Method for large-area preparation of two-dimensional molybdenum telluride in-plane heterojunction with contact of metal phase and semiconductor phase and application thereof

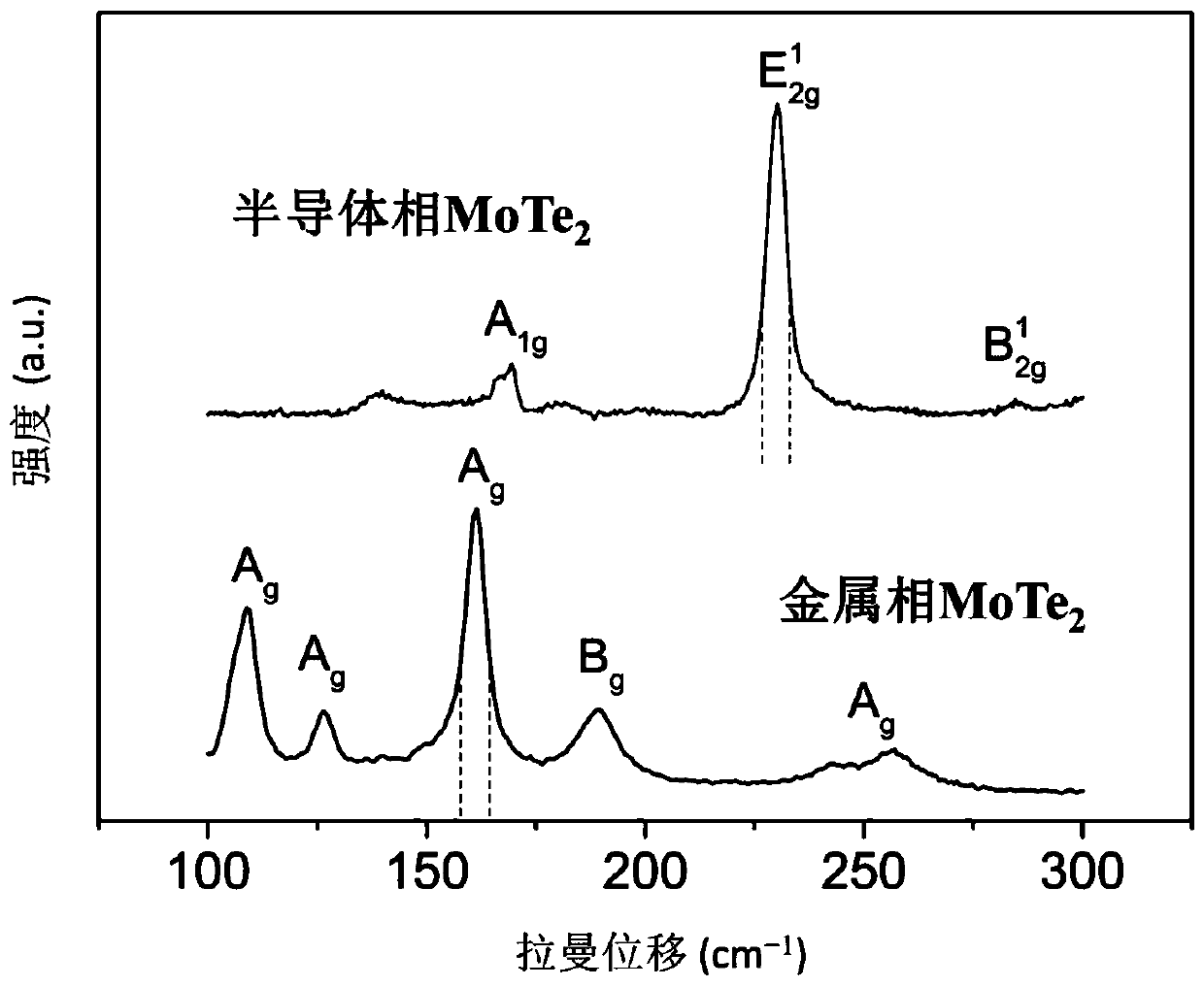

A technology for semiconductors and molybdenum telluride, which is applied in the large-area preparation of two-dimensional molybdenum telluride in-plane heterojunctions in which the metal phase and the semiconductor phase are in contact and the application field can solve problems such as inability to produce large-scale, achieve low contact resistance, Effects of improving electrical performance and improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below through specific implementation examples in conjunction with the accompanying drawings.

[0024] In this embodiment, the method for preparing a large-area in-plane heterojunction of molybdenum telluride with a metal phase in contact with a semiconductor phase includes the following steps:

[0025] 1) Provide a substrate, the substrate includes a lower conductive layer and an upper insulating layer, the lower layer is heavily doped p-type Si, and the upper layer is SiO 2 , SiO 2 The thickness is 285nm.

[0026] 2) A molybdenum thin film with a thickness of about 2 nanometers is vapor-deposited on the substrate by magnetron sputtering.

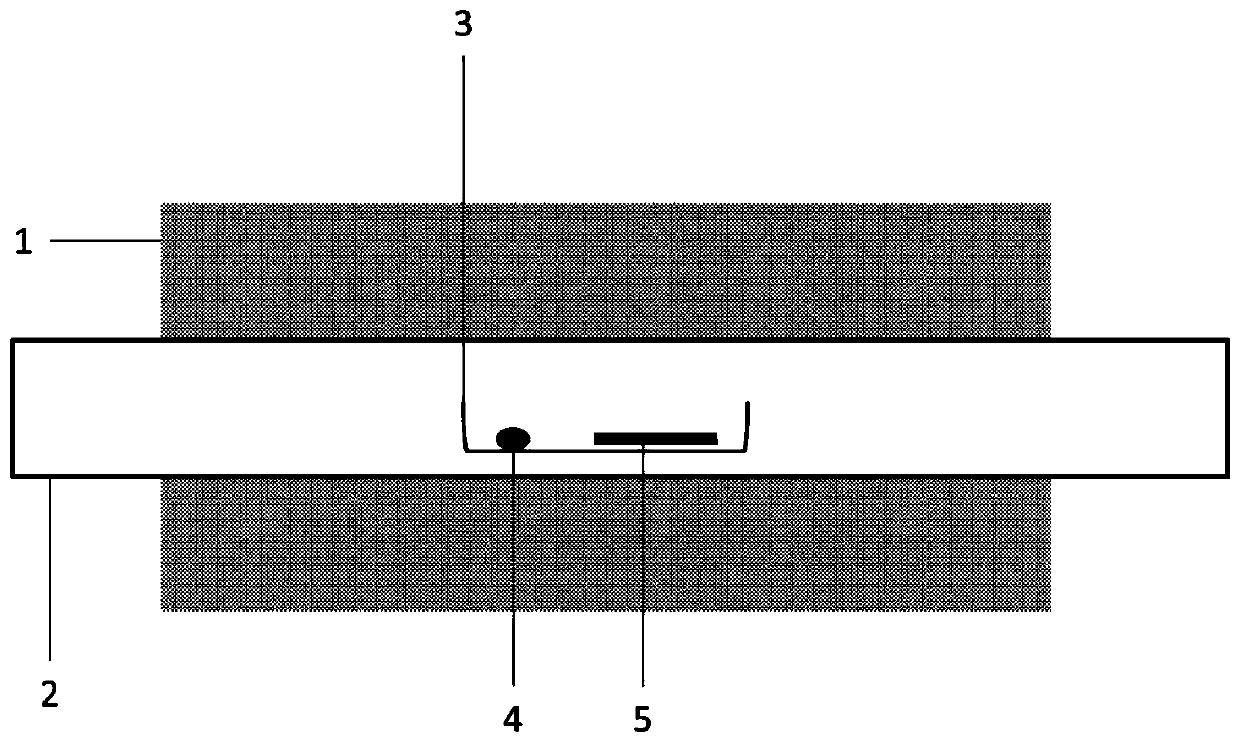

[0027] 3) see figure 1 , put the tellurium powder 4 and the substrate 5 steamed with a molybdenum thin film into the quartz boat 3, and then place them into the quartz tube 2 of the tube furnace 1. After 15 minutes of heating up, the temperature zone of the tube furnace is heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com