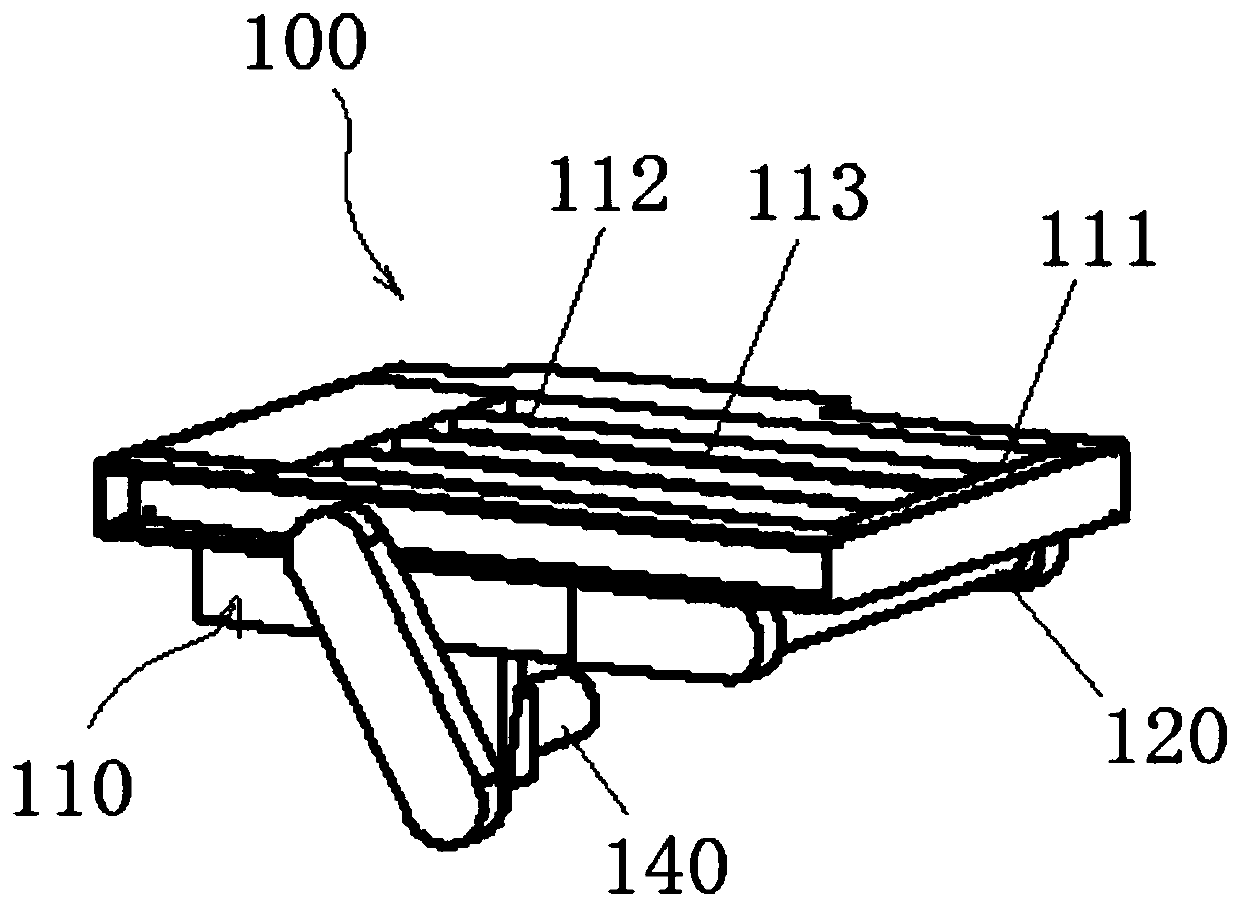

[0048] Such as diagram 2-1 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com